Mechanical logistics feeder capable of stacking and feeding goods at different heights

A technology for goods and machinery, applied in the field of mechanical logistics feeders, can solve the problems of people inconvenience and inability to transport goods to the carriage, and achieve the effects of easy stacking, manpower saving and great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

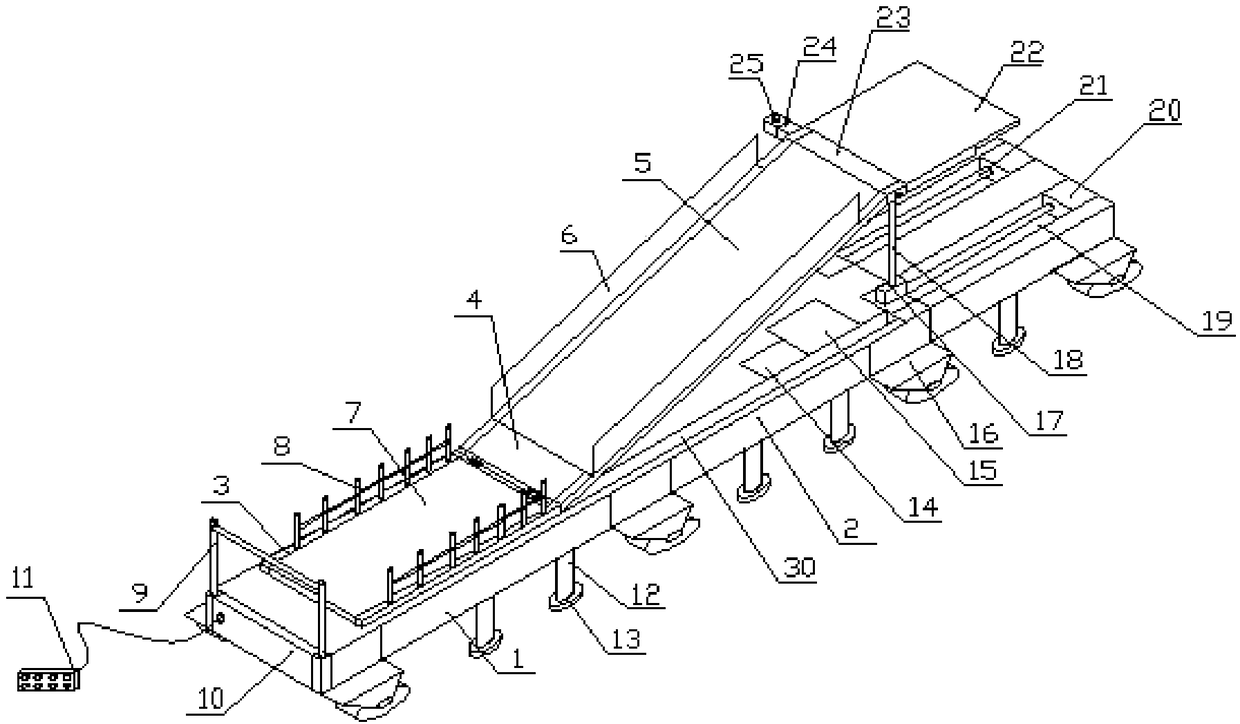

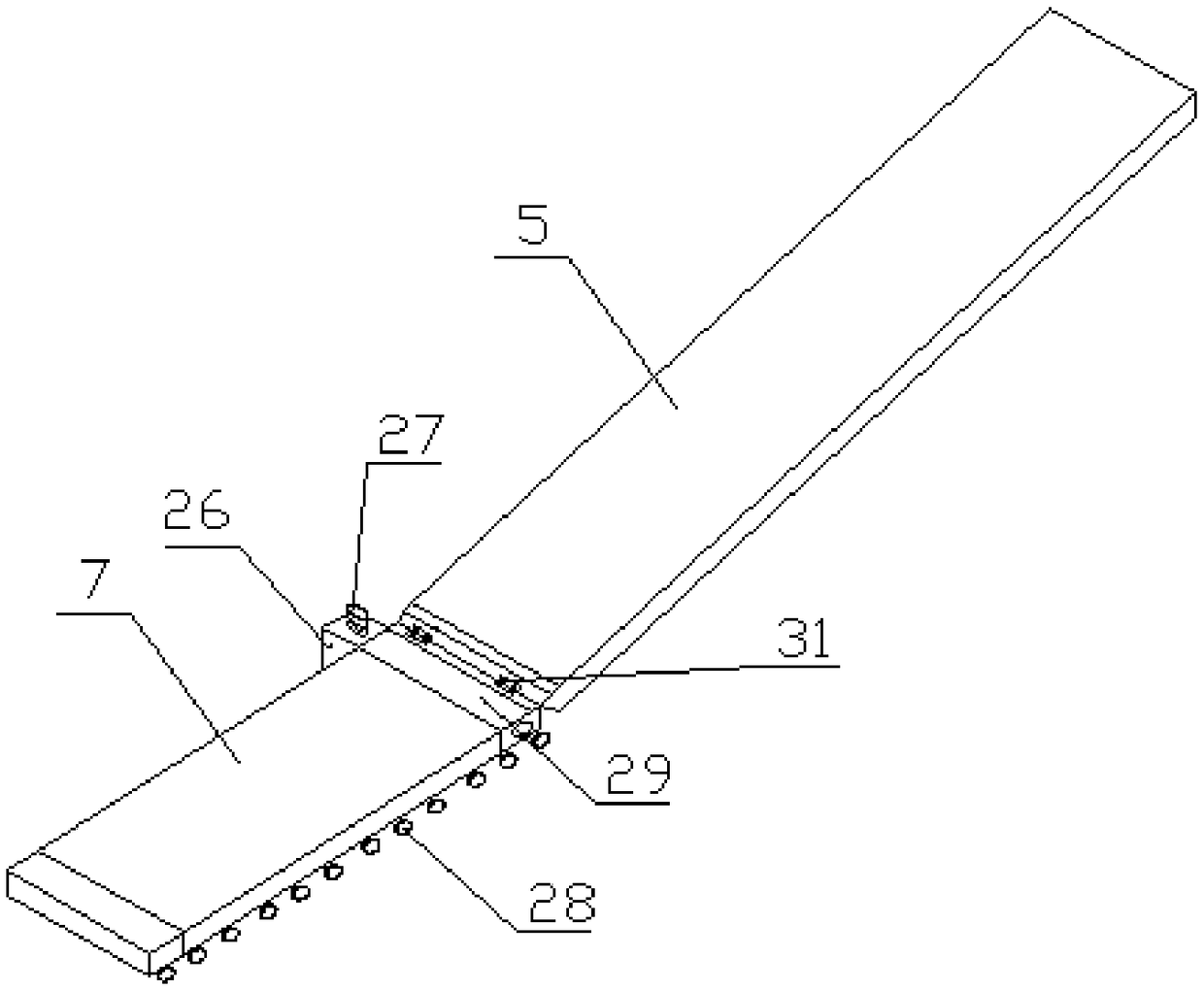

[0019] Such as Figure 1-2 As shown, the present invention provides a mechanical logistics feeder capable of stacking and loading goods of different heights, including a feeder body 1, a base 2, a storage plate 3, a connecting plate 4, a second conveyor belt 5, a stop Material plate 6, first conveyor belt 7, guardrail 8, handrail 9, brake box 10, power control board 11, hydraulic rod 12, rubber pad 13, hydraulic pump 14, hydraulic oil tank 15, roller 16, piston seat 17, second Electric telescopic rod 18, piston groove 19, first electric telescopic rod 20, connecting rod 21, material plate 22, first roller box 23, first gear box 24, first motor box 25, second gear box 26, The second motor box 27, the ball 28, the second roller box 29, the ball groove 30 and the hinge 31, the bottom end of the feeding machine body 1 is provided with a base 2, and the bottom end of the base 2 is provided with a roller 16 and a hydraulic rod 12, The bottom end of the hydraulic rod 12 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com