Multi-mode degradation process modeling and residual service life prediction method

A life prediction and multi-mode technology, applied in character and pattern recognition, CAD numerical modeling, design optimization/simulation, etc., can solve problems such as difficult to obtain first arrival time distribution, unknown degradation mode switching, etc., to achieve reasonable design , the effect of good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

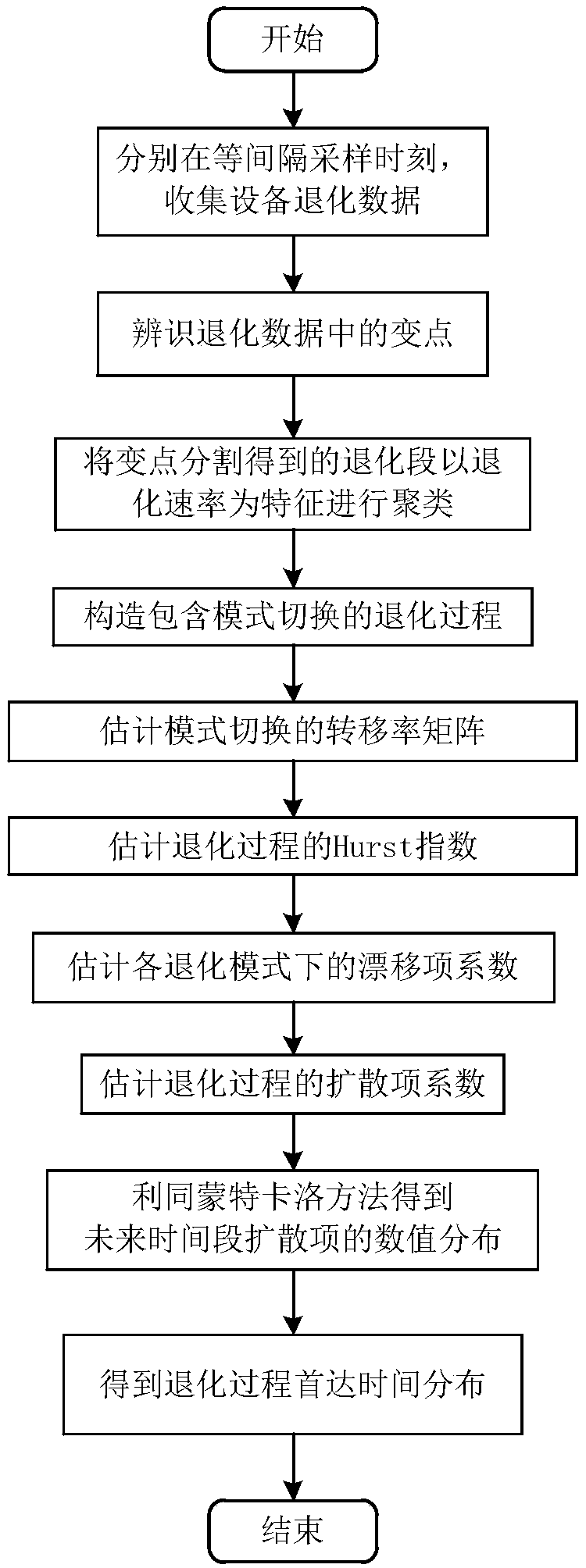

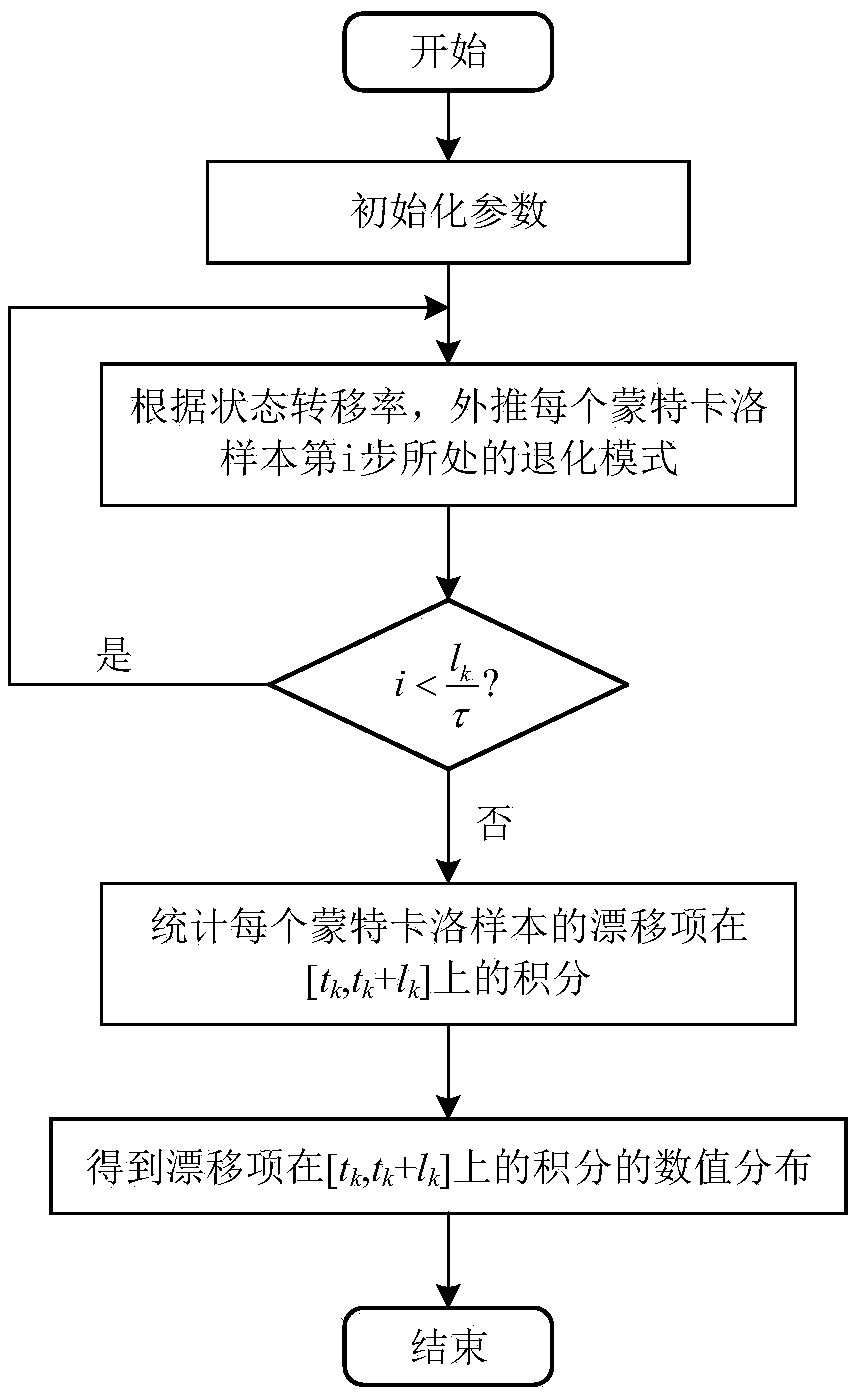

[0073] A multi-mode degradation process modeling and remaining life prediction method, the process is as follows figure 1 shown, including the following steps:

[0074] Step 1: Sampling time t at equal intervals respectively 0 ,t 1 ,t 2 ,...,t k Collect equipment degradation data x 0 ,x 1 ,x 2 ,...,x k , where the sampling interval is τ, and k is the number of samples;

