Printing apparatus and control method

A technology of printing device and control method, which is applied in the direction of printing device, printing, power transmission device, etc., and can solve problems such as time-consuming, unresolved, and increased product size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, embodiments of the present invention will be described with reference to the drawings. However, such embodiment examples do not limit the technical scope of the present invention. It should be noted that in the drawings, the same reference numerals or reference signs are attached to the same or similar parts for description.

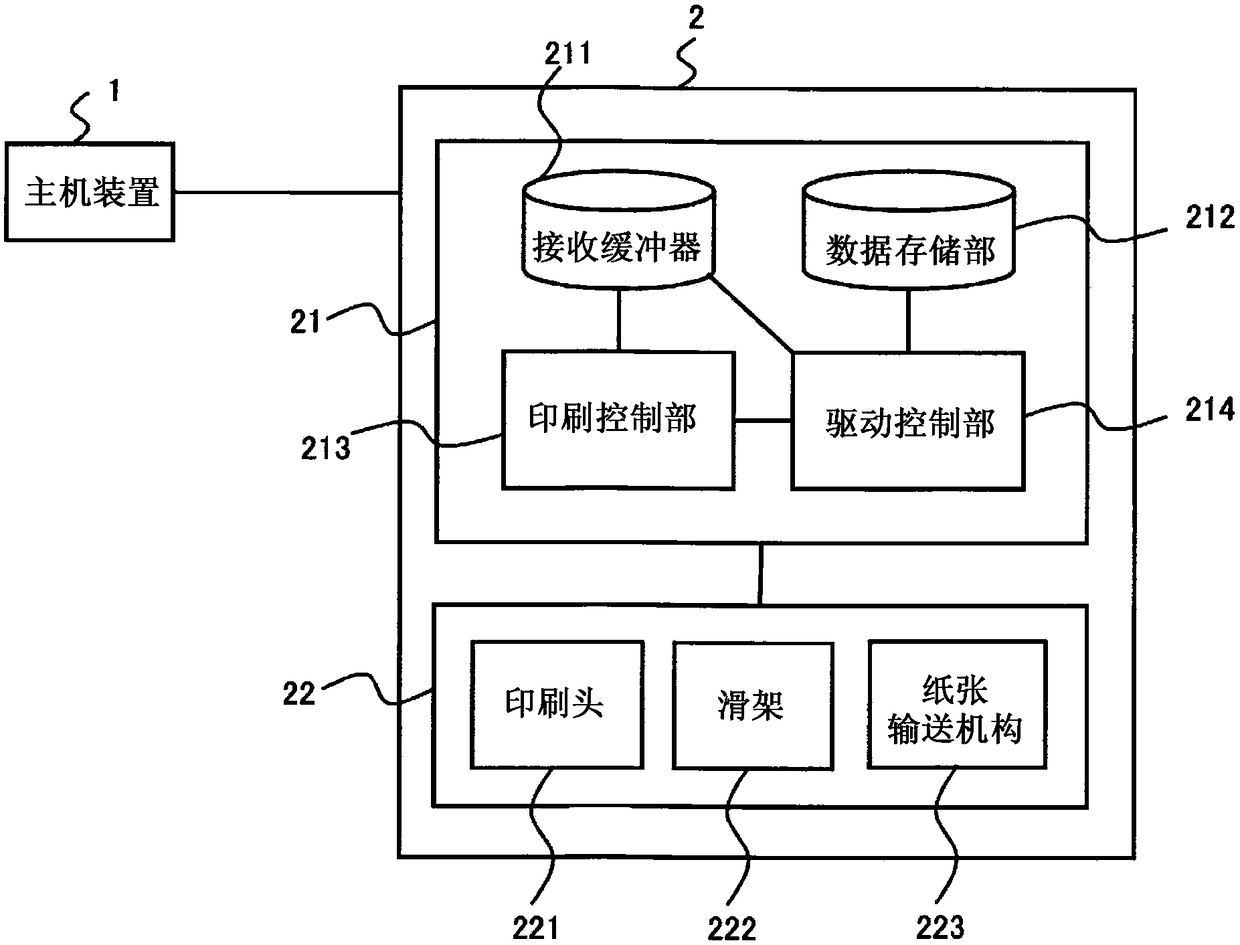

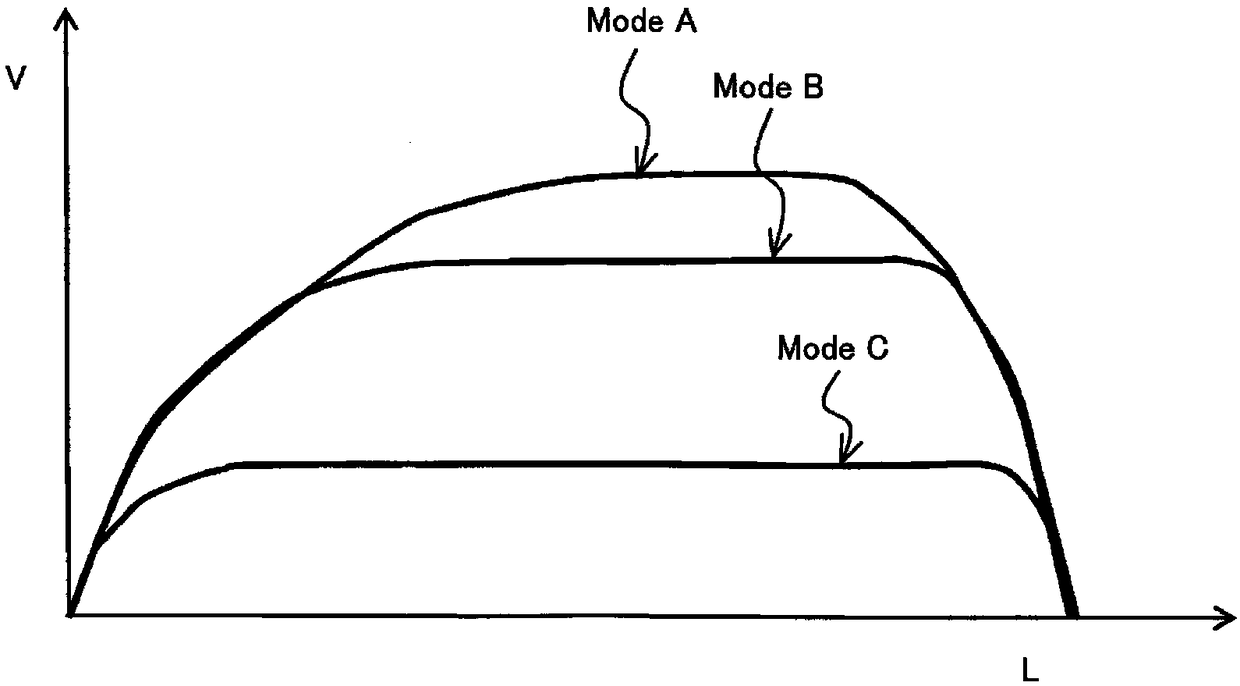

