Method and device for physical simulation of shift fork

A technology of physical simulation and position information, applied in the field of shifting forks, can solve the problems of simulating the shifting forks, prolonging the development cycle of TCU software, and failing to expose the loopholes in the control and diagnosis scheme of the shifting forks, so as to achieve the effect of improving the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The existing physical simulation method of shift fork cannot simulate the working process of the shift fork well, resulting in the inability to expose the loopholes in the shift fork control and diagnosis scheme during the TCU software development stage, resulting in the need for repeated testing during the TCU software development process, making the TCU The software development cycle is extended.

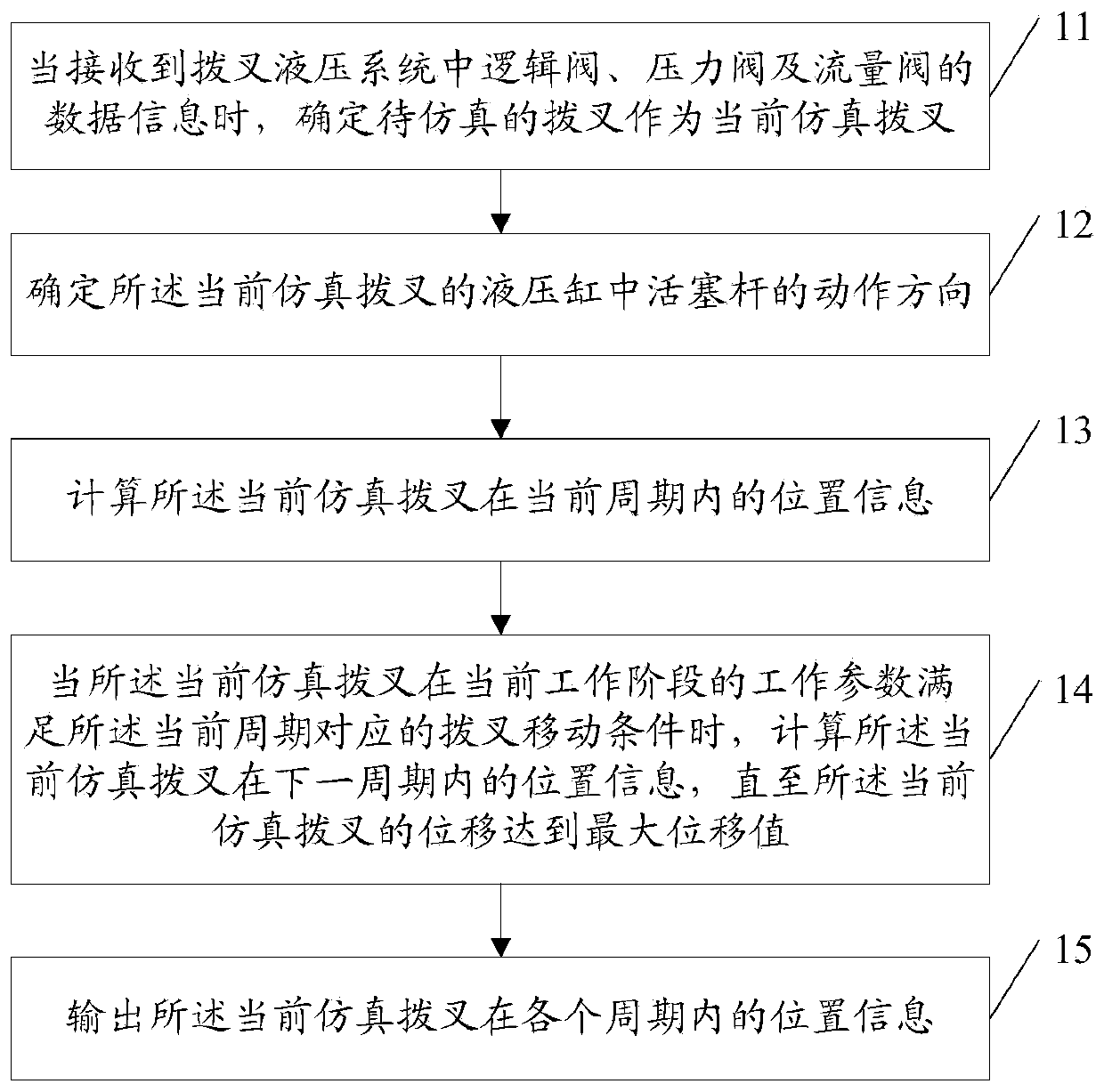

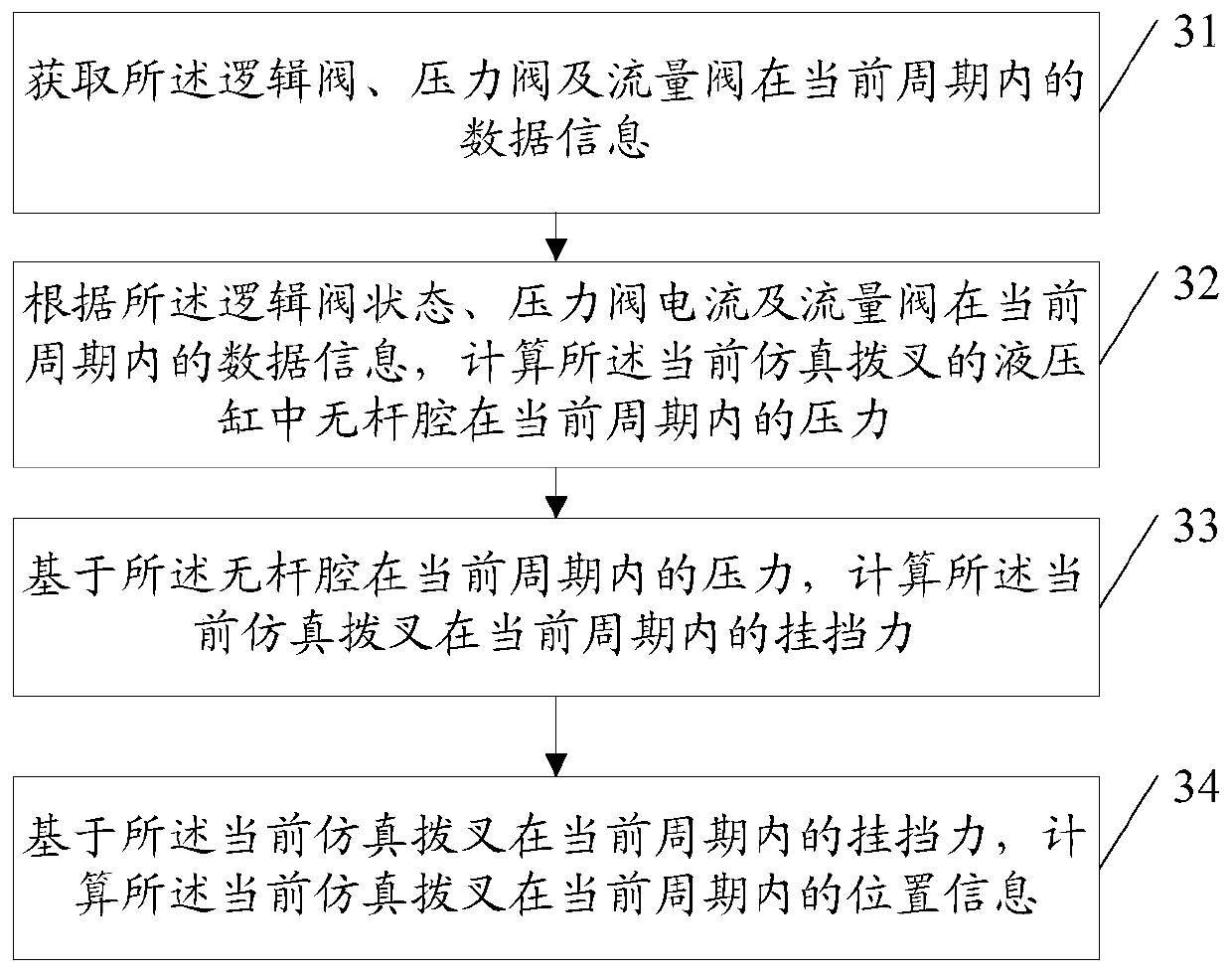

[0048] In view of the above problems, the embodiment of the present invention provides a physical simulation method of the shift fork, which divides the working process of the shift fork into at least two working stages according to the position information of the shift fork in advance, and calculates the time period of each cycle of the shift fork in different working stages. The position information of the inner shift fork can more accurately simulate the working process of the shift fork, and can accurately expose the loopholes in the shift fork control and diagnosis sche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com