Single-cavity sandwich-type automobile subwoofer

A sandwich type, subwoofer technology, applied in the direction of loudspeakers, electrical components, sensors, etc., to reduce weight, improve electro-acoustic conversion efficiency, and achieve the effect of pure bass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

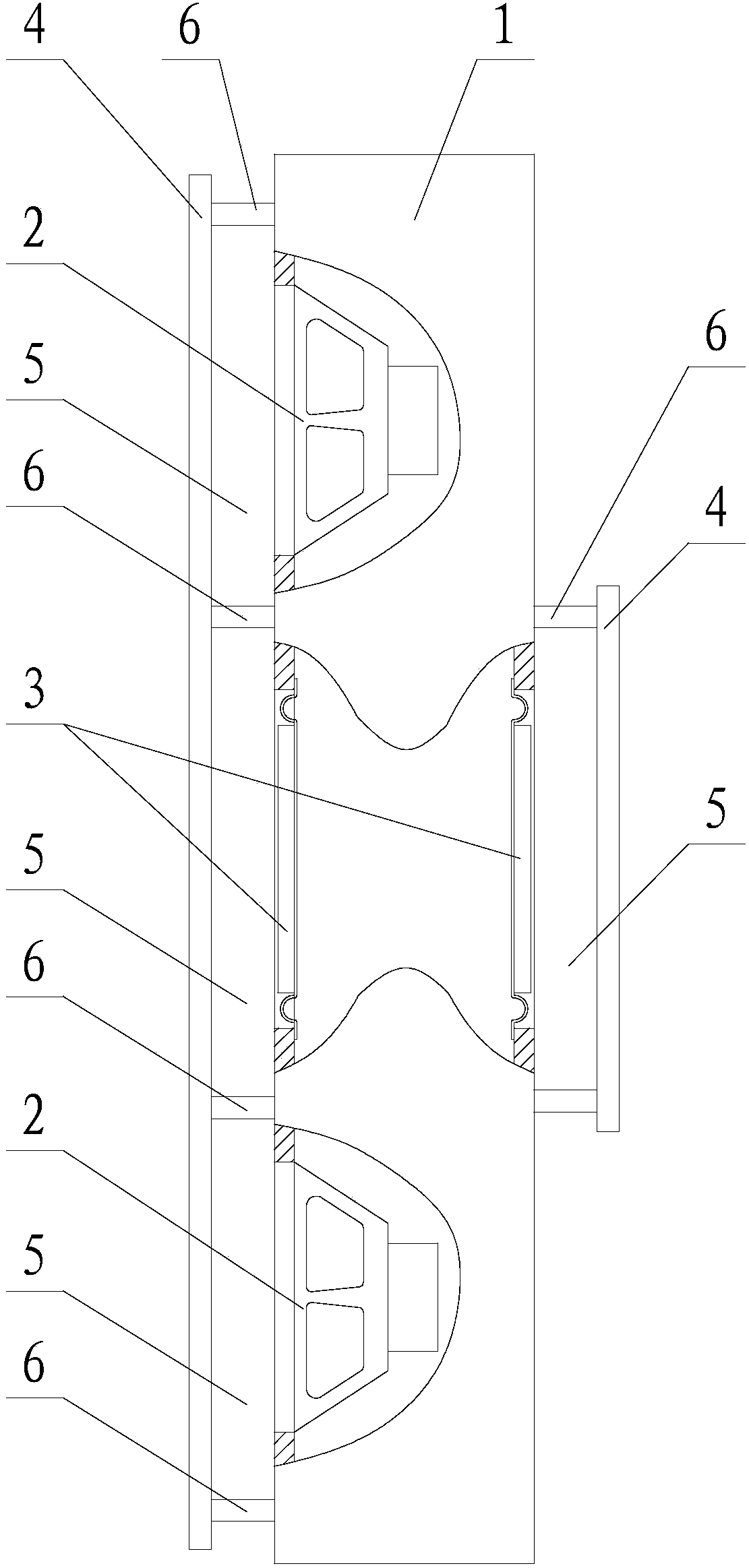

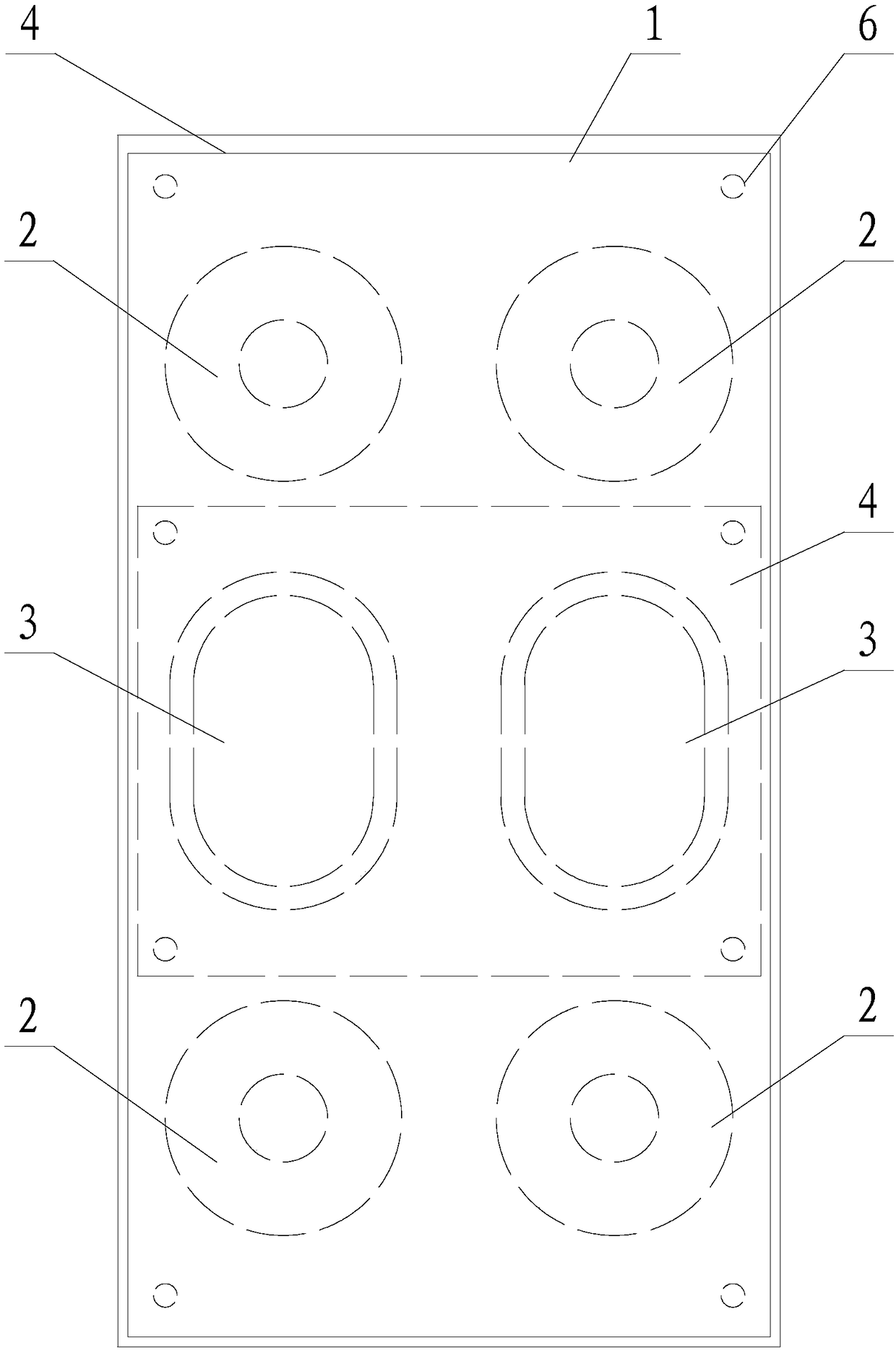

[0059] Such as Figure 1A , Figure 1B As shown, the subwoofer of the present embodiment has only a single-cavity subwoofer housing 1, which is in the shape of a cuboid, and four subwoofer speakers 2 are arranged in the subwoofer housing 1, and they are in groups of two. They are respectively symmetrically