Extending-and-contracting type valve for large-diameter pipe

A large-diameter tube, telescopic technology, applied in the directions of lift valves, valve details, valve devices, etc., can solve the problems of seal reliability damage, valve leakage, damage, etc., and achieve the effect of saving living costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

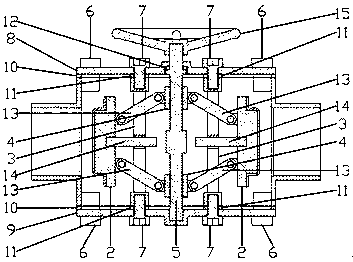

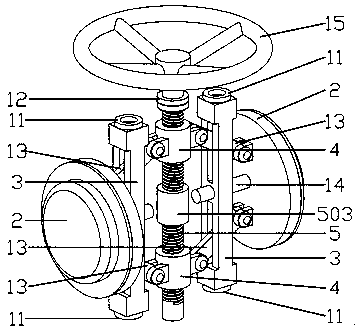

[0025] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings: It should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

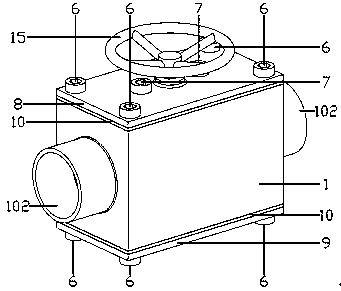

[0026] Such as Figures 1 to 9As shown, a telescopic valve for large-diameter pipes includes a valve body 1, an upper end cover 8 and a lower end cover 9 are respectively arranged on the upper and lower sides of the valve body 1, and the edge of the upper end cover 8 is in contact with the valve body. A first liner 10 is provided between the edge of the upper surface of the body 1, and a first liner 10 is also provided between the edge of the lower end cover 9 and the edge of the lower surface of the valve body 1; , The first gasket 10 and the valve body 1 are also fixedly connected by the first screw 6, and the lower end cover 9, the first gasket 10 and the valve body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com