A hot stamping die-cutting machine

A technology of cutting machines and gold molds, which is applied to printing machines, gold powder printing, rotary printing machines, etc., can solve problems such as safety accidents, affect production efficiency, and increase labor intensity of staff, so as to avoid safety accidents, reduce labor costs, The effect of improving work efficiency

Active Publication Date: 2019-11-08

安徽省瑞尔印务有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the production quality and production efficiency are related to the proficiency of the operator, it not only affects the production efficiency, but also greatly increases the labor intensity of the staff, and it is easy to cause safety accidents when feeding and receiving paper manually

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

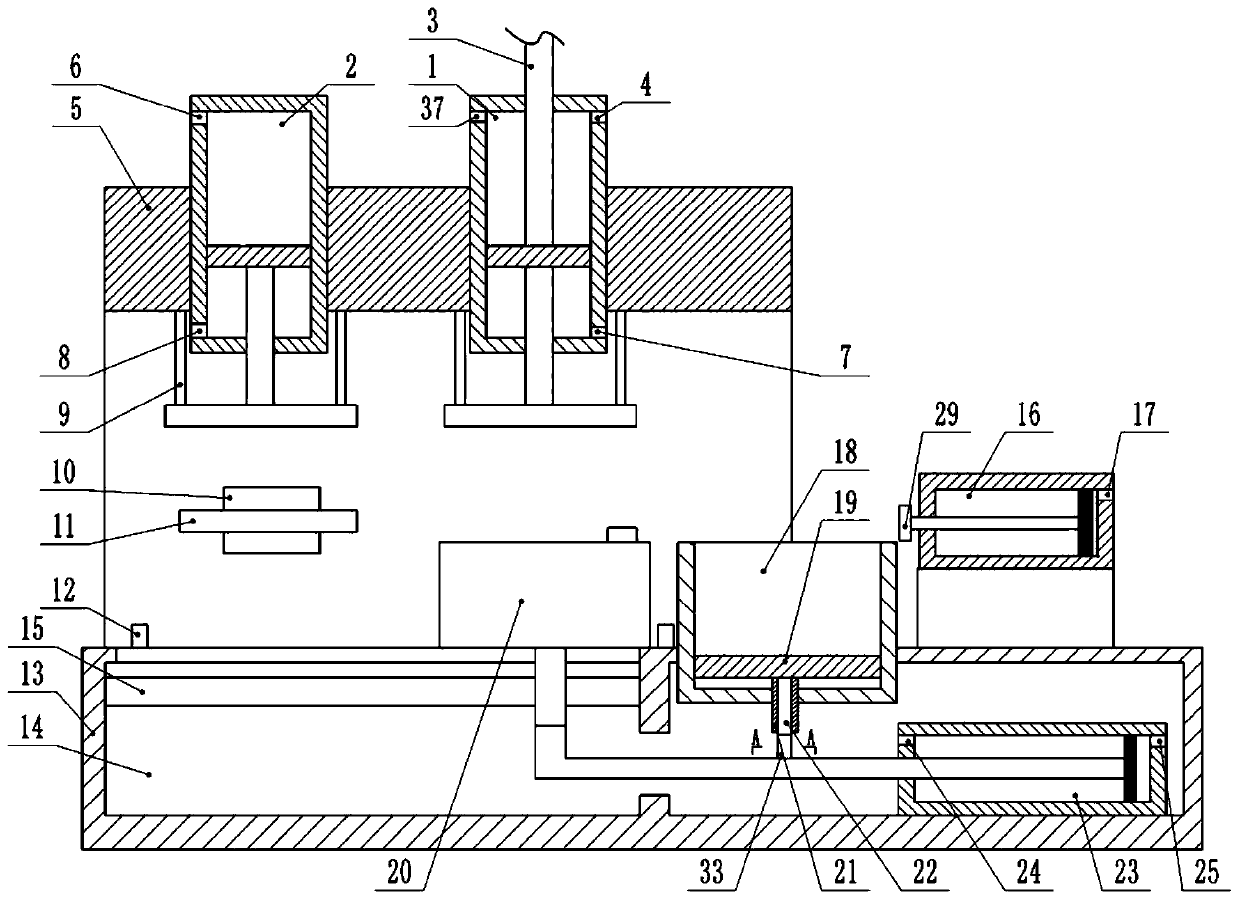

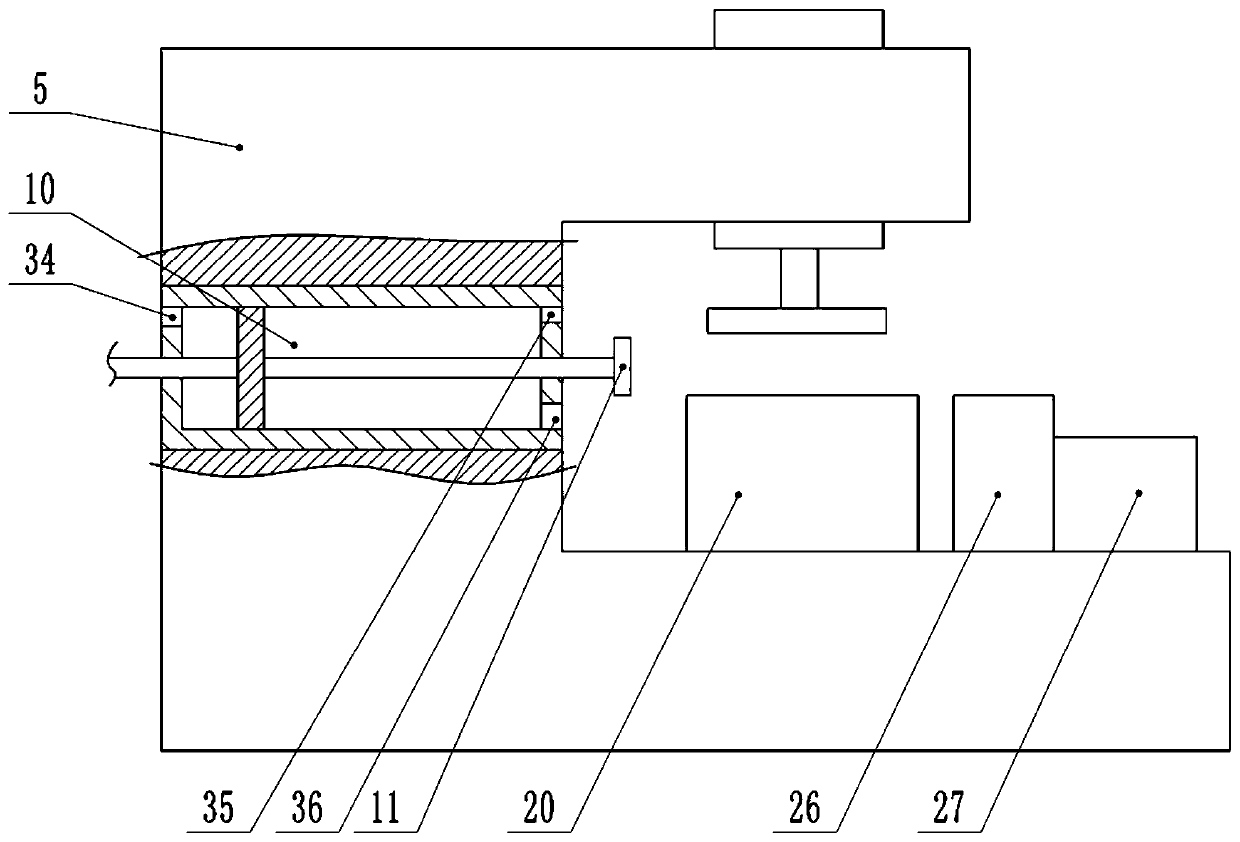

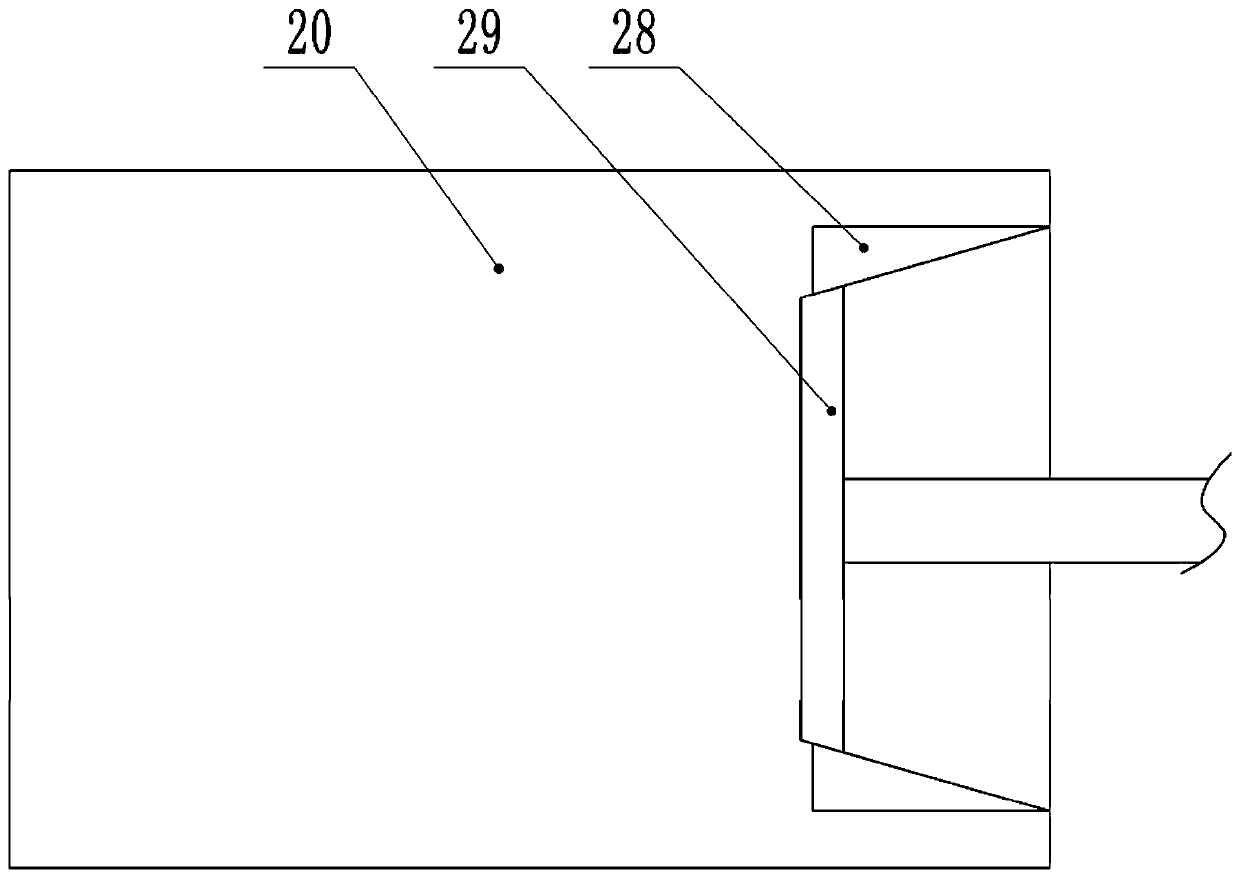

The invention belongs to the technical field of printing equipment, and particularly discloses a gold stamping die cutting machine. The gold stamping die cutting machine comprises a gold stamping aircylinder, a cutting air cylinder and a feeding mechanism; a discharging mechanism is arranged below the cutting air