installed on the front box wall of the subwoofer body 1; the subwoofer 2 may consist of one or more subwoofer units, and each subwoofer unit may be circular or elliptical. In this embodiment, a circular woofer unit with a diameter of 92 mm is installed in each woofer 2 . Two groups of bass radiator groups 3 are also arranged in the subwoofer body 1, and each group of bass radiators 3 is composed of a pair of (2) bass radiator units, and a pair of bass radiator units in each group are arranged correspondingly before and after each other. . Bass radiators are also known as passive low-frequency radiators, also known as empty speakers, which have no magnets and voice coils, o...

Embodiment 2

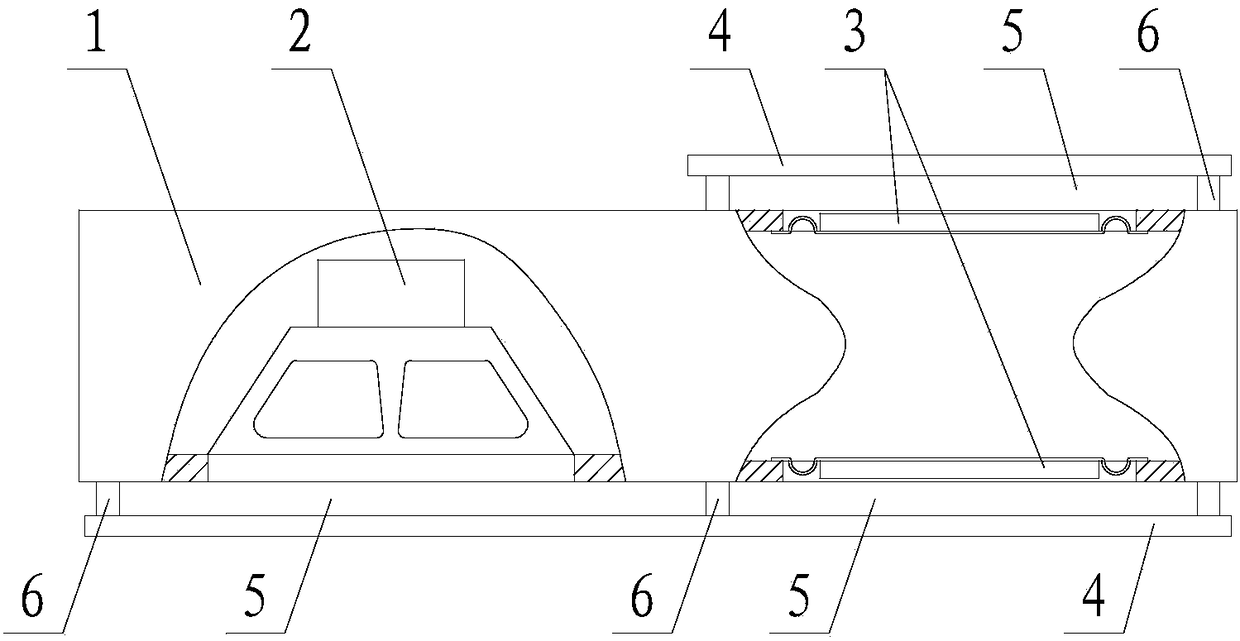

[0064] Such as Figure 2A , Figure 2B As shown, the difference between this embodiment and Embodiment 1 is: there are two woofers 2 in this embodiment, and the bass radiator group 3 is two groups of four bass radiator units, and these bass radiator units are the same Round bass radiator unit. The rest are all the same as in Example 1.

Embodiment 3

[0066] Such as Figure 3A , Figure 3B As shown, the difference between the present embodiment and the second embodiment is that there is one woofer 2 in this embodiment, and the bass radiator group 3 is a group of two bass radiator units. All the other are identical with embodiment two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com