Connecting assembly

A technology for connecting components and components, applied in the direction of connecting components, non-mechanical drive clutches, fluid drive clutches, etc., can solve problems such as time-consuming work steps, and achieve the effect of saving assembly costs, saving additional materials, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

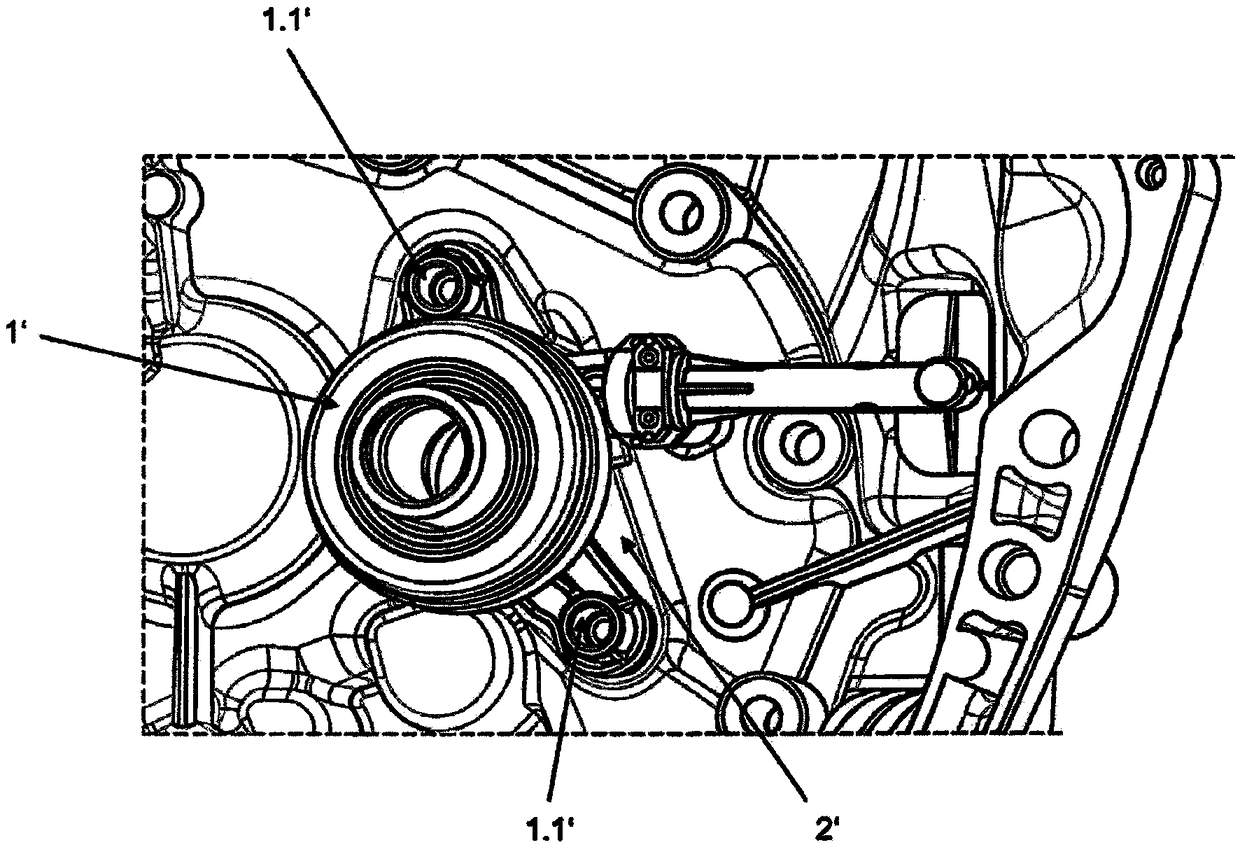

[0035] figure 1 The CSC is shown fixed to the clutch housing 2' in a typical variant according to the prior art. The CSC here has a cylinder housing 1' on which two webs 1.1' pointing radially outward are arranged. Screw the cylinder housing 1' onto the clutch housing 2' on the connecting plate 1.1'.

