Method for rectification of large plate-shaped structural members

A technology for structural parts and large plates, applied in the field of correction of large plate-shaped structural parts, can solve problems such as low processing efficiency and inapplicability, and achieve the effects of reducing energy consumption, avoiding rework and improving correction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

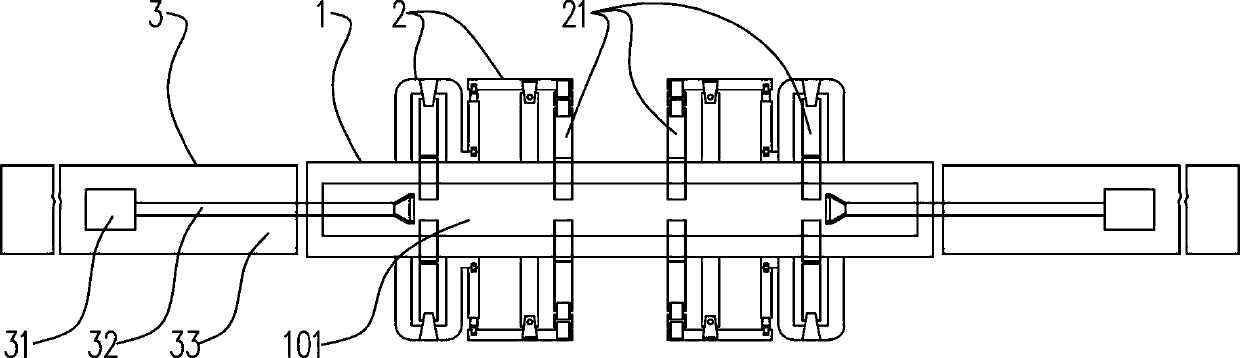

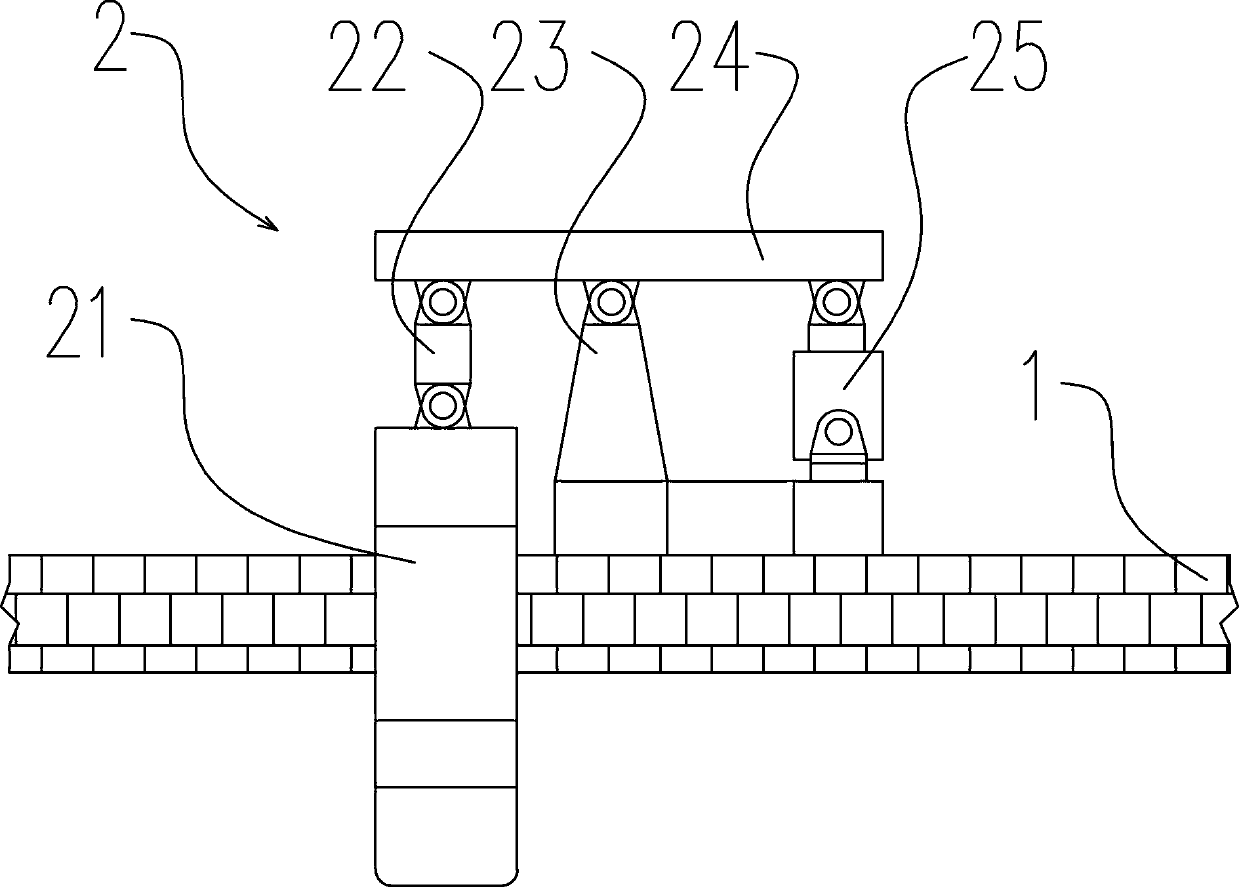

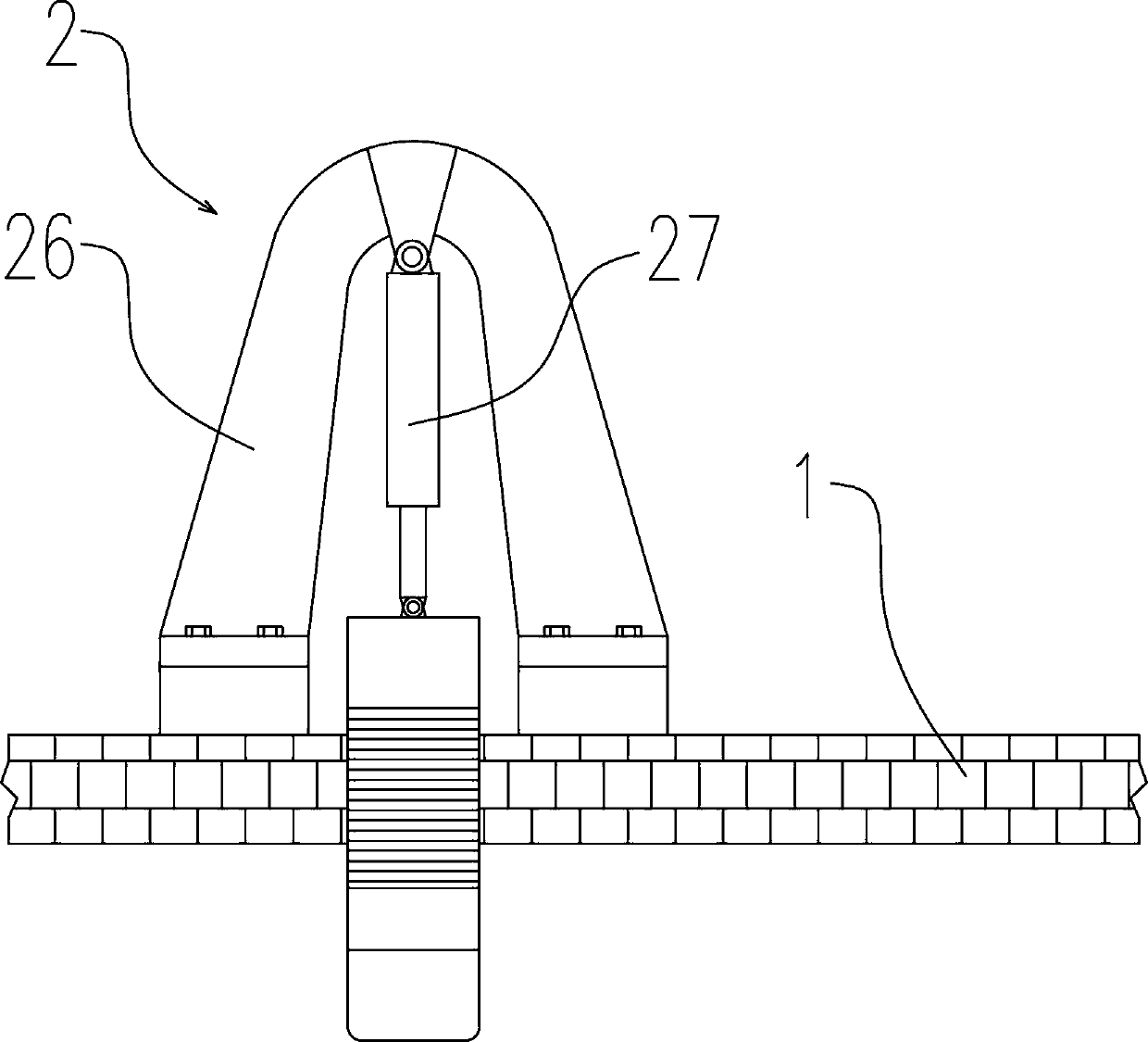

[0049] Such as figure 1 , 5 , 8~10, and 13, a method for rectifying a large plate-shaped structural member, comprising the following steps:

[0050] s1. A plurality of indenter devices 2 are arranged on both sides of the furnace body 1, and the plurality of indenter devices 2 can correct the plate-shaped structural member 5 vertically fixed along the degree direction by means of overcorrection. Flat, in order to facilitate the processing of subsequent processes. The furnace body 1 adopts the structure of a tunnel kiln, and the temperature in the furnace is usually 500 ° C ~ 750 ° C. At least one end of the furnace body 1 is provided with a pushing device 3 . In a preferred solution, both ends of the furnace body 1 are equipped with a pushing device 3 . An observation window 101 is provided on the top of the body of heater 1, and an acquisition device 6 is arranged above the observation window 101. An image acquisition head, such as a video camera, is provided in the acquisit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com