Annular cleaning equipment used for ocean engineering platform

A technology for cleaning equipment and marine engineering, which is applied in the directions of cleaning methods using liquids, cleaning methods using gas flow, cleaning methods and utensils, etc. It can solve the problems of dangerous work efficiency, manual operation, low performance, etc., to expand the cleaning area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

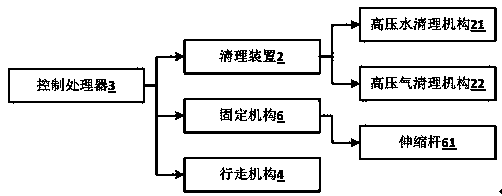

[0027] refer to figure 1 , figure 1 It is a system connection diagram of a ring-shaped cleaning device used for offshore engineering platforms provided by the present invention.

[0028] A circular cleaning device for offshore engineering platforms, comprising: a body 1 , a cleaning device 2 , and a control processor 3 .

[0029] The main body 1 is annular, and the inner side of the main body 1 is provided with a traveling mechanism 4, which is connected with the control processor 3, and the control processor 3 outputs a walking signal to the traveling mechanism 4, and the traveling mechanism 4 moves according to the walking signal. The traveling mechanism 4 can be a crawler belt or a roller, and the traveling mechanism 4 is driven by a control signal output by the control to move in a designated direction. The walking signal output to the running mechanism 4 may include the walking direction and distance, and the running mechanism 4 moves to a designated position according ...

Embodiment 2

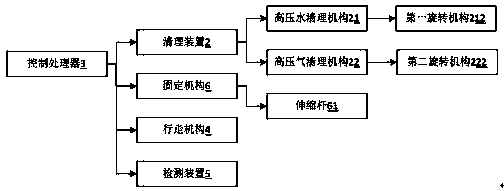

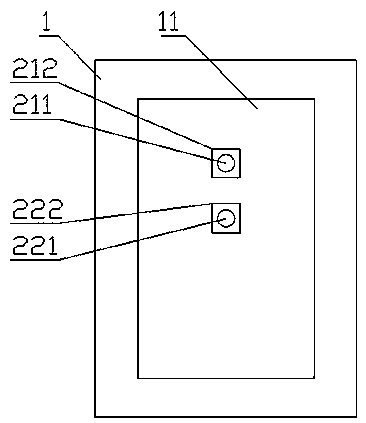

[0035] refer to Figure 2-3 , figure 2 The system connection diagram of the second annular cleaning equipment used for offshore engineering platforms provided by the present invention; image 3 It is a schematic diagram of the second ring-shaped cleaning equipment used for offshore engineering platforms provided by the present invention.

[0036] This embodiment is basically the same as the first embodiment above, except that, preferably, the main body 1 has an inner groove 11 . The high-pressure water cleaning mechanism 21 also includes a water outlet 211 , and the water outlet 211 is disposed in the groove 11 . The high-pressure air cleaning mechanism 22 also includes an air outlet 221 , and the air outlet 221 is disposed in the groove 11 . The groove 11 is disposed on the body 1 and is recessed inward, and the space formed between the groove 11 and the surface of the object can be a working space. The water outlet 211 and the air outlet of the high-pressure water clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com