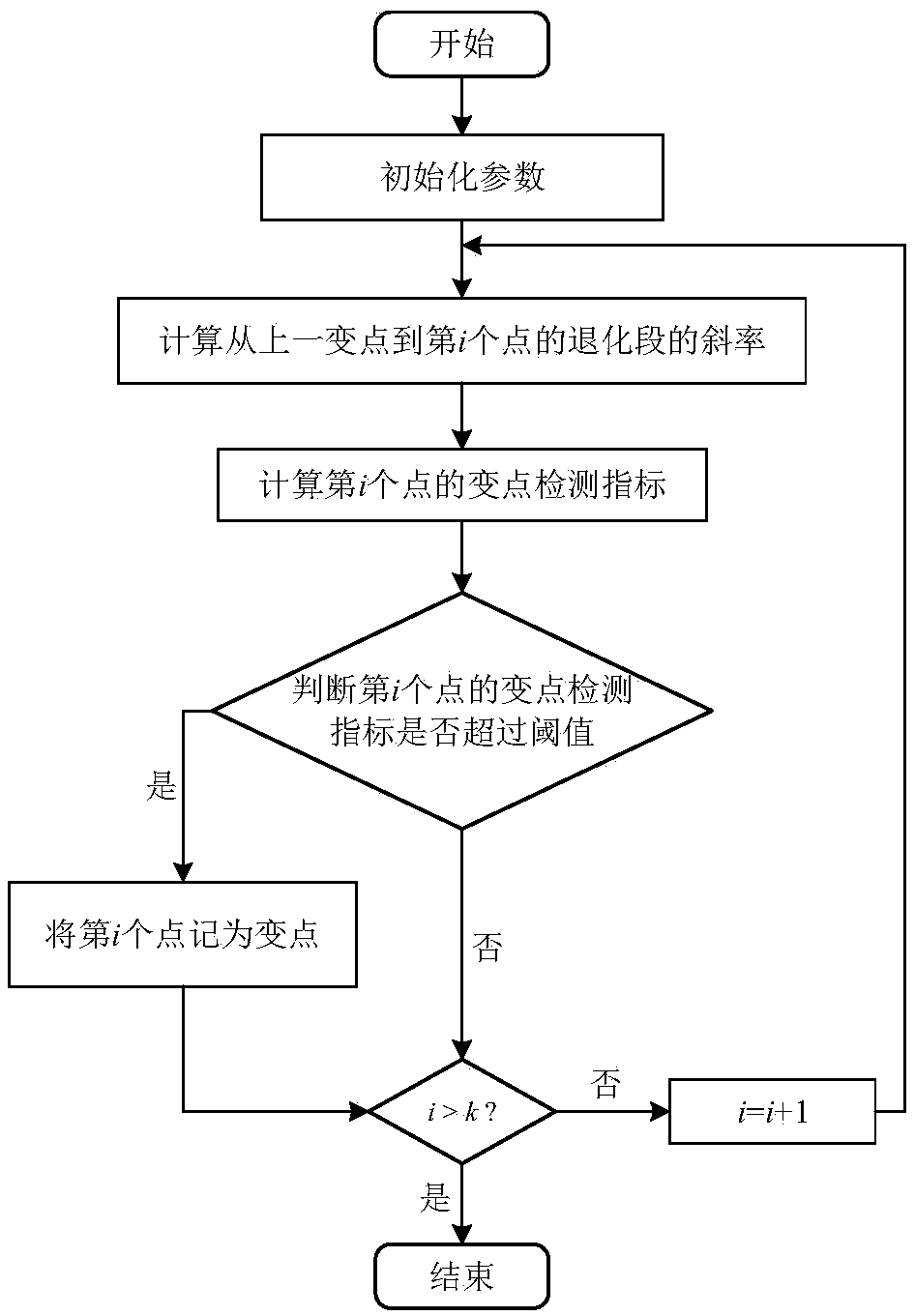

[0075] Step 2: According to the change point detection method (the process is as follows figure 2 shown), detect the slope change point of the historical degradation process, denoted as γ 1 ,γ 2 ,...;

[0076] Step 3: Take the point γ obtained in step 2 j and gamma j+1 Get the degenerate section for the endpoint, and calculate the slope of the degenerate section according to the following formula and this slope As the eigenvalue of the jth degradation segment;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com