Performance detection device and detection method for air float ball bearing

A detection device and ball bearing technology, applied in the field of precision measurement, can solve the problems of changing the air-film gap, unable to judge the working state of the air-floating ball bearing, and distortion of the pressure distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

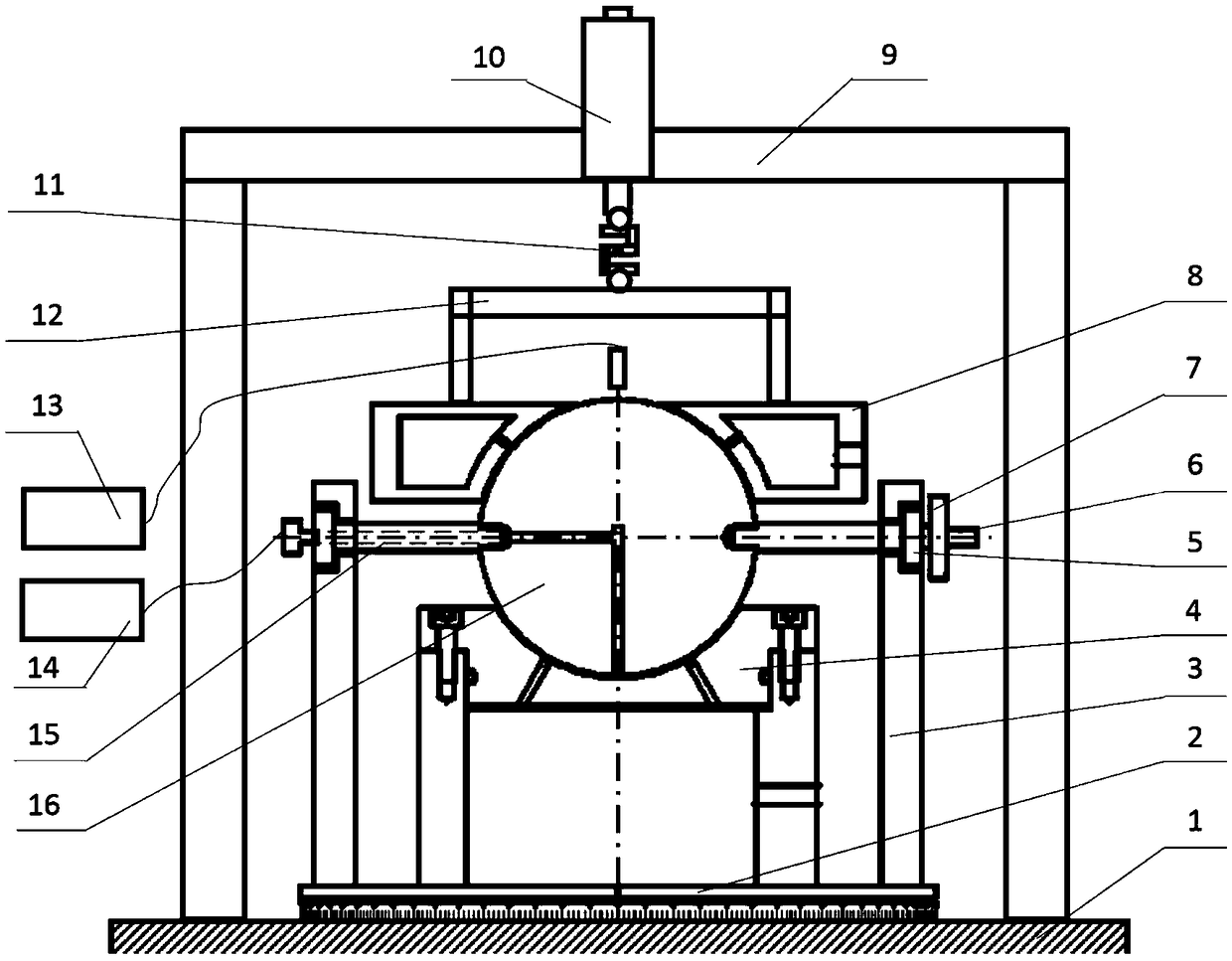

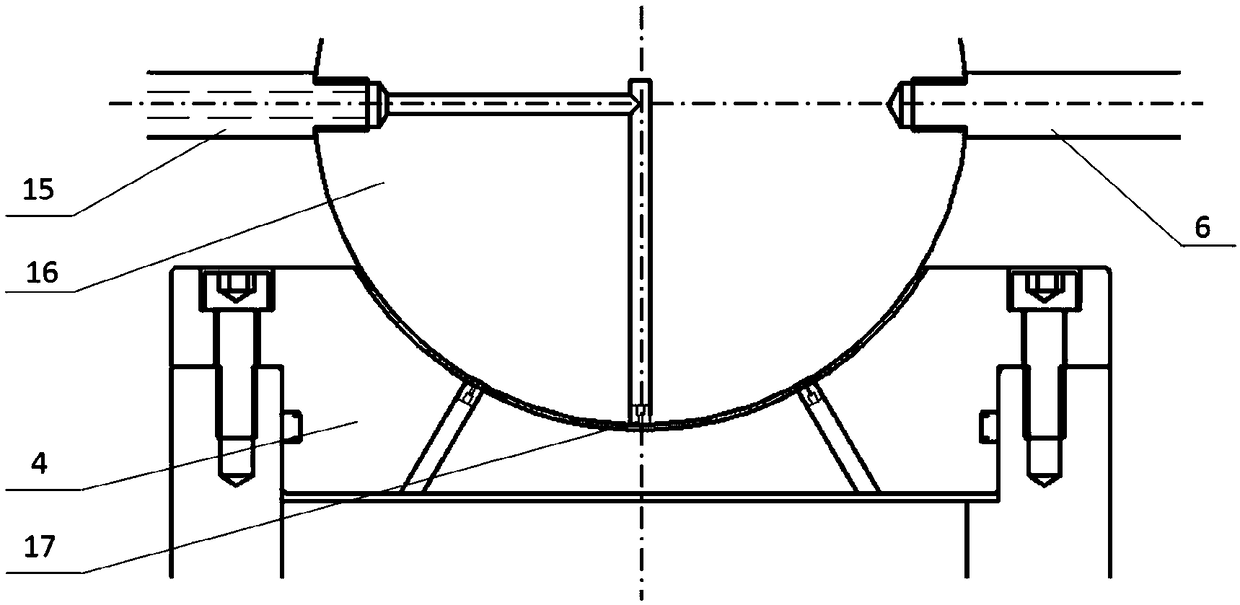

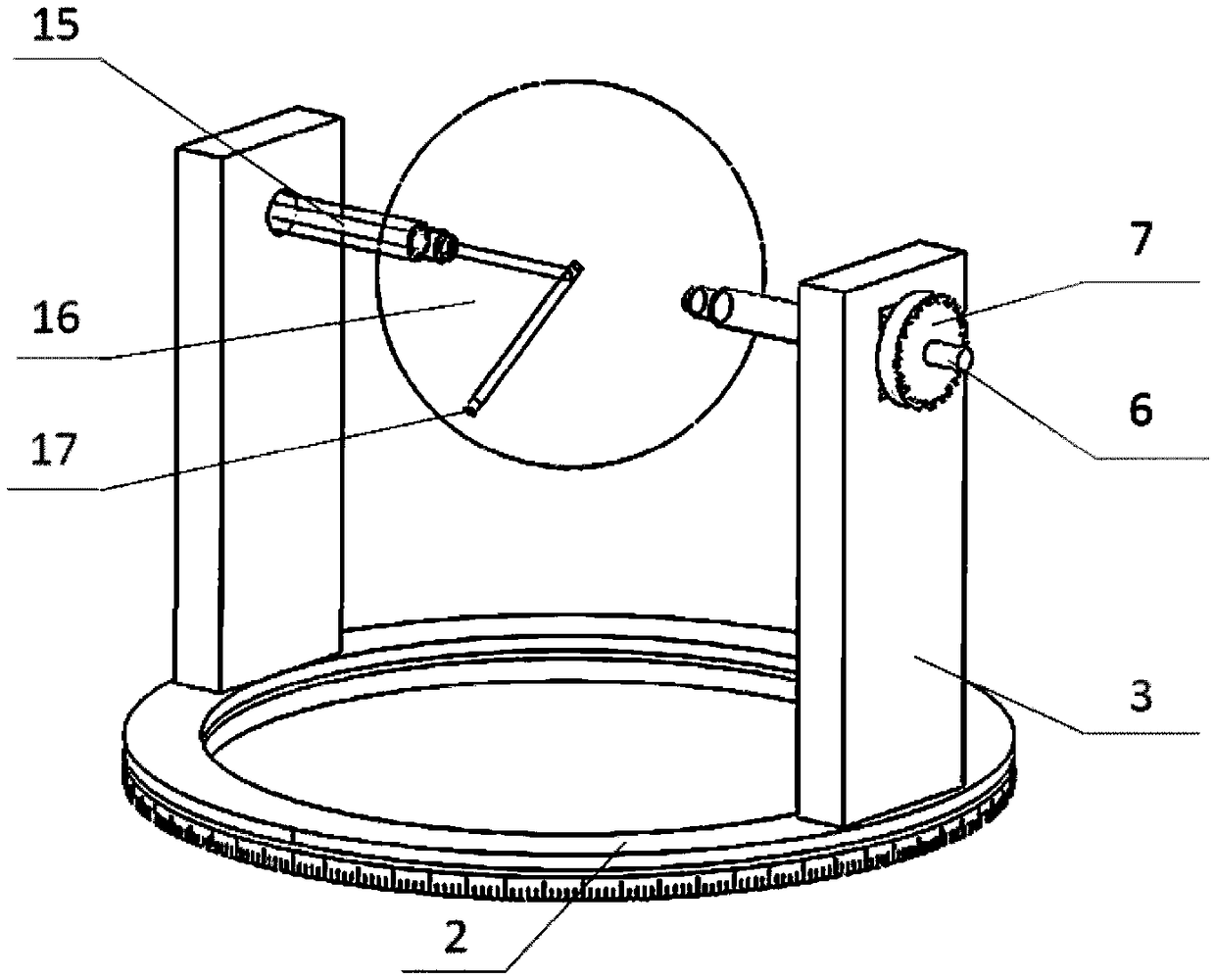

[0032] like figure 1 , 2, 3 and 4, a performance testing device for air-floating ball bearings, including a base 1, a latitudinal rotating table 2, a rotating shaft 6, a meridional rotating disk 7, a bearing capacity loading mechanism, a displacement sensor 13, a gas pressure sensor 14 and pressure guide rod 15; base 1 is the supporting platform of the whole detection device; latitudinal rotation table 2 comprises chassis and rotating disk; chassis is fixed on the base 1, and rotating disk and chassis constitute rotating pair; There are indicator lines on the turntable; the top surface of the turntable is fixed with two turntable support frames 3 that are symmetrical to the center of rotation of the turntable; two support sliders 5 and the chutes of the two turntable support frames 3 respectively form a sliding direction that is vertical The moving pair of the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com