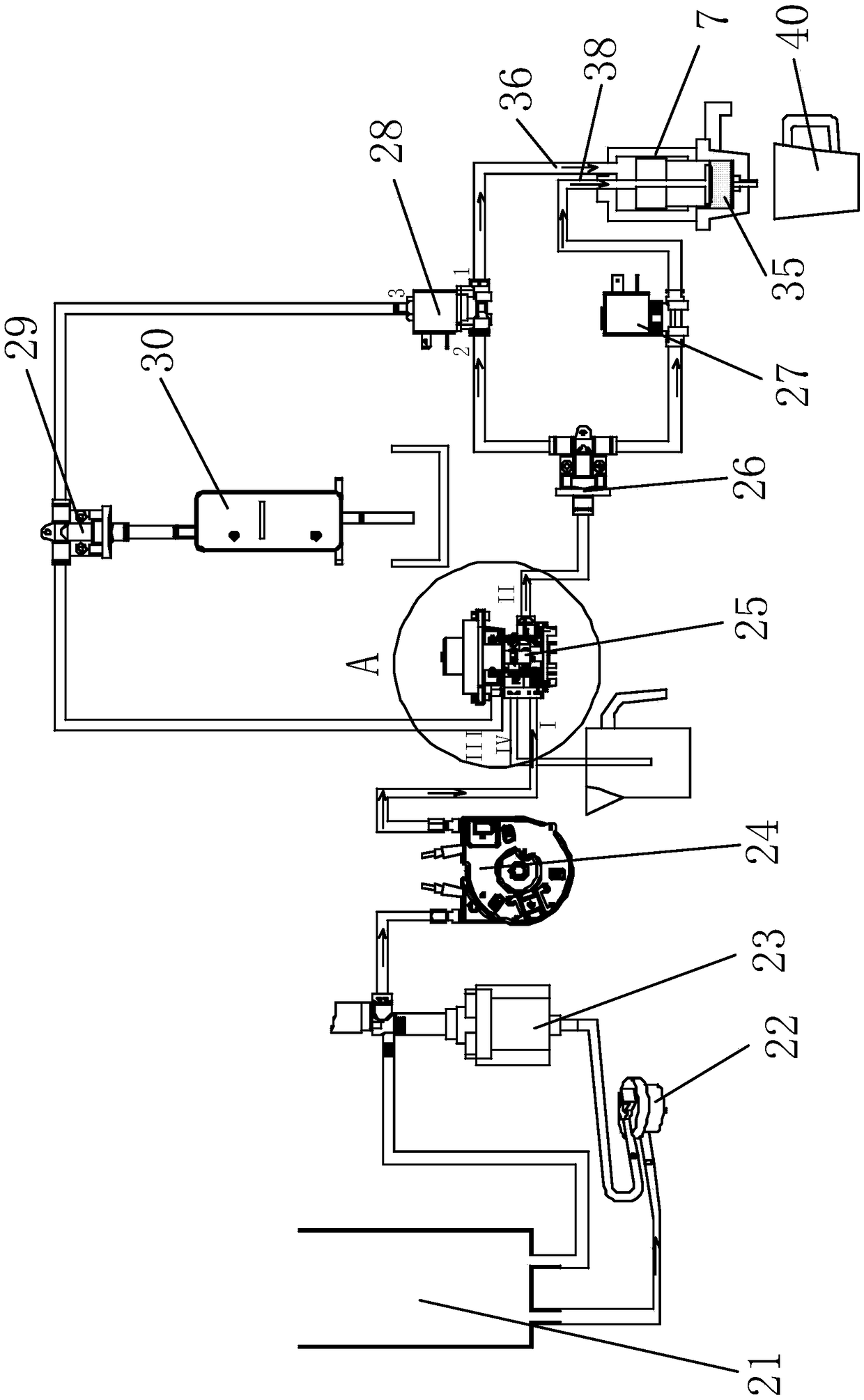

Coffee maker with automatic brewing function

A technology of automatic brewing and coffee machines, applied in the field of kitchen appliances, can solve the problems of transmission mechanism loss and high performance requirements of motors, and achieve the effects of avoiding potential safety hazards, improving compression, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below, specific embodiments of the present invention will be described in detail in conjunction with the accompanying drawings, but they are not intended to limit the present invention.

