A hydraulically loaded ball-on-disk type elastohydrodynamic friction tester

A hydraulic loading and friction technology, applied in instruments, measuring devices, mechanical devices, etc., can solve the problems of vibration of ball and disk specimens, inaccurate hydraulic loading, difficult processing, etc., to achieve safe and reliable operation, improve stability, The effect of preventing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

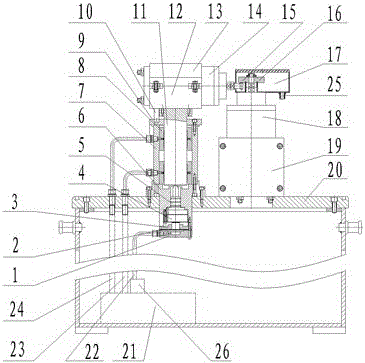

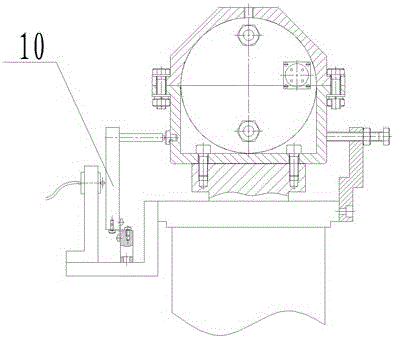

[0024] Such as figure 1 , a hydraulically loaded ball-on-disk type elastohydrodynamic friction tester of the present invention includes a box body 20, a hydrostatic shaft 11, a hydrostatic bearing 8, a hydrostatic bushing 7, an electric spindle A14, an electric spindle B18, a ball test piece 15, a disk Test piece 16, oil return pan 17, electric spindle A upper clamp seat 13, electric spindle A lower clamp seat 12, electric spindle B clamp seat 19, loading measurement system, friction measurement system 10.

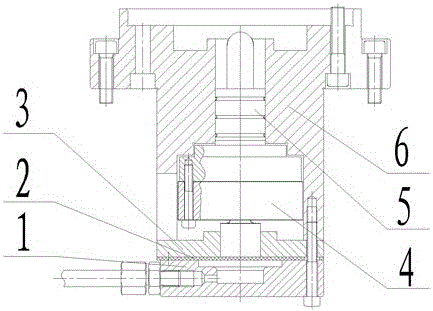

[0025] The loading measurement system includes a hydraulic station 21 , a loading oil pool 1 , a silicone pad 2 , a load sensor head cover 3 , a load sensor 4 , a loading body 5 , and a loading cover 6 . The load sensor 4 is fixedly connected with the loading body 5, the lower part of the load sensor 4 extends into the load senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com