A plug-in device for preventing continuous casting slab tail billet from rising and its application method

A plug-in device and continuous casting slab technology, applied in the field of continuous steel casting, can solve the problems of production logistics and steelmaking capacity impact, short pouring length, equipment loss, etc., achieve high automation, increase liquid steel space, and prevent inflation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

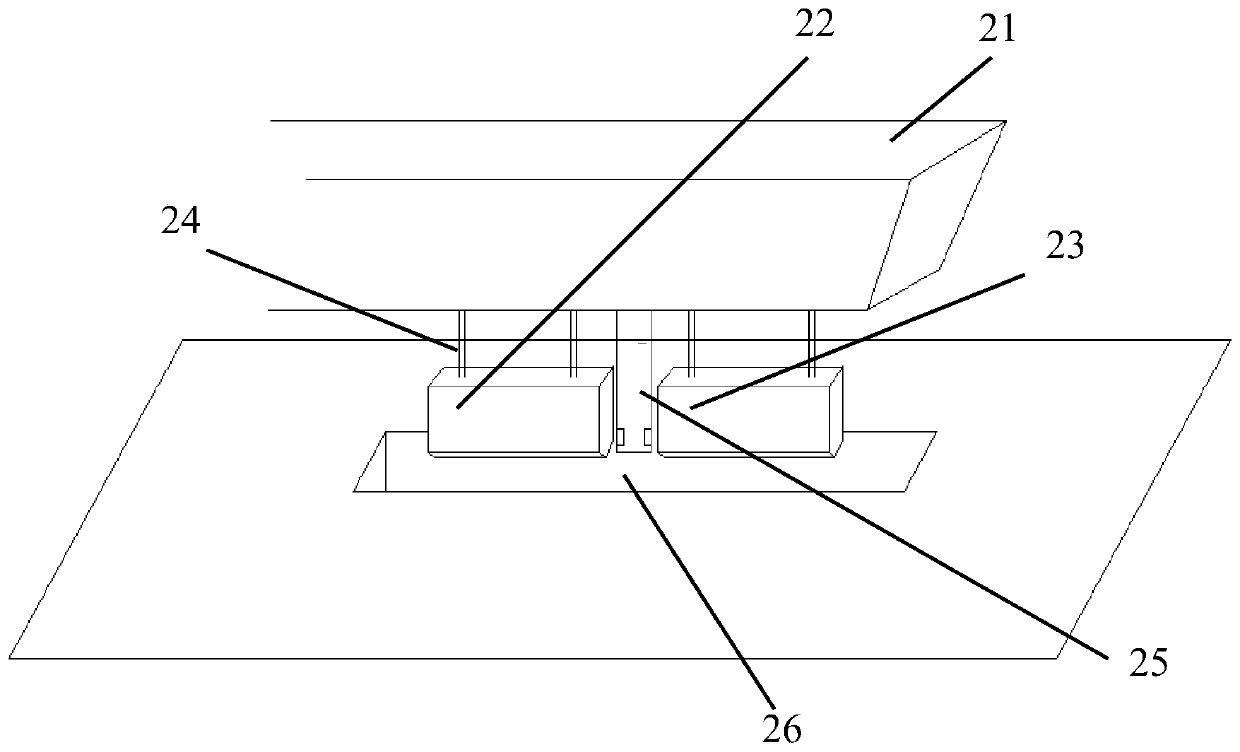

[0030] See figure 2 , which consists of two plug-ins and four landing gear connecting rod mechanisms.

[0031] The two inserts include a left insert 22 and a right insert 23, the left insert 22 and the right insert 23 are respectively installed on the tundish trolley lifting support frame 21 through two respective landing gear connecting rod mechanisms 24, and respectively Placed on both sides of the submerged nozzle 25 of the tundish, the trolley lifting support frame 21 is located at the bottom of the tundish.

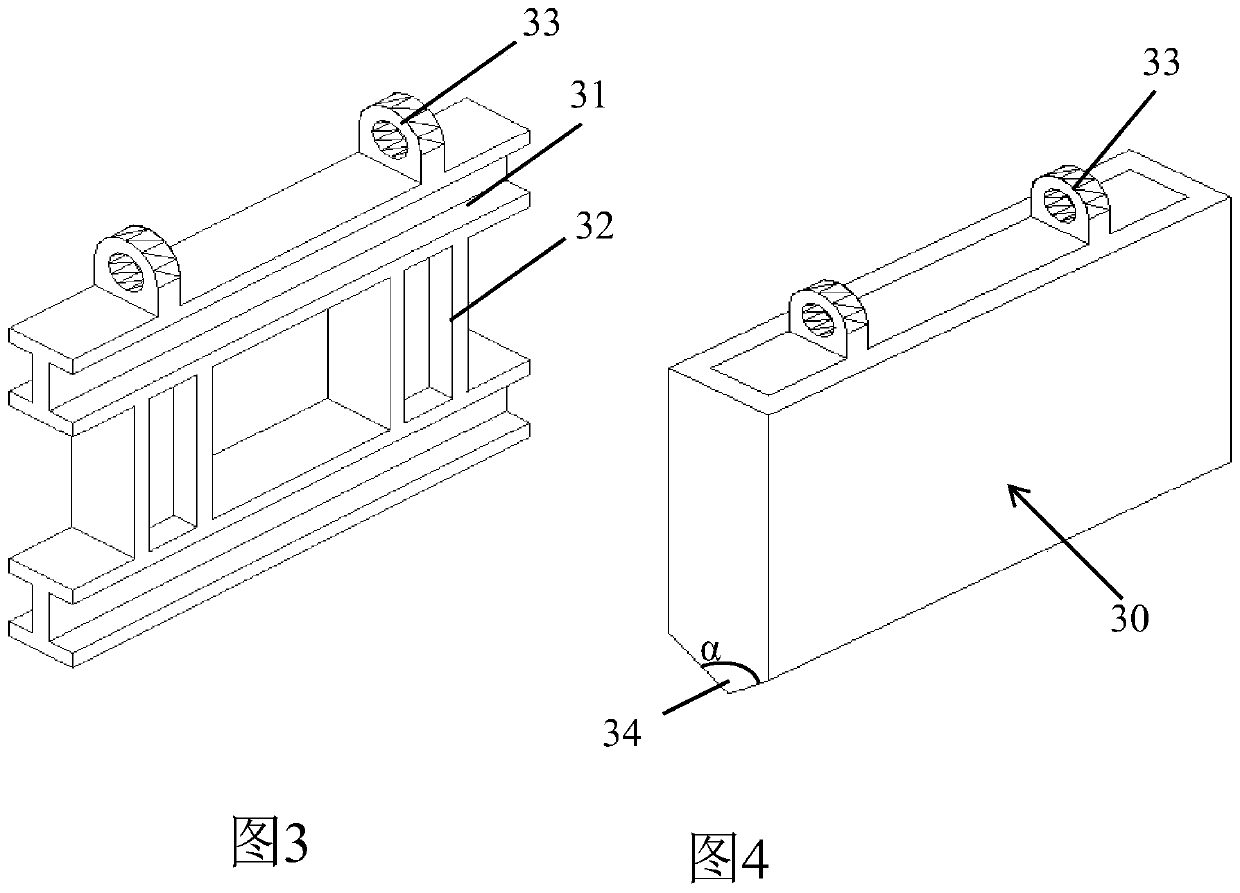

[0032] The left side plug-in 22 and the right side plug-in 23 have the same structure, and are collectively referred to as plug-in 30, as image 3 As shown, the inside of the plug-in 30 is a rectangular keel frame formed by welding structural steel; the keel frame is composed of two I-beams 31 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com