Semiconductor module test engineering equipment integrated system and management method

A technology for module testing and equipment management, applied in transmission systems, digital transmission systems, electrical digital data processing, etc., can solve problems such as low production efficiency, large manpower, and inability to obtain production status of production lines in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

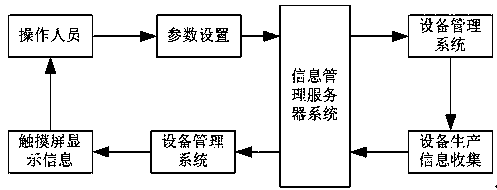

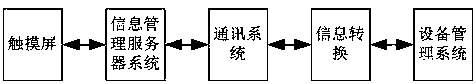

[0024] The specific embodiment of the present invention will now be described in conjunction with the accompanying drawings.

[0025] The semiconductor module testing engineering equipment integration system includes an equipment management system, an information conversion system, a communication system, an information management server system and a touch screen connected in sequence, and the touch screen is connected to the equipment management system; the equipment management system performs parameter setting and Control equipment production; the information conversion system implements signal conversion by applying the semiconductor equipment standard communication protocol; the communication system connects the information management server system and the information conversion system; the information management server system processes, calculates and stores data; The touch screen displays the information transmitted from the information management server system and sets p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com