Liquid crystal display device

A technology for liquid crystal display devices and display areas, which is applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of reducing product yield, scratching wiring, etc., and achieve the effects of reducing product costs, strengthening protection, and reducing poor display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with examples, which are only preferred implementations of the present invention, and are not limitations of the present invention.

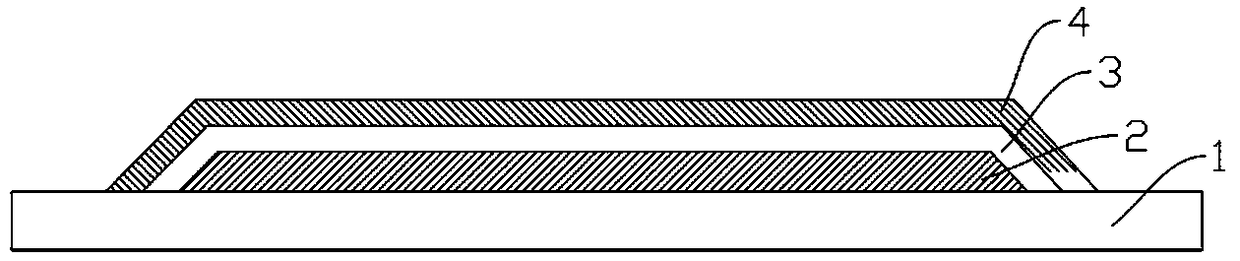

[0022] figure 1 It is a structural schematic diagram of a traditional liquid crystal display device, which includes: a substrate, the substrate includes a display area and a frame area surrounding the display area; a gate scan line layer located in the frame area on the substrate ; a first insulating layer located on the gate scan line layer; a second insulating layer located on the first insulating layer. During the production process of this traditional liquid crystal display device, part of the gate scanning lines will be exposed, and both manual and machine operations may scratch the wiring lines, resulting in poor display.

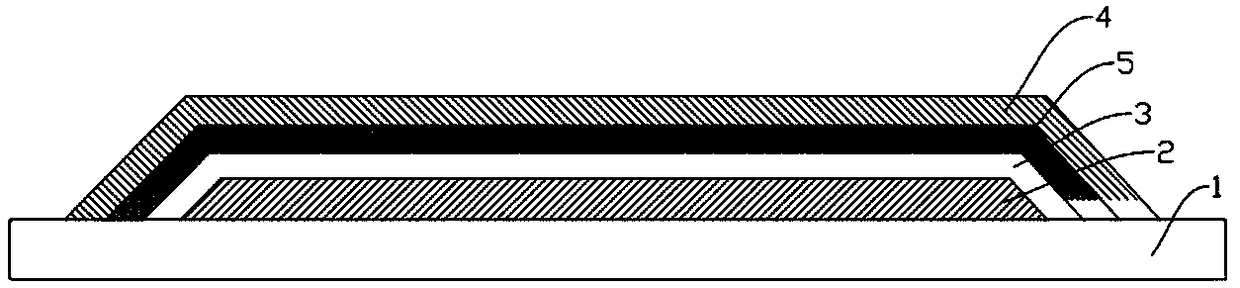

[0023] Based on the above problems, the present invention provides a liquid crystal display device, see figure 2 , which includes:

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com