Non-dormancy treatment method for peaches in sunlight greenhouse

A technology of solar greenhouse and dormancy treatment, applied in the field of planting industry, can solve problems such as inability to produce fresh peaches, and achieve the effects of increasing plant stress resistance, increasing economic benefits, and changing nutritional needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Effects of Spraying PP333 at Different Periods on the Differentiation Process of Peach Blossom Buds

[0029] In order to ensure that the flower bud differentiation of the peach tree enters the pistil stage before the canopy is closed (September 1). The process of spraying PP333 in different periods on the differentiation process of peach flower buds was studied. PP333 adopts paclobutrazol produced by Sichuan Guoguang.

[0030] 1. Materials and methods

[0031] (1) Experimental materials

[0032] The materials were taken from spring snow peaches in the Spring Festival Peach Experimental Greenhouse of Nantang Fruit Planting Professional Cooperative in Luannan County. The tree is 4 years old and the tree is strong. Postharvest pruning was performed on April 22, 2012.

[0033] (2) Test treatment

[0034] The periods of spraying PP333 were set as: May 18, June 18 and July 18. The concentration of spraying 15% PP333 is 40 times liquid, and the second spraying is carrie...

Embodiment 2

[0045] Investigation on the Growth Results of Spring Snow Peach by Spraying Compound Pomian Liquid in Different Years

[0046] 1. Materials and methods

[0047] (1) The materials were taken from the spring snow peaches in the Spring Festival Peach Experimental Greenhouse of the Nantang Fruit Planting Professional Cooperative in Luannan County. The tree is 4 years old, the tree body is strong, and the planting density is 1m×1m.

[0048] The formula of the compound sleeping liquid of this embodiment is calculated in 1L: copper sulfate 6%, 50% cyanamide 1.2%, calcium phosphate 1.2%, magnesium sulfate 2.4%, 5% naphthalene acetic acid 0.25%, organosilicon 0.35%, 1.6% Diethyl hexanoate 0.35%, indole acetic acid 0.08%, sodium nitrophenolate 1.2%, water 87%.

[0049] (2) Processing methods for different years

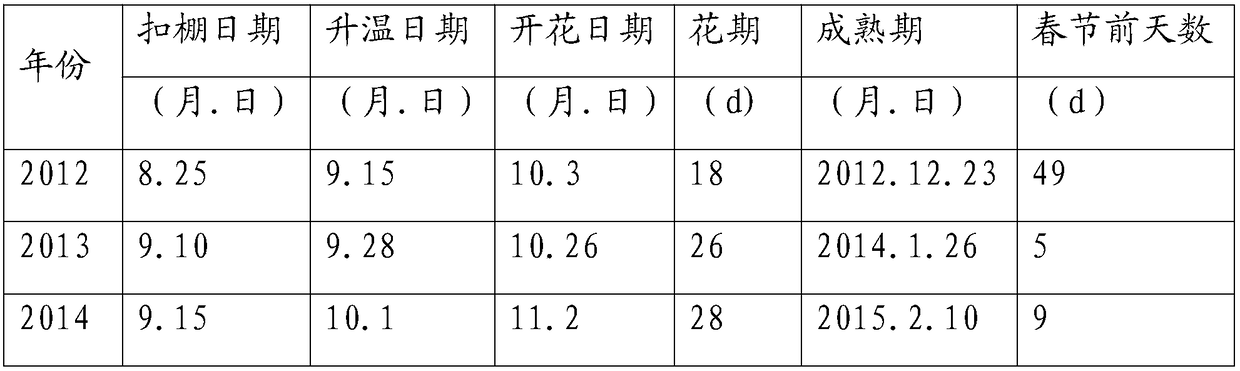

[0050] Table 1 The temperature rise time of the canopy in different years

[0051] years

Shed period (month, day)

Warming date (month, day)

2012

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com