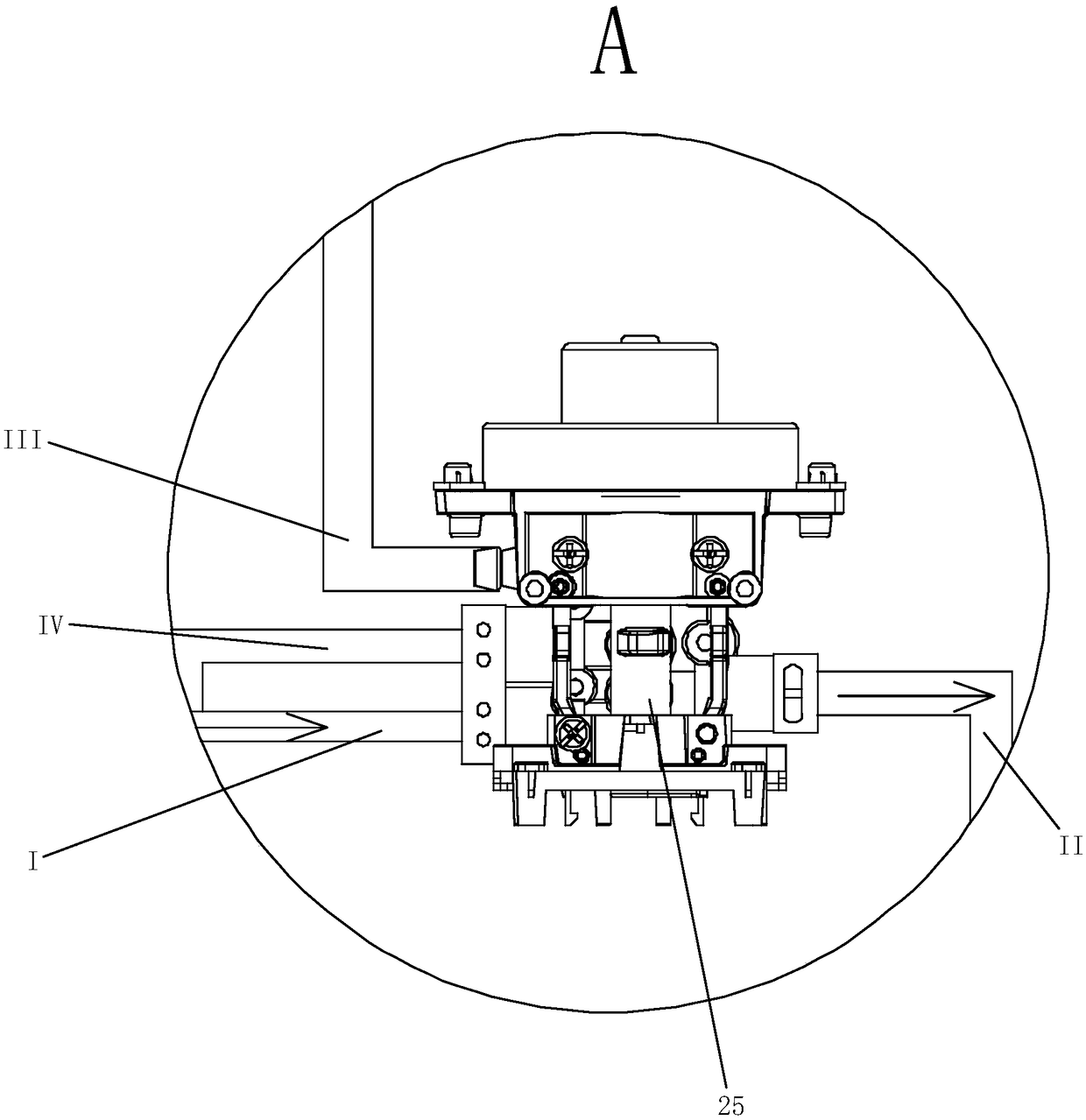

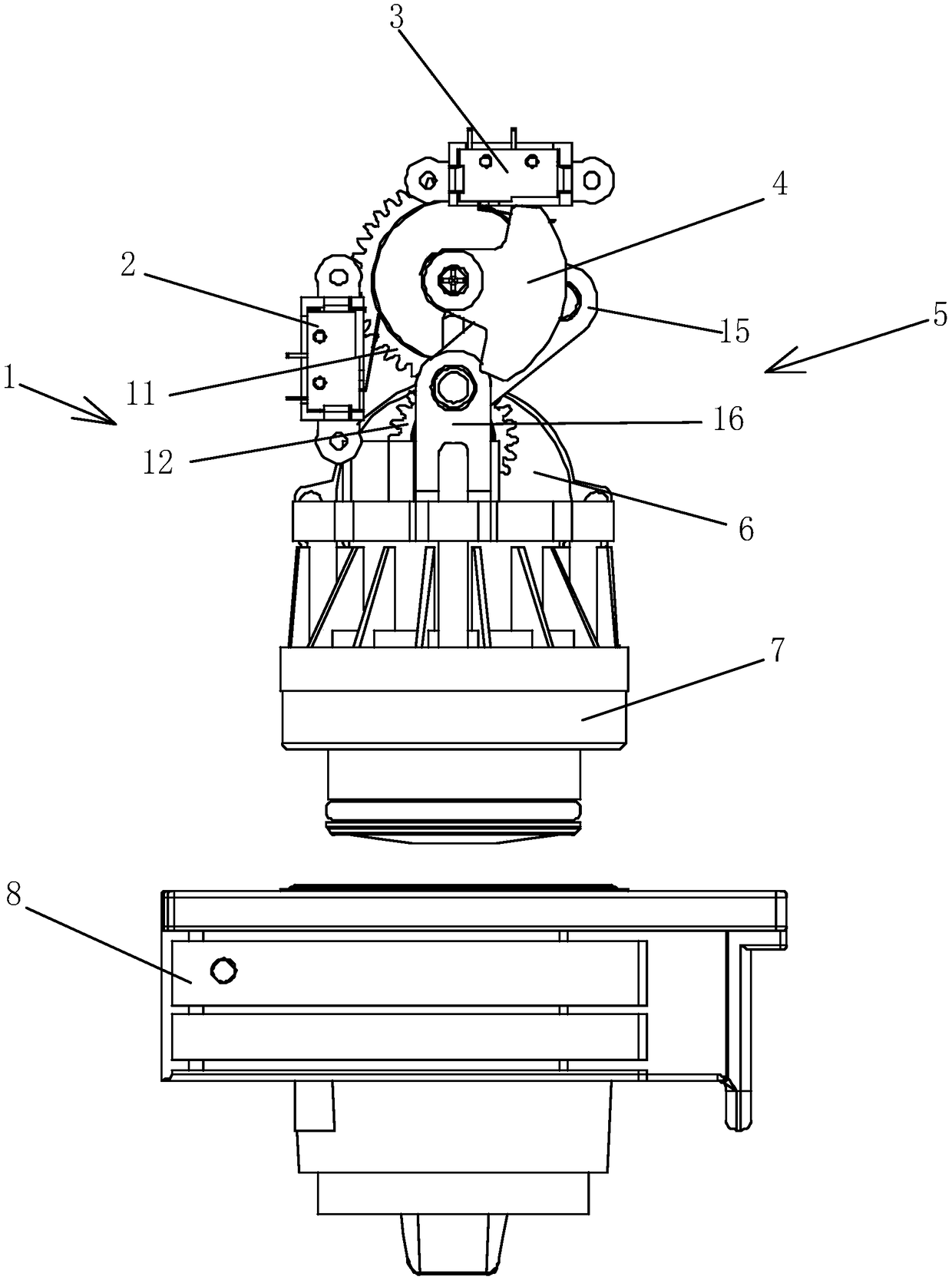

[0059] Since the coffee machine with automatic brewing function invented by the present application has made corresponding improvements to the problems existing in the prior art, it can effectively reduce the stroke requirements of the brewing head mechanism and the driving mechanism, and at the same time reduce the loss of the brewing head mechanism. From designing the structure of the brewing head to avoiding the design of the pressure relief waterway to ensure the safety of the operator during the process of providing high-pressure hot water or steam, the present invention is described below from the perspective of solving different problems.

[0060] In addition, it should be noted that all valve bodies appearing in the waterway system in this implementation, the specific water flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com