Thermal management method and thermal management device of power lithium ion battery system

A lithium-ion battery and thermal management technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve problems such as limited charging, reduced battery life, increased battery temperature, etc., to achieve space utilization Maximize, reduce potential safety hazards, save energy and increase the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In view of the deficiencies in the prior art, the inventor of this case has been able to propose the technical solution of the present invention after long-term research and extensive practice. The technical solution, its implementation process and principles will be further explained as follows.

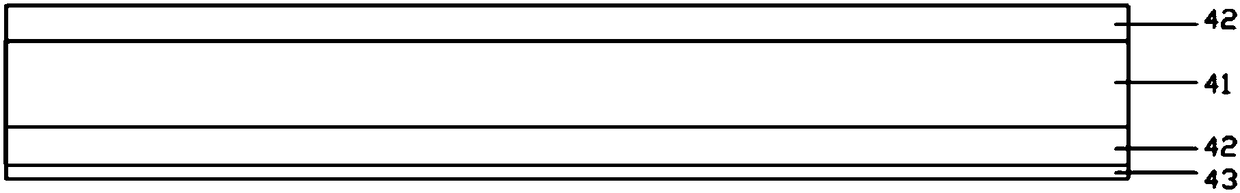

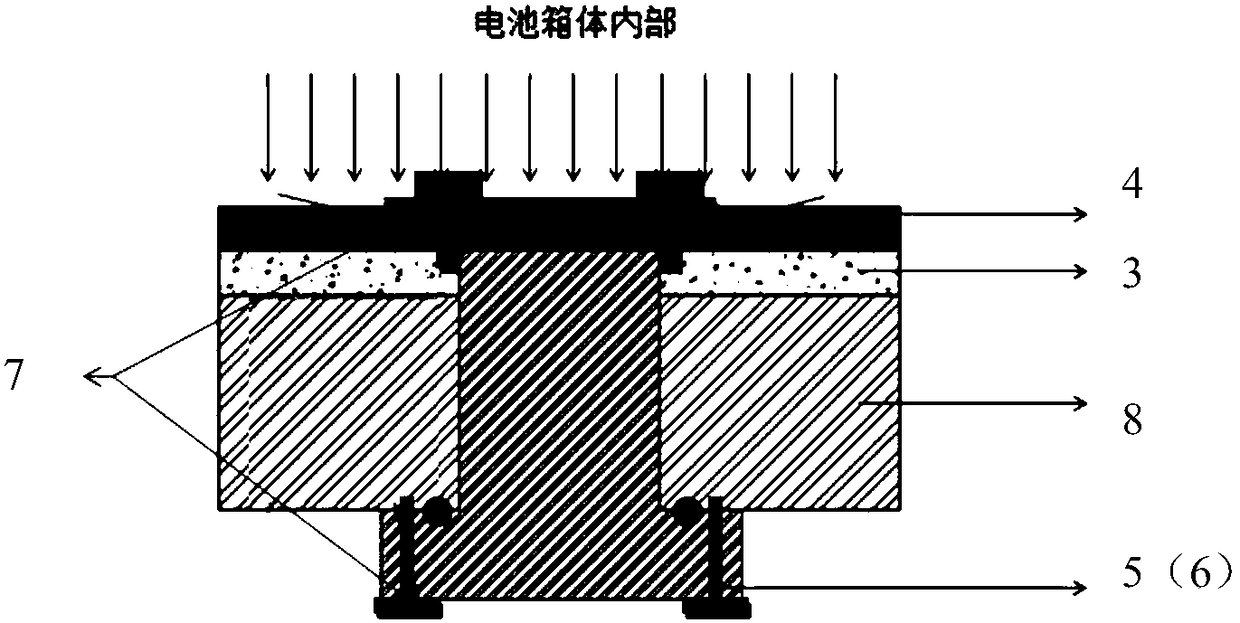

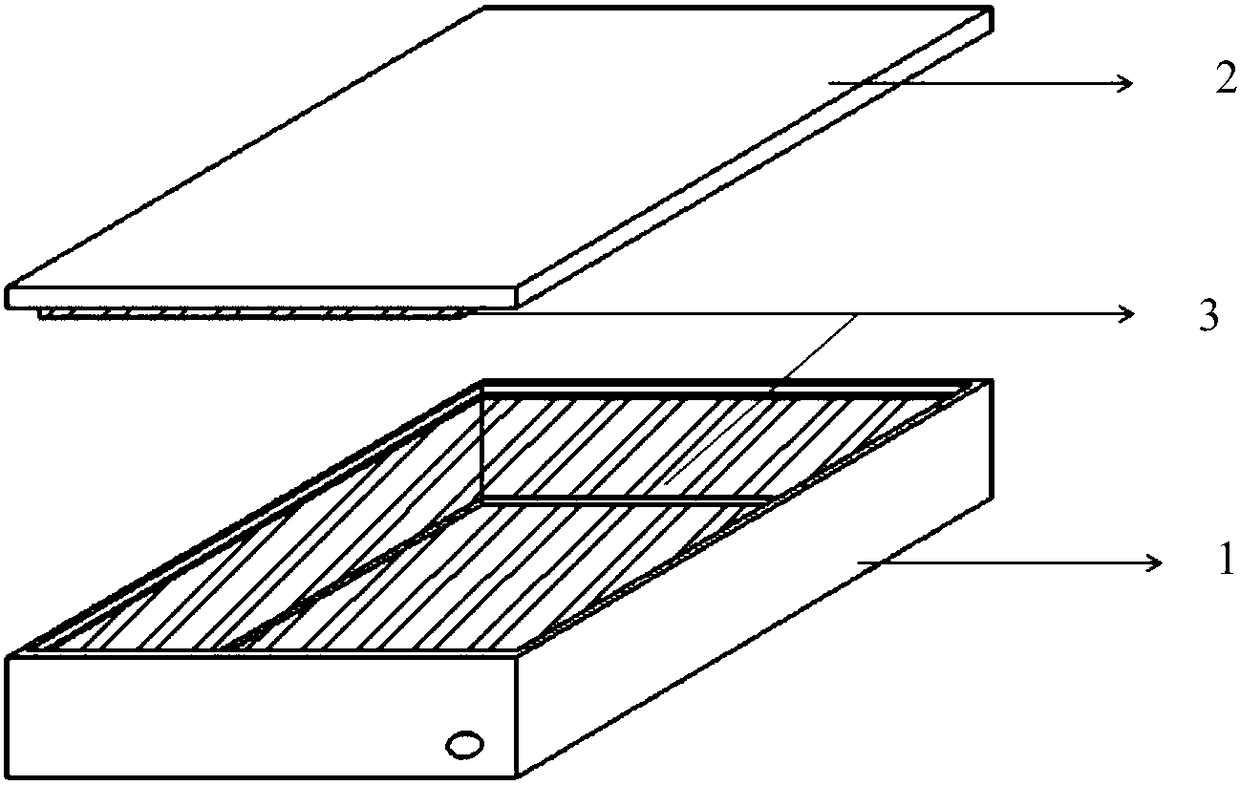

[0016] An embodiment of the present invention provides a thermal management method for a power lithium-ion battery system, including: placing at least a portion of a heat-conducting film in at least a selected area of the inner cavity of a lithium battery box, and the selected area houses a The power lithium battery pack is above, and the at least one heat conduction film is thermally connected to the cooling and / or heating device placed outside the lithium battery box.

[0017] Further, the thermal management method includes: placing at least one heat conduction film in a selected area of the inner cavity of the lithium battery box, and connecting the at least one heat co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com