Insulation detection method, system and device for lifting appliance and storage medium

A detection method and detection system technology, which is applied in the direction of measuring devices, measuring device casings, and testing dielectric strength, can solve problems such as low detection efficiency and poor timeliness, and achieve the effects of ensuring safety, avoiding short circuits, and improving timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

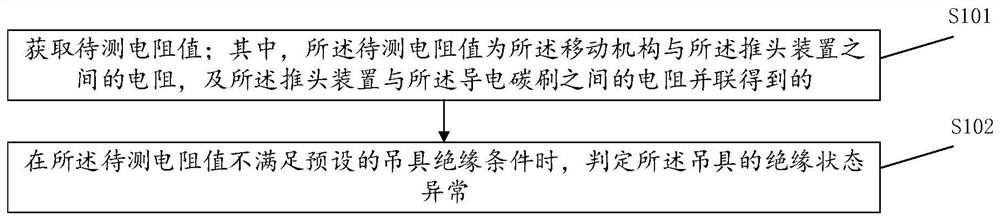

[0045] see image 3 , is a schematic flowchart of an insulation detection method for a spreader provided by an embodiment of the present invention. The insulation detection method of the spreader includes step S101 to step S102:

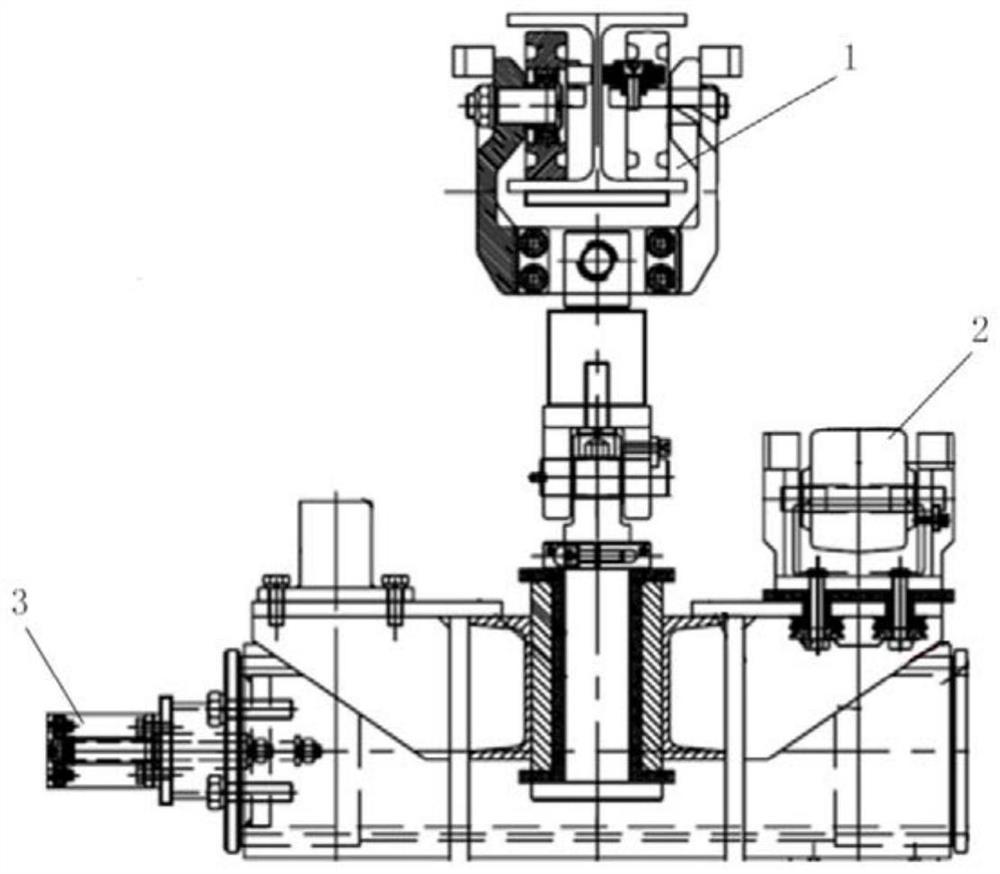

[0046] S101. Obtain the resistance value to be measured; wherein, the resistance value to be measured is obtained by connecting the resistance between the moving mechanism 1 and the pusher device 2, and the resistance between the pusher device 2 and the conductive carbon brush 3 in parallel;

[0047] In this example, see Figure 4 , is the equivalent schematic diagram of the resistance to be measured. Wherein, the resistance value to be measured is R between the moving mechanism 1 and the pusher device 2 1 , the resistance between the pusher device 2 and the conductive carbon brush 3 is R 2 . The resistance to be measured is R 1 with R 2 The parallel resistance between, that is, the actual measured resistance R 实 . due to R 1 with R2 There ...

