A kind of vibrating screening equipment for block vegetable processing with horizontal air blowing

A vegetable processing and vibration screening technology, applied in the direction of sieve, separation of solids from solids by air flow, solids separation, etc., can solve the problems of a lot of manual labor, low work efficiency, etc. Guaranteed screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

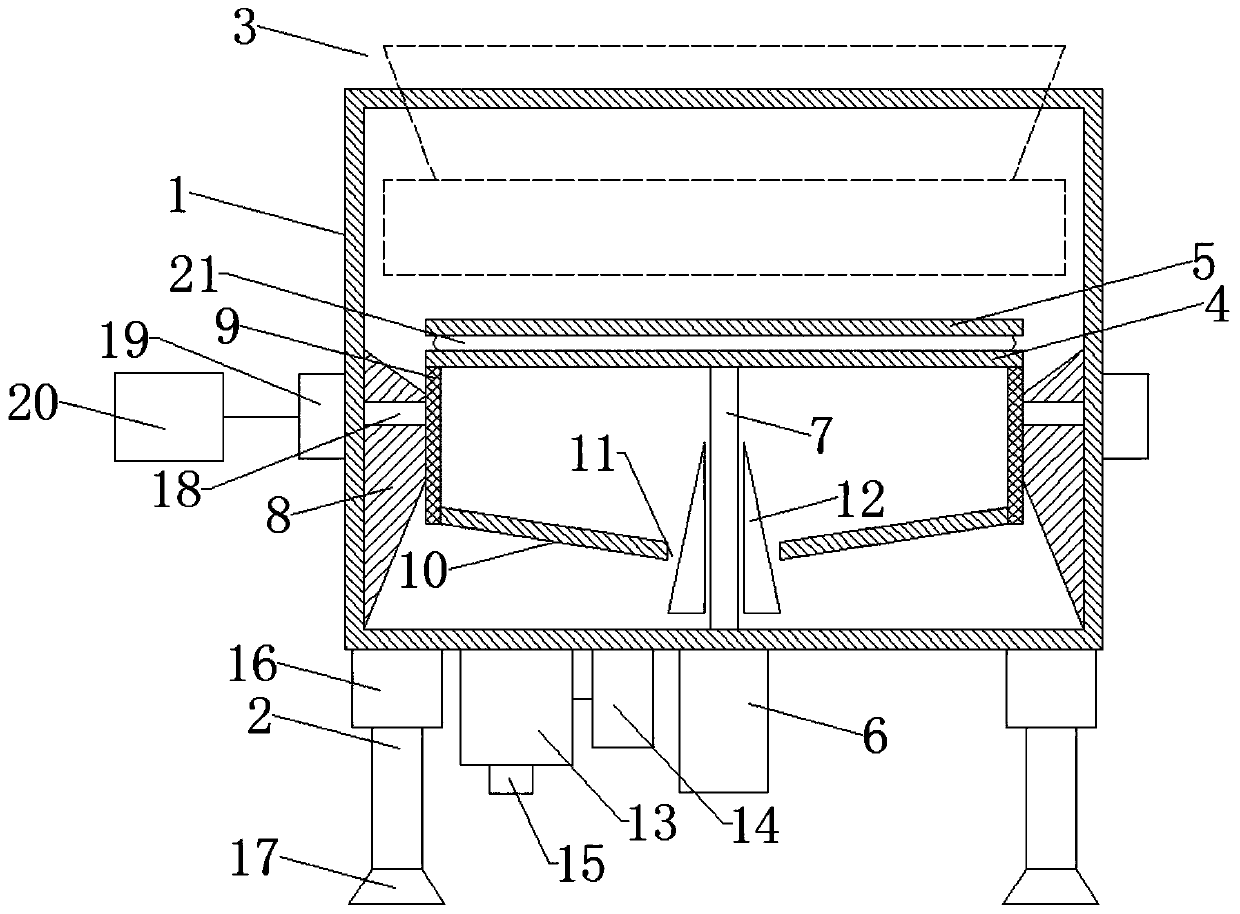

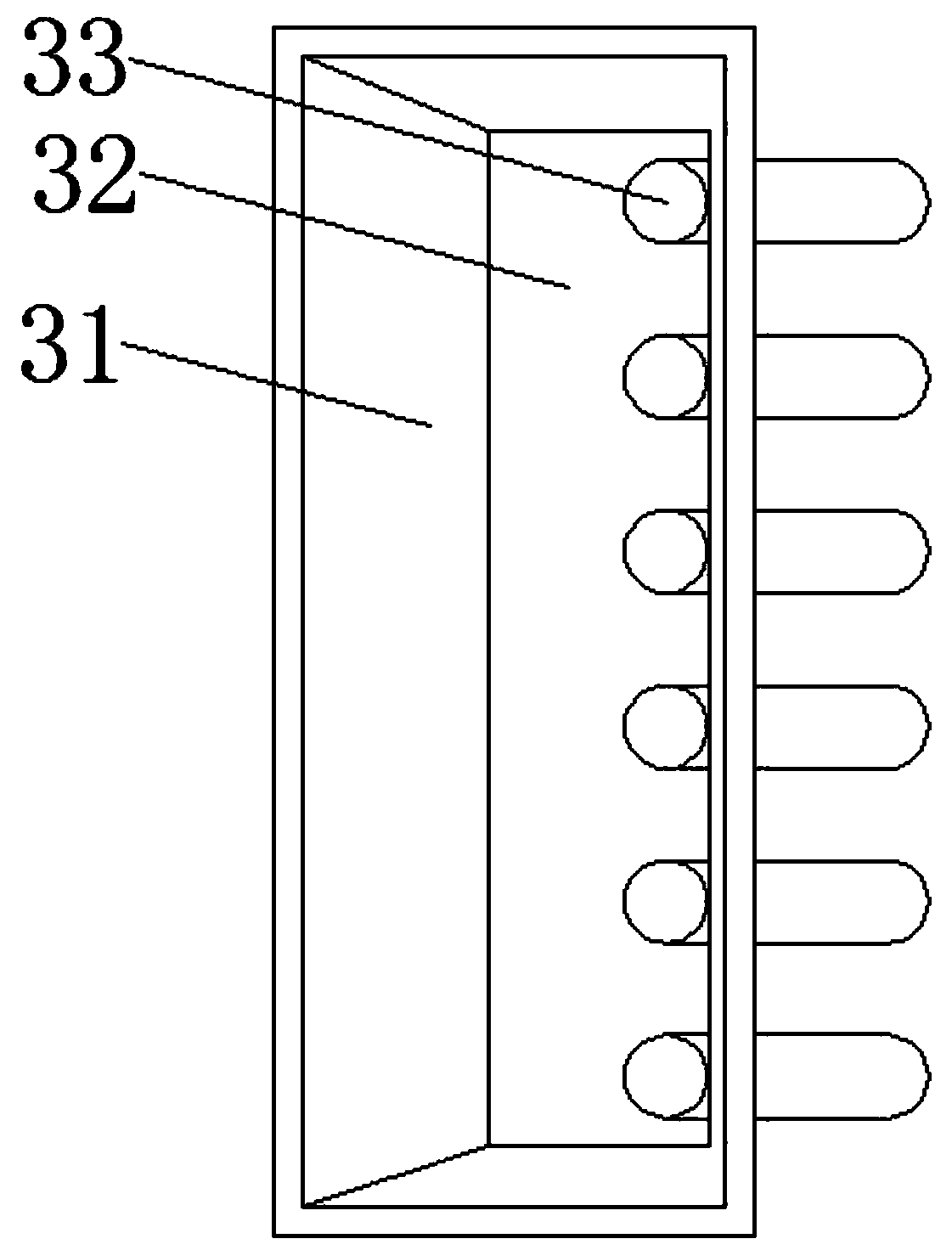

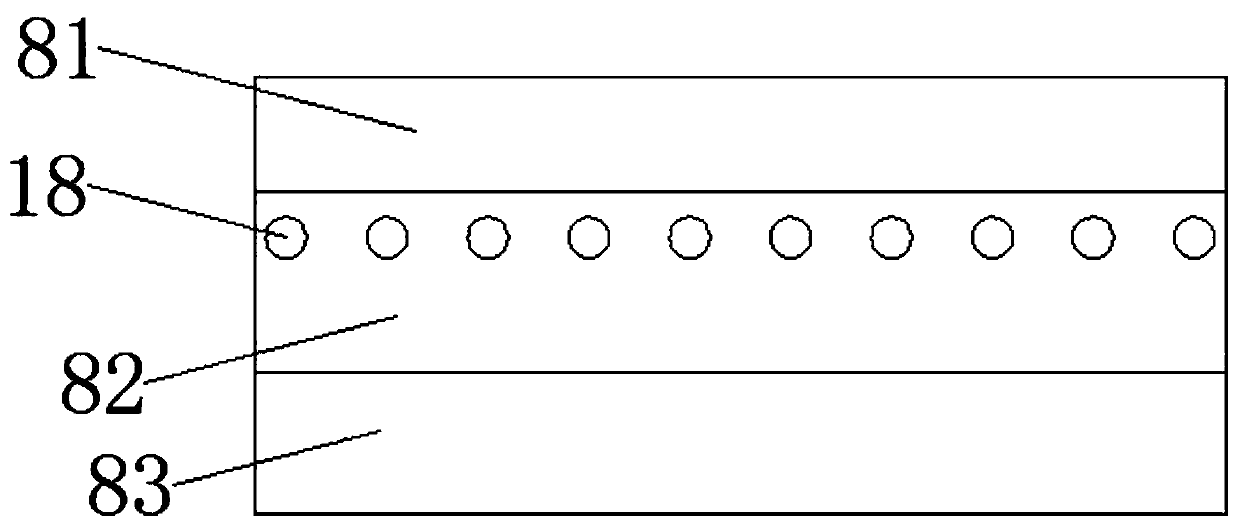

[0024] Please refer to the figure, in the embodiment of the present invention, a kind of vibratory screening equipment for block vegetable processing with horizontal air blowing includes a housing 1, supporting legs 2, lifting mechanism 6 and exhaust fan 14; the supporting legs 2 are arranged on the housing On the four corners of the bottom of 1, the outrigger 2 and the bottom of the housing 1 are connected by a vibration mechanism 16. The vibration mechanism 16 is composed of a vibration motor and a vibration spring to make the housing 1 on the outrigger 2 vibrate, which is convenient for screening. A support foot 17 is fixedly installed on the lower end of the support leg 2, and the material of the support foot 17 is rubber, which plays the role of buffering and noise reduction; the upper end side wall of the housing 1 is connected with a feeding mechanism 3, and the block vegetables are fed from the feeding mechanism. 3 is loaded into the housing 1, the feeding mechanism 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com