Tractor resistance detection device

A detection device, tractor technology, applied in the direction of measuring device, force/torque/work measuring instrument, measuring force, etc., to achieve the effect of sensitive and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

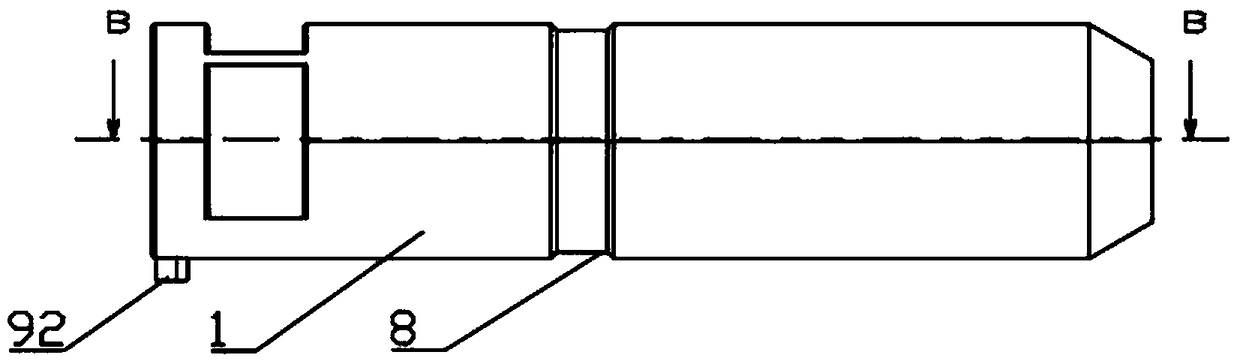

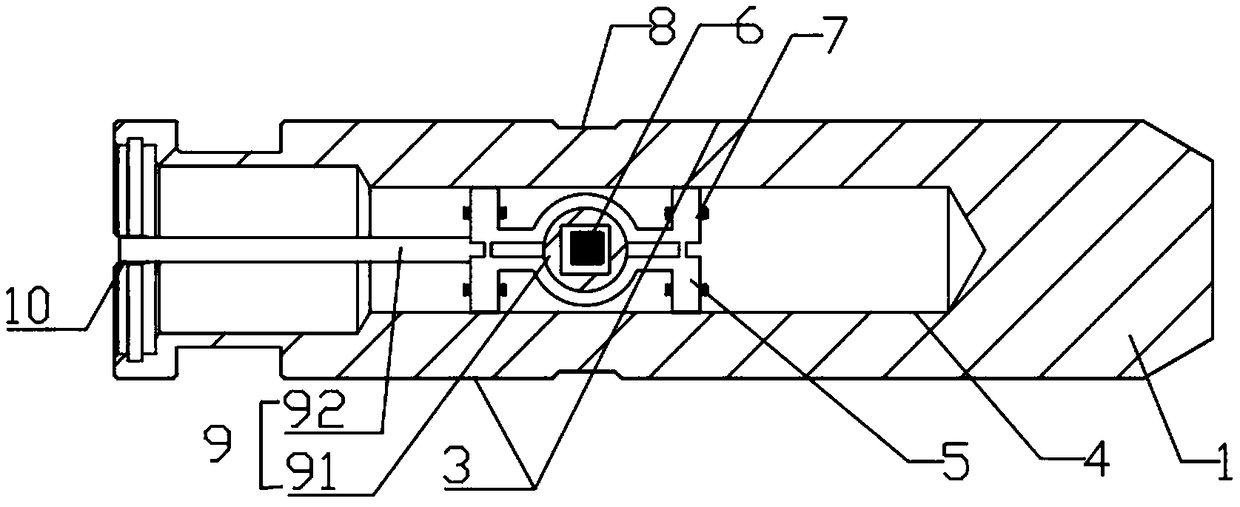

[0034] like Figure 1 to Figure 2 As shown, a tractor resistance detection device includes a shear force sensing shell 1, an electric signal conversion device 2 is arranged inside the shear force sensing shell 1, and the electric signal conversion device 2 is set as a piezomagnetic force sensor. The sensor is connected with an electric signal output control circuit.

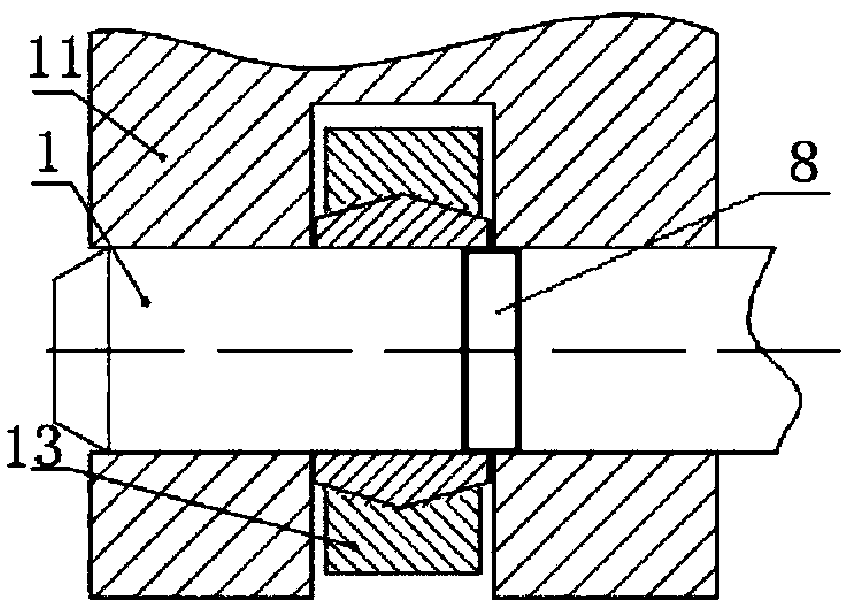

[0035] Further, the shear force sensing shell 1 is set in the shape of a round pin; the interior of the shear force sensing shell 1 is provided with an inner hole 4; the inner hole 4 is provided with a pressure sensor 5; the pressure sensor 5 includes an excitation magnetic core 6, and the excitation magnet The core 6 is arranged in the inner hole facing the shear concentration area 3, and the left and right sides of the excitation core 6 are provided with induction cores 7, and the longitudina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com