Method for checking levelness of straightening rollers of steel cold straightener

A technology of straightening rolls and cold straightening, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems that the level data cannot be directly displayed, the adjustment value cannot be obtained, and it is not suitable for straightening rolls, etc., to achieve good economy Benefits and social benefits, easy operation, and the effect of reducing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The calibration level of the straightening machine is an important production link in the assembly of the straightening machine and the calibration of mechanical parameters before production. The data, that is, the accuracy of the basic positioning of each roll, directly affects the accuracy of the straightening machine, thereby affecting the steel. The precision output and quality of each piece of product.

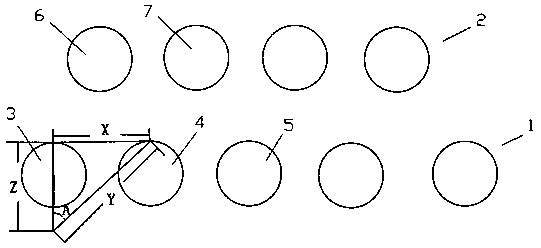

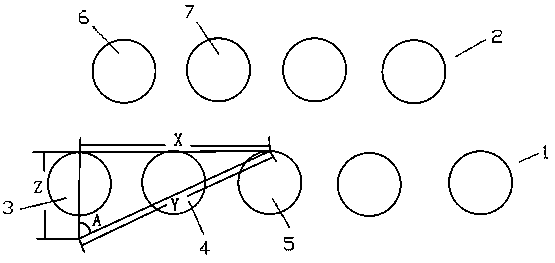

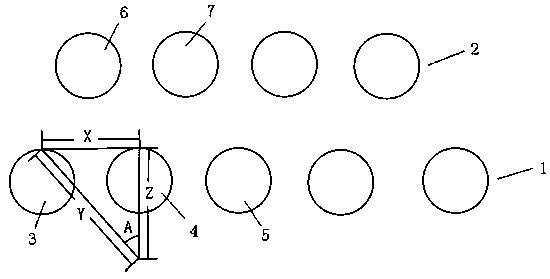

[0025] The adjustment of the straightening rollers of the cold leveling machine is divided into pitch, vertical and axial adjustments. During the construction or overhaul of the straightening machine, it is necessary to check the horizontal plane of several straightening rollers, and give the vertical and axial adjustments. The reference calibration surface for adjustment, while the axial adjustment is the same as the vertical, only the direction rotation force is 90 degrees, and the calibration method is basically the same.

[0026] The following uses vertical adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com