cylinder, the lower portion of the gold stamping air cylinder is in sliding connection with a bearing plate, a conveying air cylinder is arranged below the bearing plate, a piston rod of the conveying air cylinder is fixedly connected with the bearing plate, the feeding mechanism comprises a material box, a lifting table is arranged in the material box, and a one-way ascending mechanism is arranged between the lifting table and the piston rod of the conveying air cylinder; a feeding air cylinder is arranged on the right side of the material box, a rodless cavity of the feeding air cylinder communicates with a rod cavity of the gold stamping air cylinder, and a rodless cavityof the conveying air cylinder communicates with a rodless cavity of the gold stamping air cylinder. The discharging mechanism comprises a discharging air cylinder, a rodless cavity of the cutting aircylinder communicates with a rod cavity of the conveying air cylinder, and a rod cavity of the cutting air cylinder communicates with a rod cavity of the discharging air cylinder. A power source is further included, a pressure valve is arranged on the side wall of the gold stamping air cylinder, and the piston rod of the conveying air cylinder is a telescopic rod. Automatic feeding and dischargingof the gold stamping die cutting machine can be achieved through the scheme.

Description

technical field [0001] The invention belongs to the technical field of printing equipment, and in particular relates to a bronzing die-cutting machine. Background technique [0002] In the production process of packaging cardboard for alcohol, food, pharmaceuticals, etc., it is necessary to perform automatic stamping, die-cutting and other processes on the packaging cardboard. However, in the existing machines, the automatic hot stamping and die-cutting processes are carried out separately, that is, the automatic hot stamping machine is used for hot stamping, and then the die-cutting machine is used for die-cutting, which not only increases the input cost of equipment, but also increases the cost of production. working hours. Paper feeding and paper delivery are required in both hot stamping and die-cutting processes, while the paper feeding and paper delivery of existing die-cutting machines and hot stamping equipment is done manually. Since the production quality and pro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B41F19/06B41F19/00B41G1/02

CPCB41F19/008B41F19/06B41G1/02

Inventor 林礼区

Owner 安徽省瑞尔印务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com