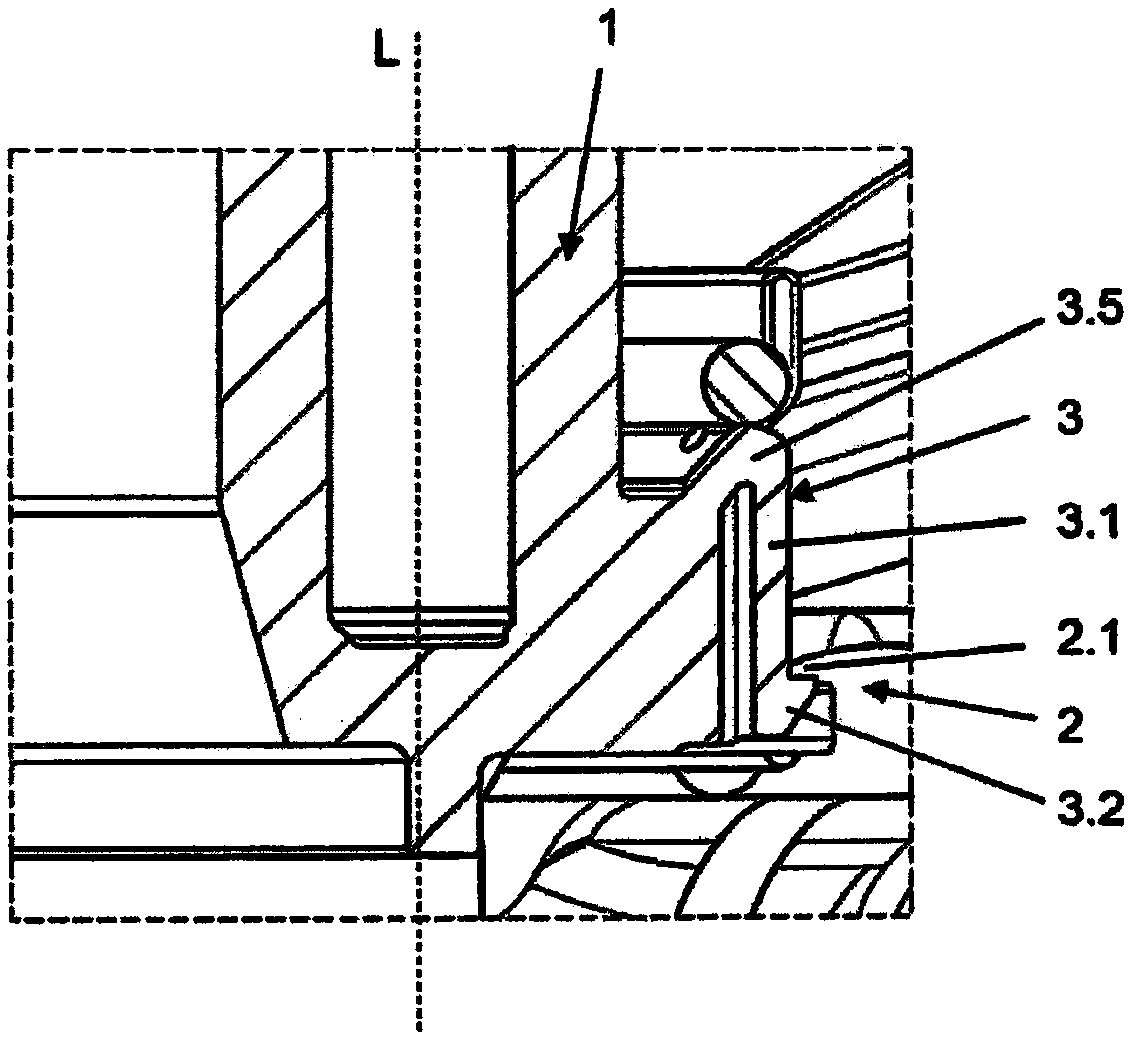

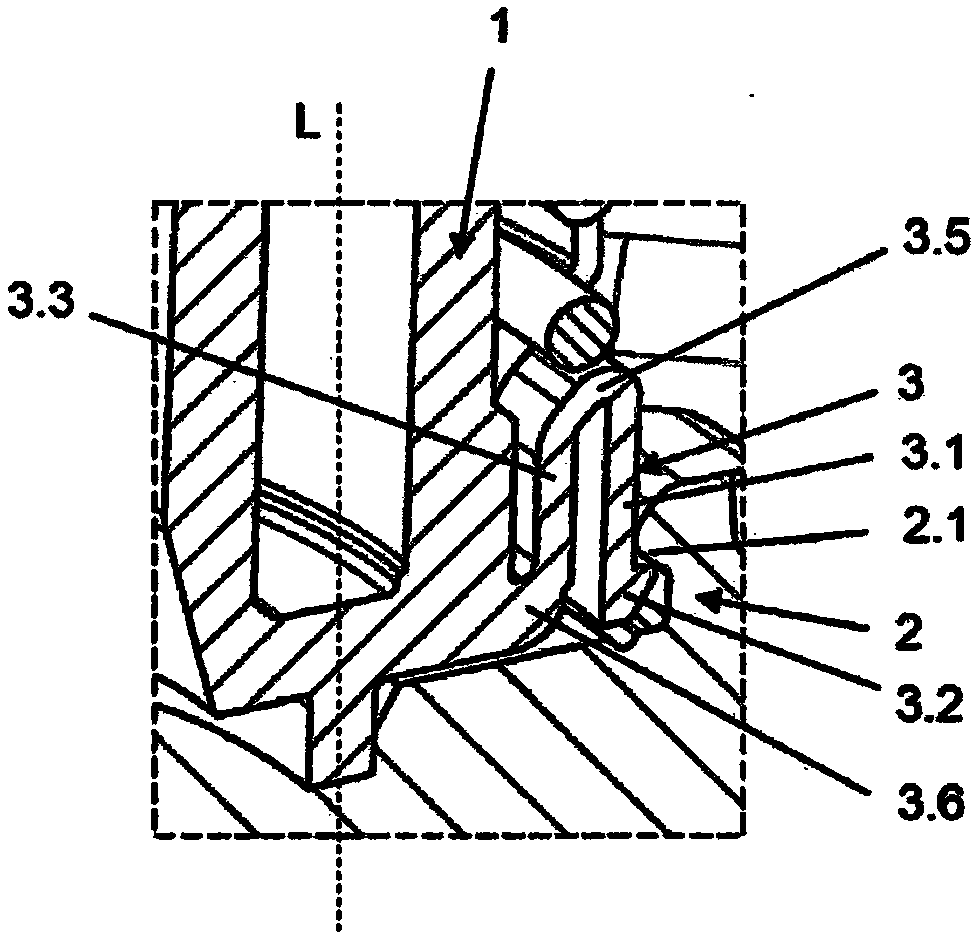

[0036] exist figure 2 A longitudinal section through a fastening element 3 according to the invention is shown in . In this case, the fastening element 3 is arranged radially outward on the cylinder housing 1 . The fastening element 3 has elastically configured flanks 3 . 1 extending parallel to the longitudinal axis L of the cylinder housing 1 , on whose free ends radially outwardly directed snap-in hooks 3 . 2 are arranged. The flanks 3.1 are connected to the cylinder housing 1 via a first connecting region 3.5. The flanks 3.1 can be compressed radially inwards during assembly and spring back into their initial position after assembly, in which they engage in correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com