Busway vertical bend

A technology of bus duct and elbow, which is applied in the field of bus duct manufacturing and installation of low-voltage power transmission and distribution equipment, can solve the problems of low accuracy, uneven appearance, easy existence of leakage solder joints, etc., and achieves high protection level and simple structure. , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

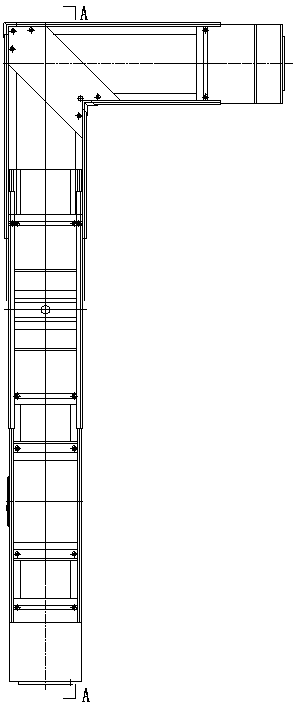

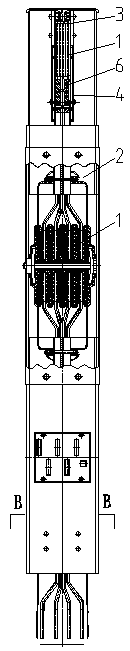

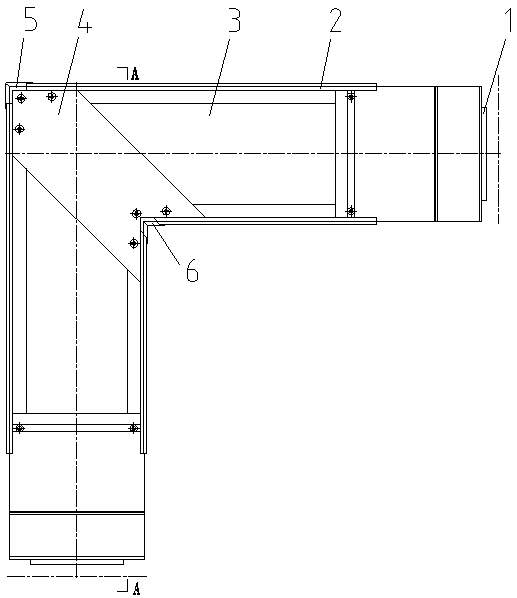

[0017] As shown in the figure, a busway vertical elbow includes a shell composed of a cover plate 2 and a side plate 3. A phase line conductor 1 is placed in the phase line placement cavity inside the shell. The phase line conductor 1 consists of two mutually perpendicular The section conductor is formed by plane welding; the side plate 3 is spliced into an L-shaped structure by the left and right parts with an oblique angle of 45°, and is fixedly connected by the side plate connector 4; the cover plate 2 is divided into an inner connector 6 and an outer connector. 5 is connected as an inner cover plate and an outer cover plate with an L-shaped structure; the side plate connector 4 has a dovetail structure, and the two sides are respectively connected with the left and right parts of the side plate 3 with an angle of 45°, and the two ends are connected with the The fixing pieces of the inner connecting piece 6 and the outer connecting piece 5 are fixedly connected; the cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com