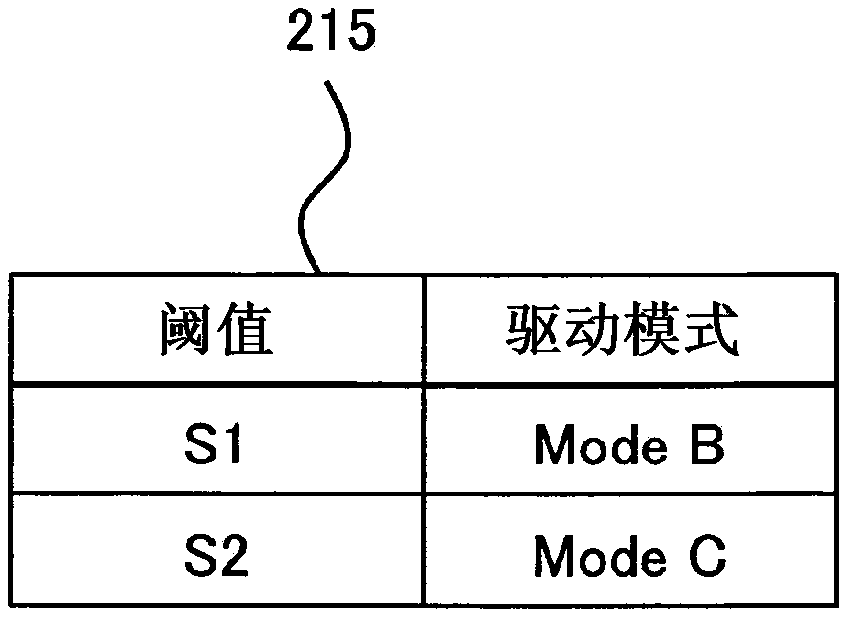

[0035] figure 1 It is a configuration diagram related to an embodiment example of a printing apparatus to which the present invention is applied. figure 1 The illustrated printer 2 is a printing device to which the present invention is applied. In this printer 2 , a carriage 222 on which a print head 221 is mounted moves in the scanning direction SD to print on paper PM. The present printer 2 has a plurality of driving modes with different speeds related to the movement of the carriage 222. During printing, the predicted movement is obtained for each line (one scan) based on the current position of the carriage 222 and the print dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com