Combined device for producing chocolate

A chocolate and equipment technology, which is applied in the field of equipment for combined production of chocolate, can solve the problems of large production volume, high labor intensity, and many processes.

Inactive Publication Date: 2018-10-12

晋江市隆兴食品有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] With the passage of time, the population is also increasing, and the demand for all walks of life is very large. For the production of chocolate, because chocolate is sweeter, many people prefer it, so for factories The production volume is relatively large. In the traditional production, although there is a chocolate discharge device, it is also necessary to manually hold the mold to undertake the molding, which is relatively troublesome. If mass production, manual The strength is relatively high, and the efficiency is not high. Since chocolate is food, the more artificial contact there is, the more bacteria will be brought by artificially. Some chocolate needs to be decorated with food grade on the surface after molding. It is manually placed, and there are many processes, which is relatively troublesome. It also needs to be refrigerated during molding. Traditional tools are not suitable for assembly line production. Therefore, in order to solve these problems and better meet people's needs, a A combination of equipment for producing chocolate is necessary

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

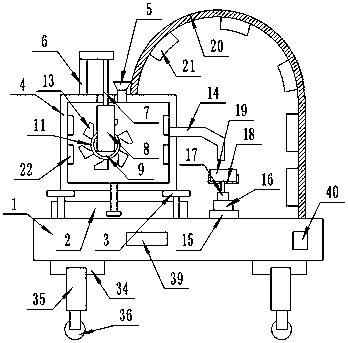

[0026] Embodiment 2: The hydraulic push rod 7 can be replaced by a telescopic cylinder, which can also achieve the telescopic effect, and other structures are the same as in Embodiment 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

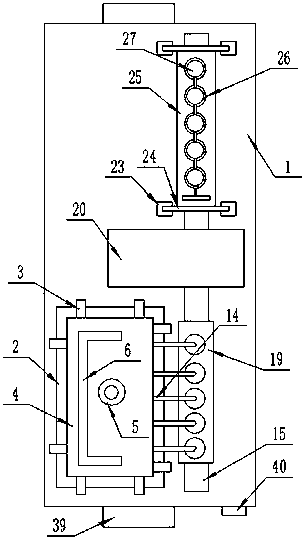

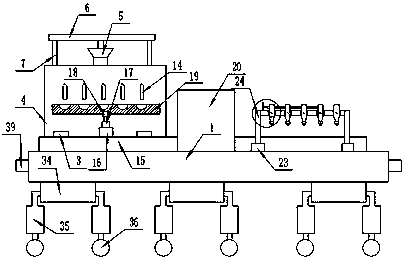

The present invention discloses a combined device for producing chocolate. The device comprises a strip-shaped bearing base; a chocolate forming mechanism is arranged on the upper surface of the strip-shaped bearing base; a combined production mechanism is arranged on the upper surface of the strip-shaped bearing base and positioned on the right side of the chocolate forming mechanism; and a supporting and moving mechanism is arranged on the lower surface of the strip-shaped bearing base. The beneficial effects of the invention are that the device is convenient to use, convenient to stirring raw materials uniformly, good in forming and convenient to placing other foods on the device, reduces manual contact, is convenient for continuous work, and improves the working efficiency.

Description

technical field [0001] The invention relates to the field of chocolate production, in particular to a combined chocolate production equipment. Background technique [0002] Chocolate production equipment is the equipment for making raw chocolate into shapes, and combined production is the operation of placing other foods on the surface of the original chocolate. [0003] With the passage of time, the population is also increasing, and the demand for all walks of life is very large. For the production of chocolate, because chocolate is sweeter, many people prefer it, so for factories The production volume is relatively large. In the traditional production, although there is a chocolate discharge device, it is also necessary to manually hold the mold to undertake the molding, which is relatively troublesome. If mass production, manual The strength is relatively high, and the efficiency is not high. Since chocolate is food, the more artificial contact there is, the more bacter...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A23G1/04A23G1/10A23G1/54

CPCA23G1/045A23G1/105A23G1/54

Inventor 陈建军

Owner 晋江市隆兴食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com