Mold splitting material taking device for optical mold

A technology of reclaiming device and mould, applied in the direction of manufacturing tools, instruments, manipulators, etc., can solve the problems of inaccurate positioning of optical finished products, single movement trajectory, damage of optical finished products, etc., and achieves rapid action, flexible change, and short response time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

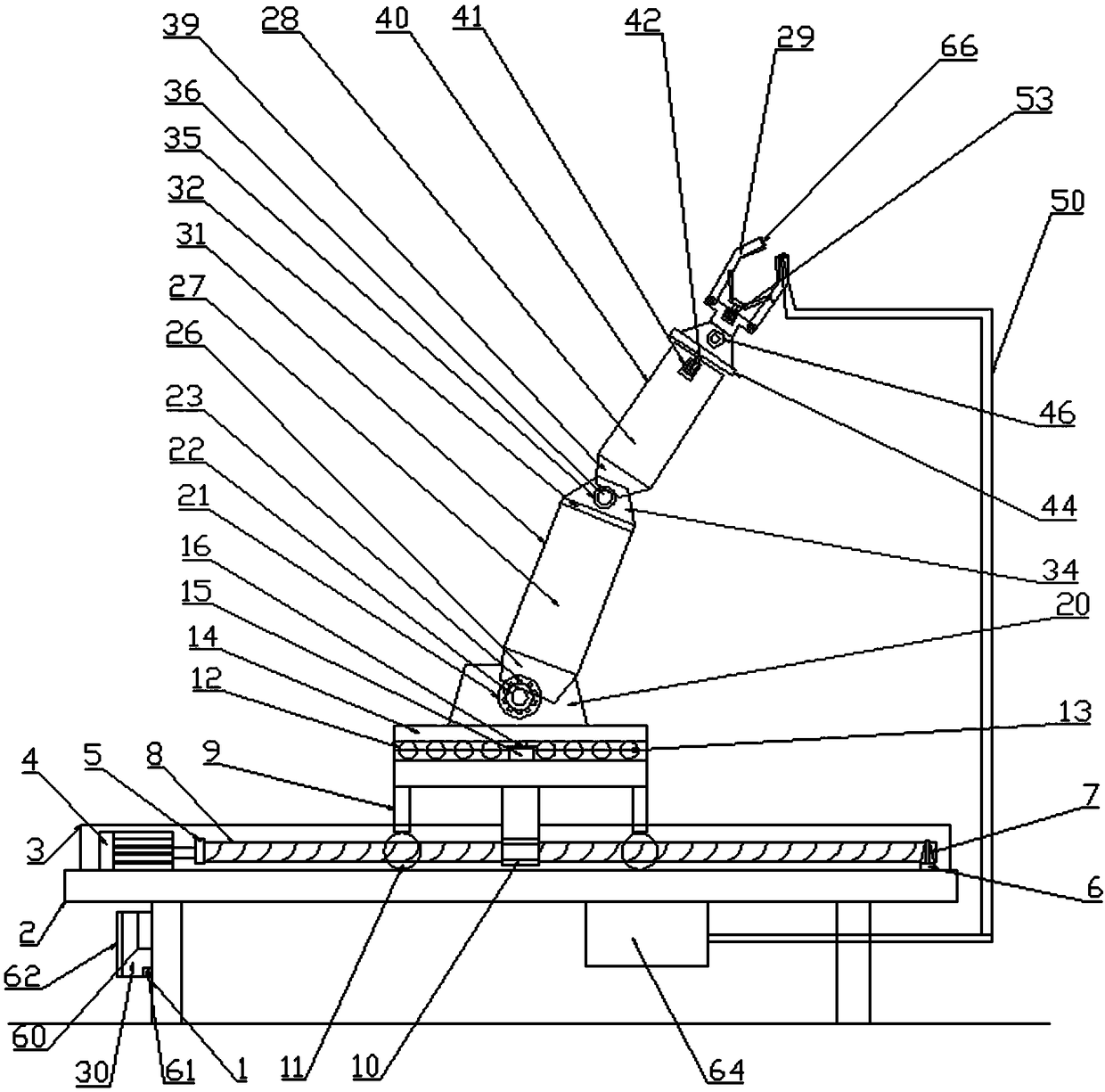

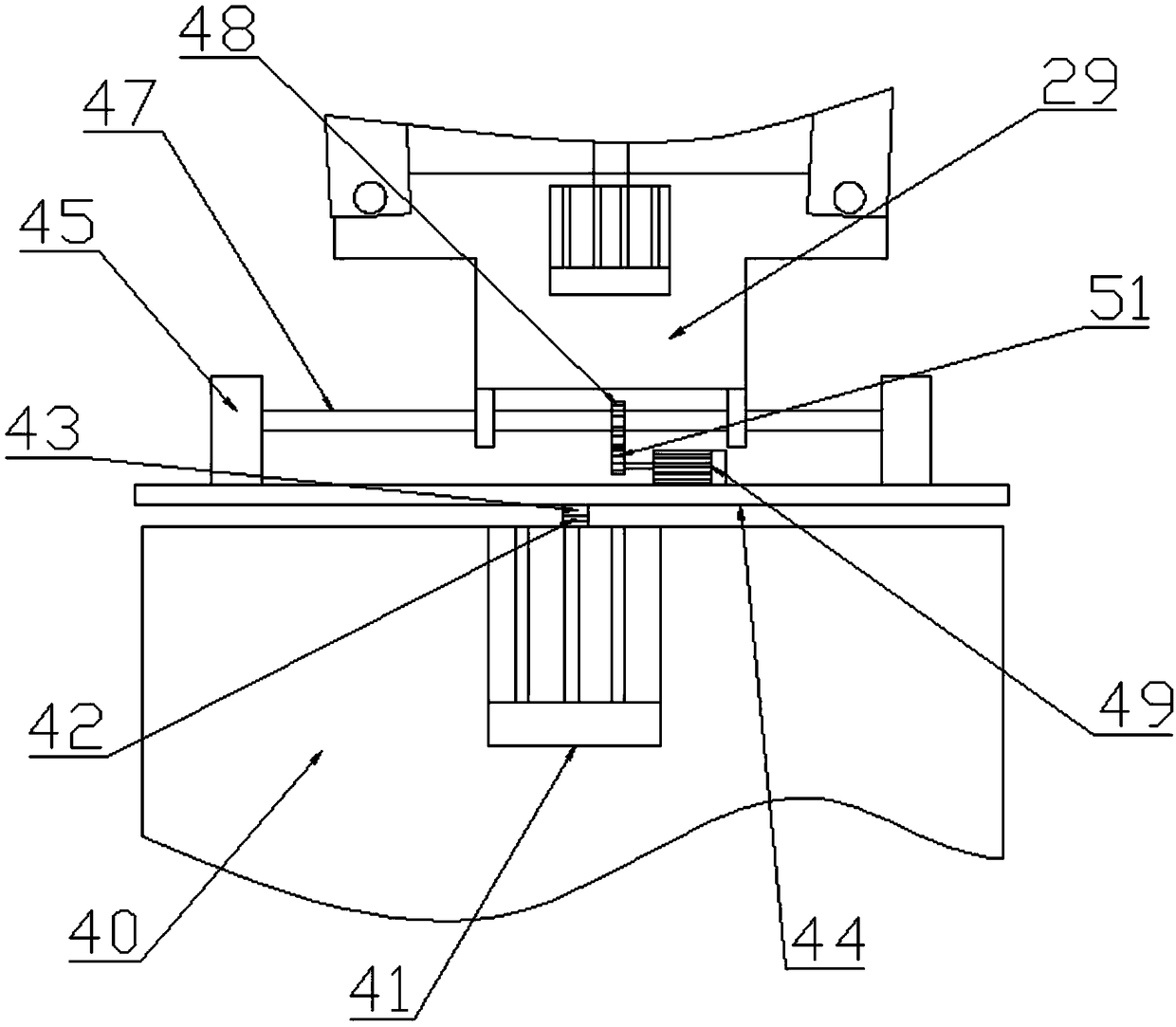

