Heat collecting device for high-precision temperature sensor detection

A technology of temperature sensor and heat collecting device, which is applied in the direction of measuring device, thermometer test/calibration, thermometer, etc., to achieve the effect of close collection temperature position, accurate detection and small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

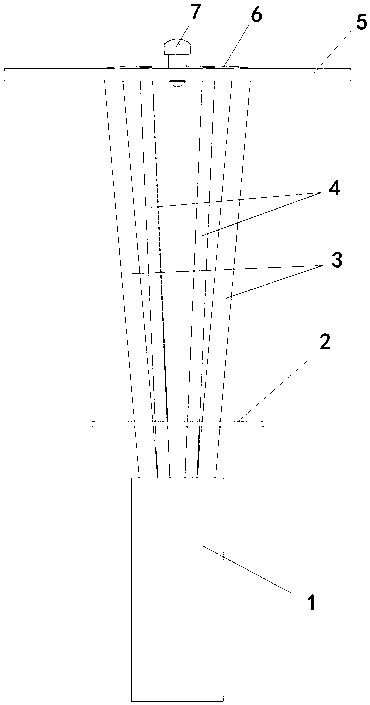

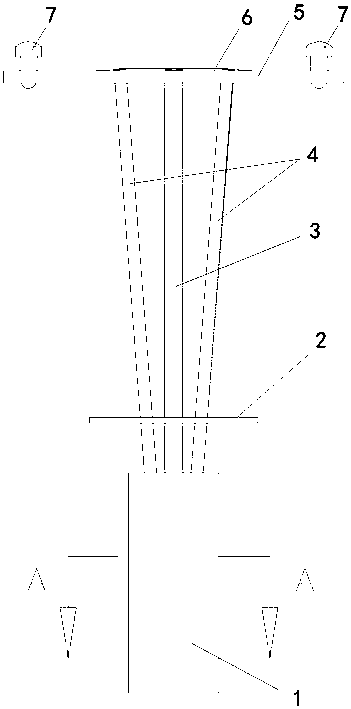

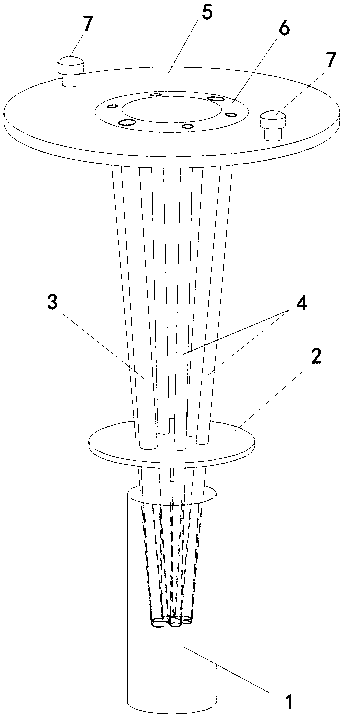

[0012] Such as Figure 1~4 Shown: the special heat collection device for high-precision temperature sensor detection of the present invention includes a mounting plate 5 and a copper column 1 located below the mounting plate 5, and a standard instrument insertion tube 3 and a sensor are arranged between the mounting plate 5 and the copper column 1 Insert tube 4.

[0013] Both the lower ends of the standard instrument insertion tube 3 and the sensor insertion tube 4 are inserted into the interior of the copper column 1 and fixedly connected with the copper column 1 by means of welding, bonding or fastening. The lower ends of the standard insertion tube 3 and the sensor insertion tube 4 are close to each other.

[0014] The upper ends of the standard insertion tube 3 and the sensor insertion tube 4 are fixedly connected by welding to the mounting plate 5 and distributed uniformly along the circumference, and the upper ports of the standard insertion tube 3 and the sensor insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com