Buffering device for limiting

A buffer device and position-limiting technology, which is applied in the field of position-limiting buffer devices, can solve problems such as poor vibration reduction and isolation effects, and inability to effectively block vibration transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

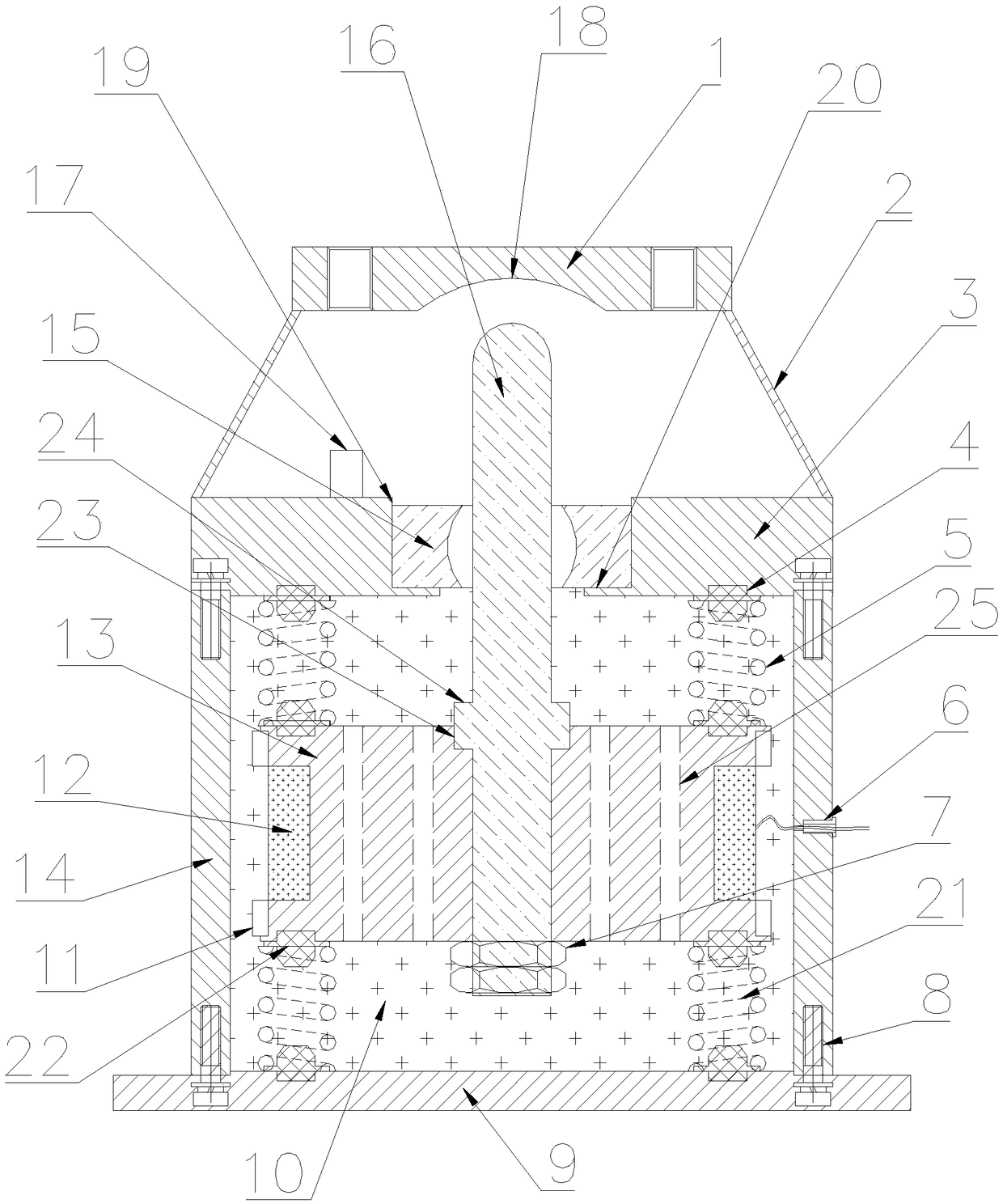

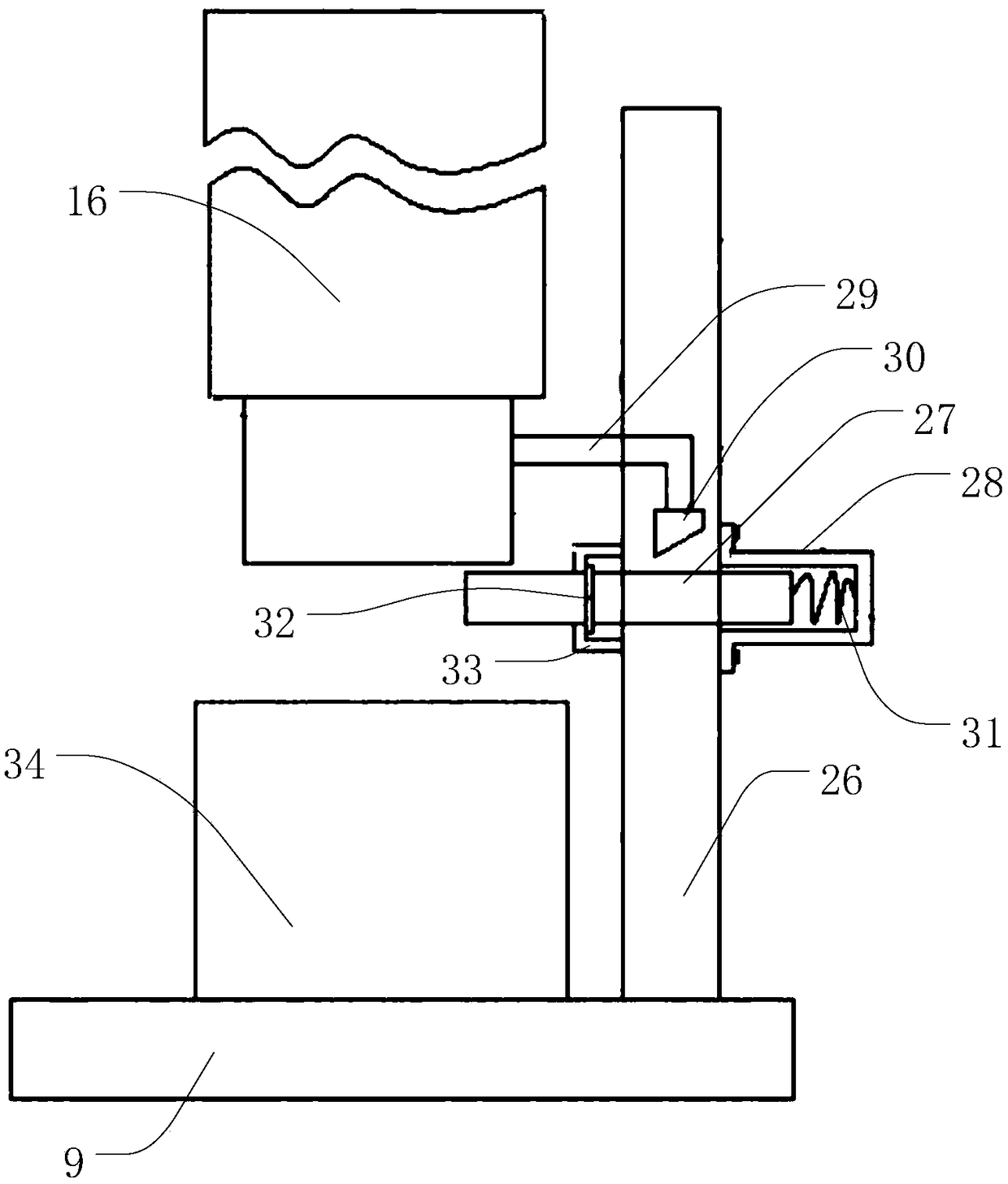

[0023] The invention discloses a buffer device for position limitation. The first fastening plate 1 is used to connect with the vibration-reducing and isolating device. Since the first fastening plate 1 and the top of the position-limiting seat have a position-limiting distance, the ship is Under the impact of waves or swinging in a maneuvering state, the power equipment installed with the vibration reduction and isolation device will shake in the direction of the limit seat; since the first fastening plate 1 is provided with a spherical groove on the side facing the limit seat, and the limit One end of the guide rod 16 is hemispherical, and one end of the limit guide rod 16 can passively slide and fit with the spherical groove. One end of bar 16 contacts, and one end of limit guide bar 16 can slide in the spherical groove; It will freely rotate and slide axially in the ball bearing to adapt to the shaking of power equipment equipped with vibration-reducing and isolating devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com