Adjustable television bracket

A technology for TV brackets and racks, which is applied to TVs, color TVs, machine sets/stands, etc., and can solve problems such as manual adjustment, inconvenient adjustment of flat-panel TV brackets, and inability to automatically adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

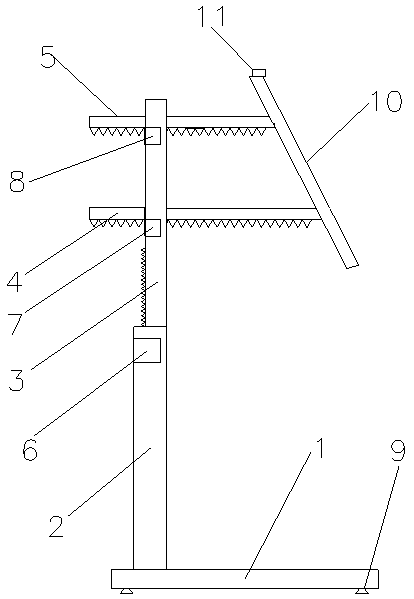

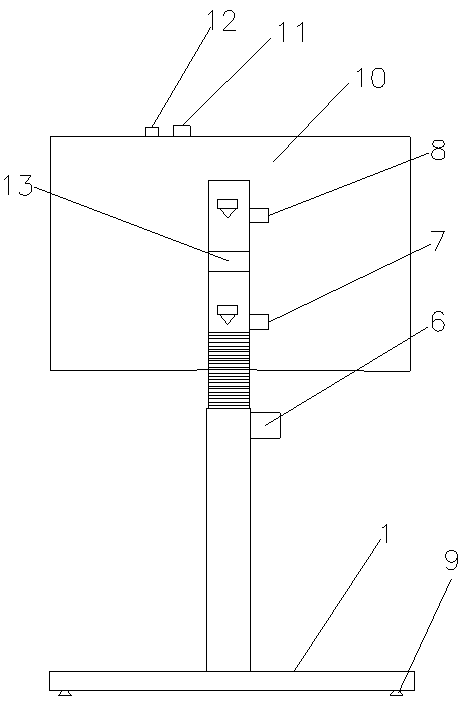

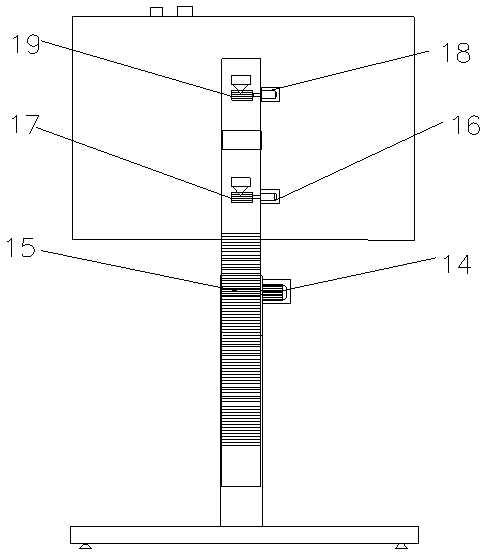

Method used

Image

Examples

Embodiment 1

[0049] User A, male, with a height of 175cm, a weight of 68KG, and a normal body; the frame adjustment process during use includes:

[0050] S1: User A stands on the rack base 1, the control unit obtains the data of the pressure sensor 9 and calculates the offset position of the center of gravity of the rack base 1 and the weight of user A, and obtains the deviation of the center of gravity of the rack base 1 In the front, the weight of user A is 68KG;

[0051] S2: The control module 13 sends operation instructions to the front and rear motors 18, the front and rear motors 18 work, the control module 13 drives the front and rear racks 5 to move forward, and detects the data of the pressure sensors 9 during the adjustment process. When the data of the four pressure sensors 9 are consistent, The center of gravity adjustment is completed;

[0052] S3: According to: male: height (cm)-105=standard weight (kg), the control unit calculates that the estimated height of the user is 17...

Embodiment 2

[0058] User B, male, with a height of 165cm, a weight of 68KG, and a short and fat body; the frame adjustment process during use includes:

[0059] S1: User B stands on the rack base 1, the control unit obtains the data of the pressure sensor 9 and calculates the offset position of the center of gravity of the rack base 1 and the weight of user B, and obtains the deviation of the center of gravity of the rack base 1 In front, the weight of user B is 68KG;

[0060] S2: The control module 13 sends operation instructions to the front and rear motors 18, the front and rear motors 18 work, the control module 13 drives the front and rear racks 5 to move forward, and detects the data of the pressure sensors 9 during the adjustment process. When the data of the four pressure sensors 9 are consistent, The center of gravity adjustment is completed;

[0061] S3: According to: male: height (cm)-105=standard weight (kg), the control unit calculates that the estimated height of the user is...

Embodiment 3

[0067] User C, female, with a height of 165cm, a weight of 45KG, and a thin and tall body; the frame adjustment process during use includes:

[0068] S1: User C stands on the rack base 1, the control unit obtains the data from the pressure sensor 9 and calculates the offset position of the center of gravity of the rack base 1 and the weight of user C, and obtains that the center of gravity of the rack base 1 is slightly Leaning forward, the weight of user C is 45KG;

[0069] S2: The control module 13 sends operation instructions to the front and rear motors 18, the front and rear motors 18 work, the control module 13 drives the front and rear racks 5 to move forward slightly, and detects the data of the pressure sensors 9 during the adjustment process. When the data of the four pressure sensors 9 are consistent , the center of gravity adjustment ends;

[0070] S3: According to: female: height (cm)-100=standard weight (kg), the control unit calculates that the estimated height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com