Associated reaction-type double-blasting-bead cigarette

A reactive, bead-exploding technology, which is applied in applications, tobacco, and cigar manufacturing, can solve problems such as component changes, poor capsule connectivity, and affect the taste of cigarettes, and achieve the effect of enhancing the taste of smoking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

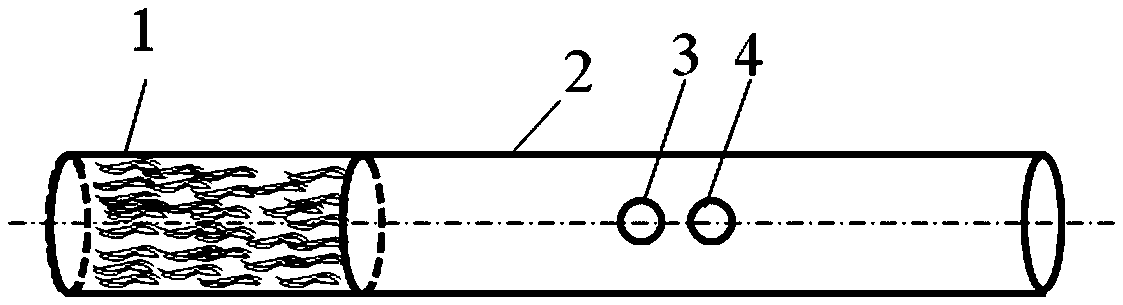

[0018] A correlative reaction type double popping bead cigarette, comprising a filter 1 and a shredded tobacco rod 2, wherein: two puffing pucks A, B (3, 4) are arranged in the shredded tobacco rod along the center line of the rod body, and two puffing pucks A The distance between , B (3, 4) is 50mm, the substance in popping bead A is acetic acid, and the substance in popping bead B is a mixture of isovaleraldehyde and ethanol. During the burning and smoking process, the two explosive beads were pinched, and a chemical reaction occurred after the two types of substances came into contact, releasing the odor of aldehydes and spices, thereby enhancing the smoking taste of the cigarette. The sensory quality evaluation results are shown in Table 1.

Embodiment 2

[0020] A correlative reaction type double popping bead cigarette, comprising a filter 1 and a shredded tobacco rod 2, wherein: two puffing pucks A, B (3, 4) are arranged in the shredded tobacco rod along the center line of the rod body, and two puffing pucks A The distance between , B (3, 4) is 50mm, the substance in popcorn A is benzoic acid, and the substance in popcorn B is a mixture of vanillin and ethylene glycol. When burning and smoking, the two explosive beads are pinched and broken, and a chemical reaction occurs after the two types of substances come into contact, releasing the odor of aldehydes and spices, thereby enhancing the smoking taste of the cigarette. The sensory quality evaluation results are shown in Table 1.

Embodiment 3

[0022] A correlative reaction type double popping bead cigarette, comprising a filter 1 and a shredded tobacco rod 2, wherein: two puffing pucks A, B (3, 4) are arranged in the shredded tobacco rod along the center line of the rod body, and two puffing pucks A The distance between , B (3, 4) is 50mm, the substance in popcorn A is glycine, and the substance in popcorn B is arabinose. When burning and smoking, the two explosive beads are crushed, and a Maillard reaction occurs after the two types of substances come into contact with each other, releasing the aroma, thereby enhancing the smoking taste of the cigarette. The sensory quality evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com