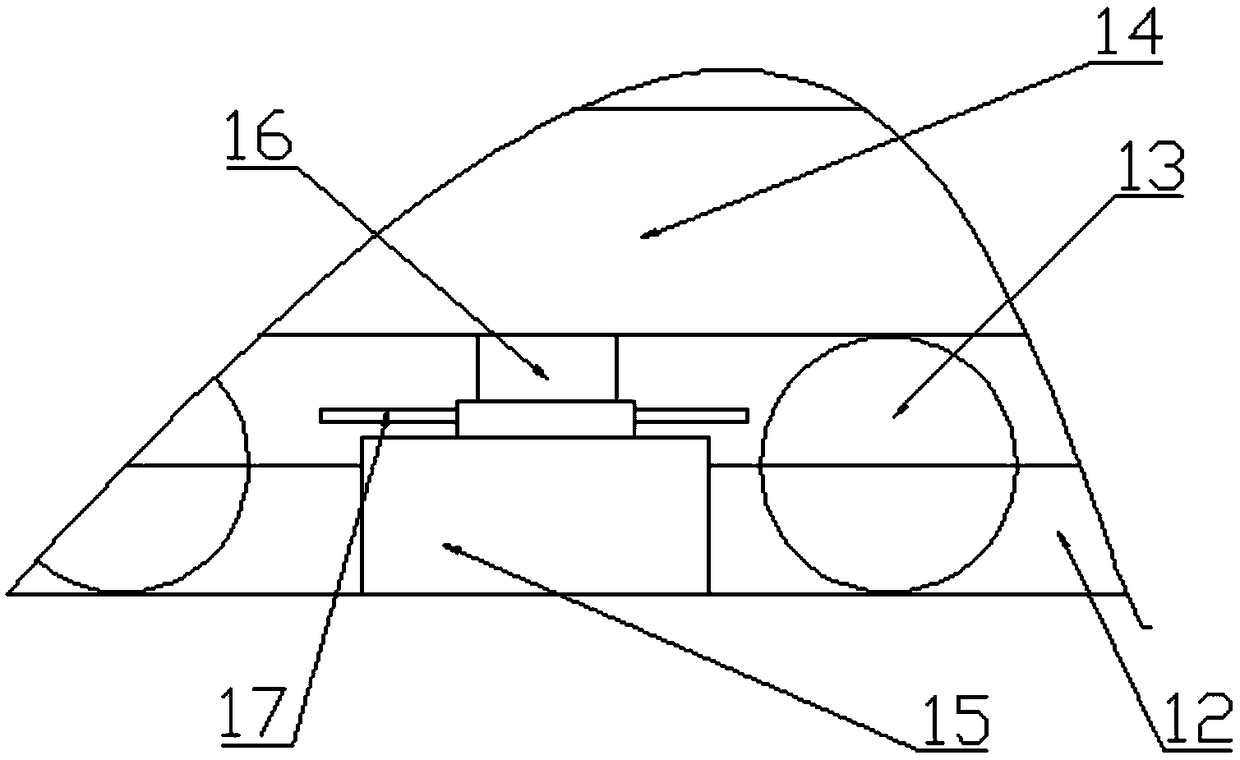

[0023] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-7As shown, an optical mold splitting and taking-out device includes a bracket-1, and the bracket-1 is fixedly installed on the ground. The bracket-1 is provided with a base moving mechanism, and the base moving mechanism is fixedly installed on the bracket - Loading plate 2 on 1, two linear guide rails fixedly installed on the upper surface of the bearing plate 2 3, a stepping motor fixedly installed on one end of the upper surface of the bearing plate 2 and located in the middle of the two linear guide rails 3 - 4, fixed installation Coupling-5 at the output end of stepping motor-4, fixedly installed on the bearing plate 2 and screw seat 6 opposite to stepping motor-4, screw bearing 7 fixedly installed on the screw seat 6, one end The screw 8 fixedly installed on the coupling 5 and the other end fixedly installed on the screw bearing 7, the screw mounting seat 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com