Adjustable jet device

An injector and adjustable technology, applied in the field of injectors, can solve the problems of inability to adjust, poor real-time performance, inconvenient operation, etc., and achieve the effect of increasing the sealing effect and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

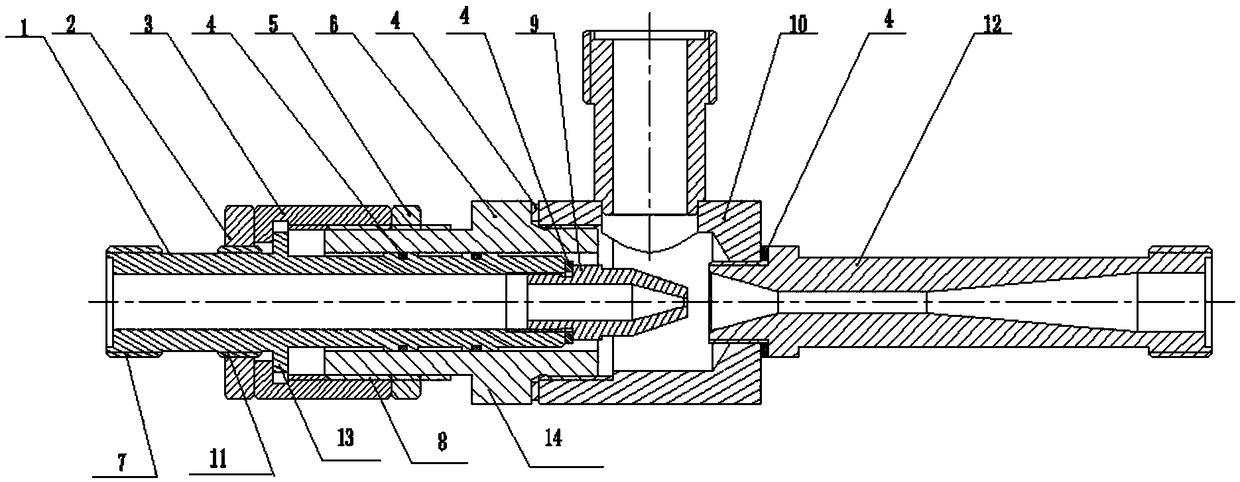

[0029] An adjustable jet, which includes a spray head 1, a long joint 6, a jet nozzle 9, a water absorption chamber weldment 10 and a mixing tube 12 that is threadedly connected to the front end of the water absorption chamber weldment, and the jet nozzle is set on the front end of the inner diameter of the spray head The long joint is set on the outer diameter of the nozzle, the rear part of the welded part of the water absorption chamber is connected to the front part of the long joint through threads, and the long joint that is fixedly connected with the nozzle is installed on the outer diameter of the rear of the long joint. Nut 3, the long connecting nut is provided with a front locking device and a rear locking device.

[0030] Further, the outer diameter of the rear part of the long joint is provided with a long joint external thread 8, and the long union nut is sleeved on the long joint external thread.

[0031] Further, the rear locking device includes an external thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com