Composite glass having built-in aerogel, and preparation method thereof

A composite glass and airgel technology, applied in chemical instruments and methods, glass/slag layered products, lamination devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

[0040] An example of the present invention is as follows, a method for preparing composite glass with built-in airgel, comprising the following steps:

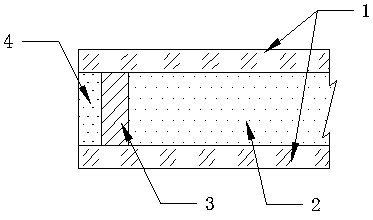

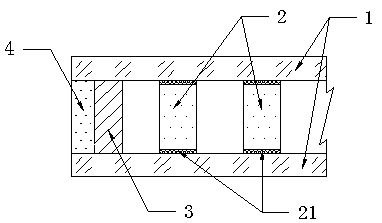

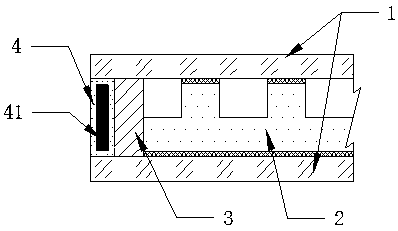

[0041] (1) Lay the airgel support body 2 on the central surface of the glass 1, lay the spacer support body 3 on the surrounding edge of the glass 1, and then place another piece of glass 1 in parallel on the airgel support body 2 and On the spacer support body 3;

[0042] (2) In a vacuum environment, at the U-shaped joint formed between the two pieces of glass 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com