Embodiment 2

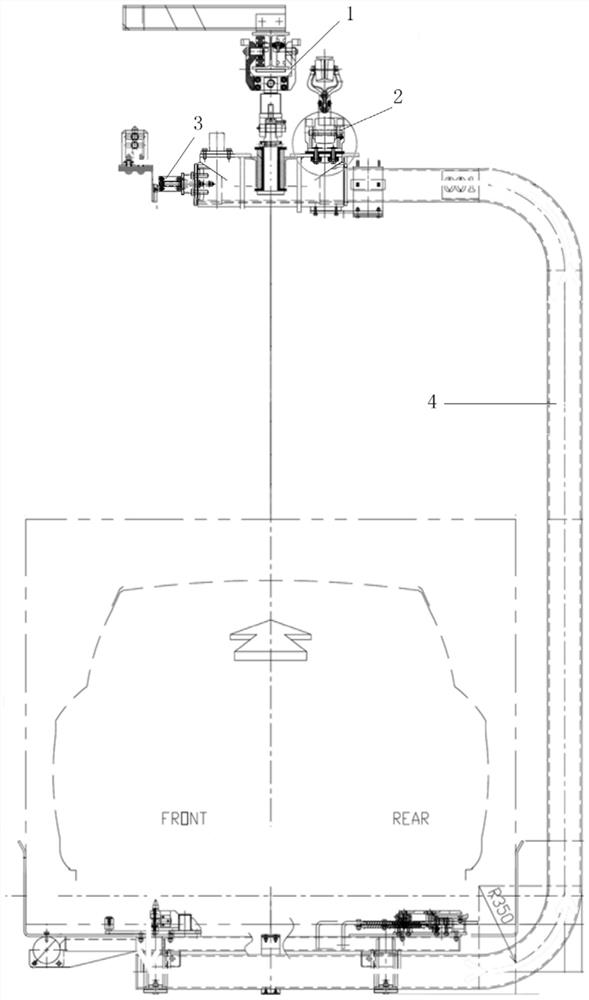

[0061] see Figure 6 , is a schematic structural diagram of an insulation detection system for a spreader provided by an embodiment of the present invention. The spreader includes: moving mechanism 1, push head device 2 and conductive carbon brush 3;

[0062] The system includes: a relay 201, and a measuring instrument 202 for obtaining the resistance value to be measured;

[0063] The first measuring end of the measuring instrument 202 is connected with the conductive carbon brush 3, and the second measuring end of the measuring instrument 202 is connected with the moving mechanism 1 and the pushing device 2 respectively; the signal output end of the measuring instrument 202 is connected with the signal input end of the relay 201 ;

[0064] When the measurement signal input by the measuring instrument 202 received by the relay 201 does not meet the preset insulation condition of the spreader, the normally open contact of the control relay 201 is closed;

[0065] Wherein, t...

Embodiment 3

[0075] see Figure 8 , is a structural schematic diagram of an insulation detection device for a spreader provided by an embodiment of the present invention. Controls include:

[0076] The data acquisition module 301 is used to obtain the resistance value to be measured; wherein, the resistance value to be measured is obtained by connecting the resistance between the moving mechanism and the pusher device, and the resistance between the pusher device and the conductive carbon brush in parallel;

[0077]The judging module 302 is configured to judge that the insulation state of the spreader is abnormal when the resistance value to be measured does not meet the preset insulation condition of the spreader.

[0078] Further, it also includes: an alarm module, which is used to issue an alarm after determining that the resistance value to be measured does not meet the preset insulation condition of the spreader.

[0079] Further, the preset insulation condition of the spreader incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com