Water cooling machine shell heat core box electric heating device

A technology of electric heating device and hot core box, applied in casting and molding equipment and other directions, can solve the problems of uneven heating, unsatisfactory sand core deformation and filling, uneven bonding density, etc., to achieve stability, temperature synchronization and consistency, The effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

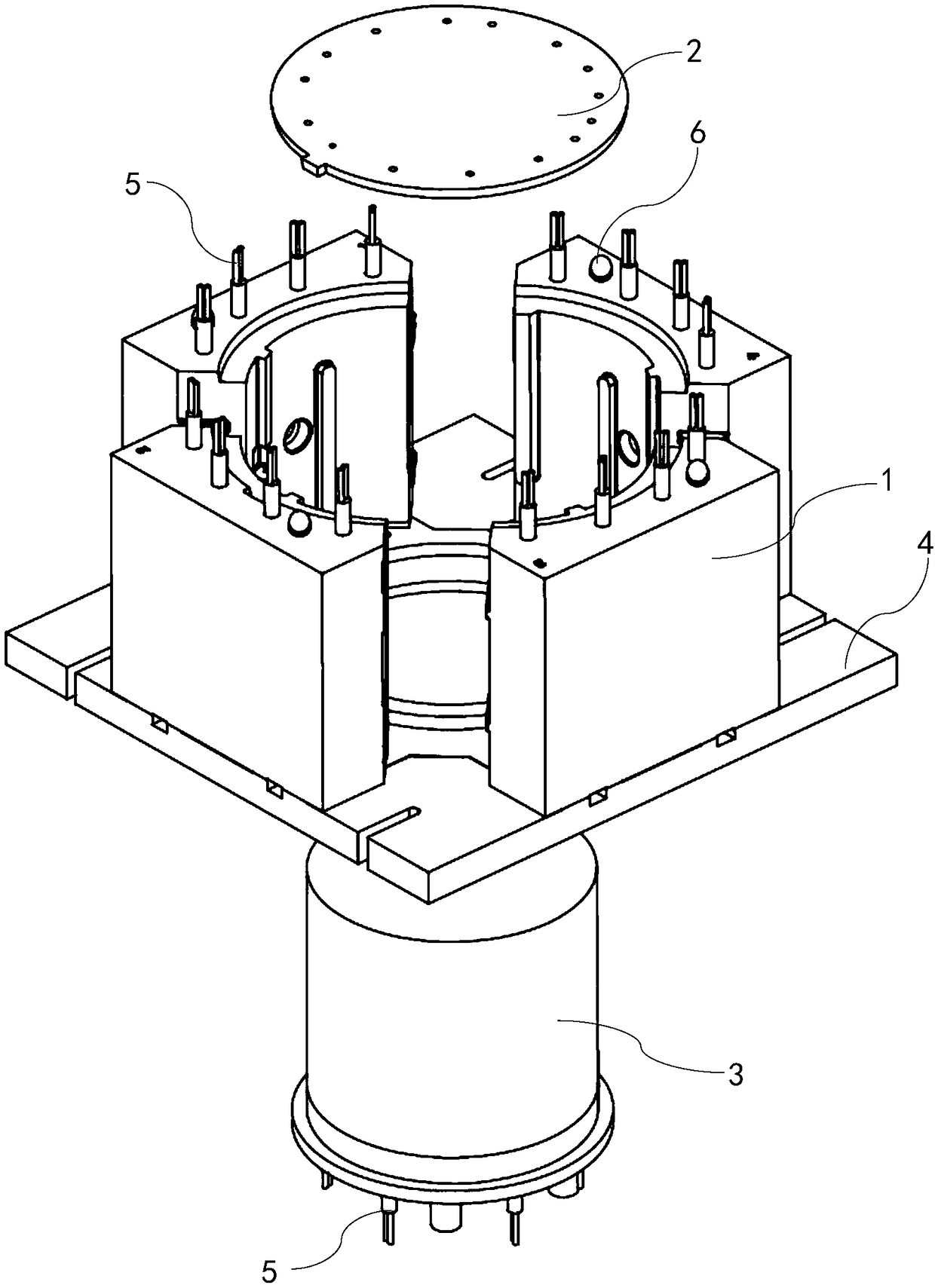

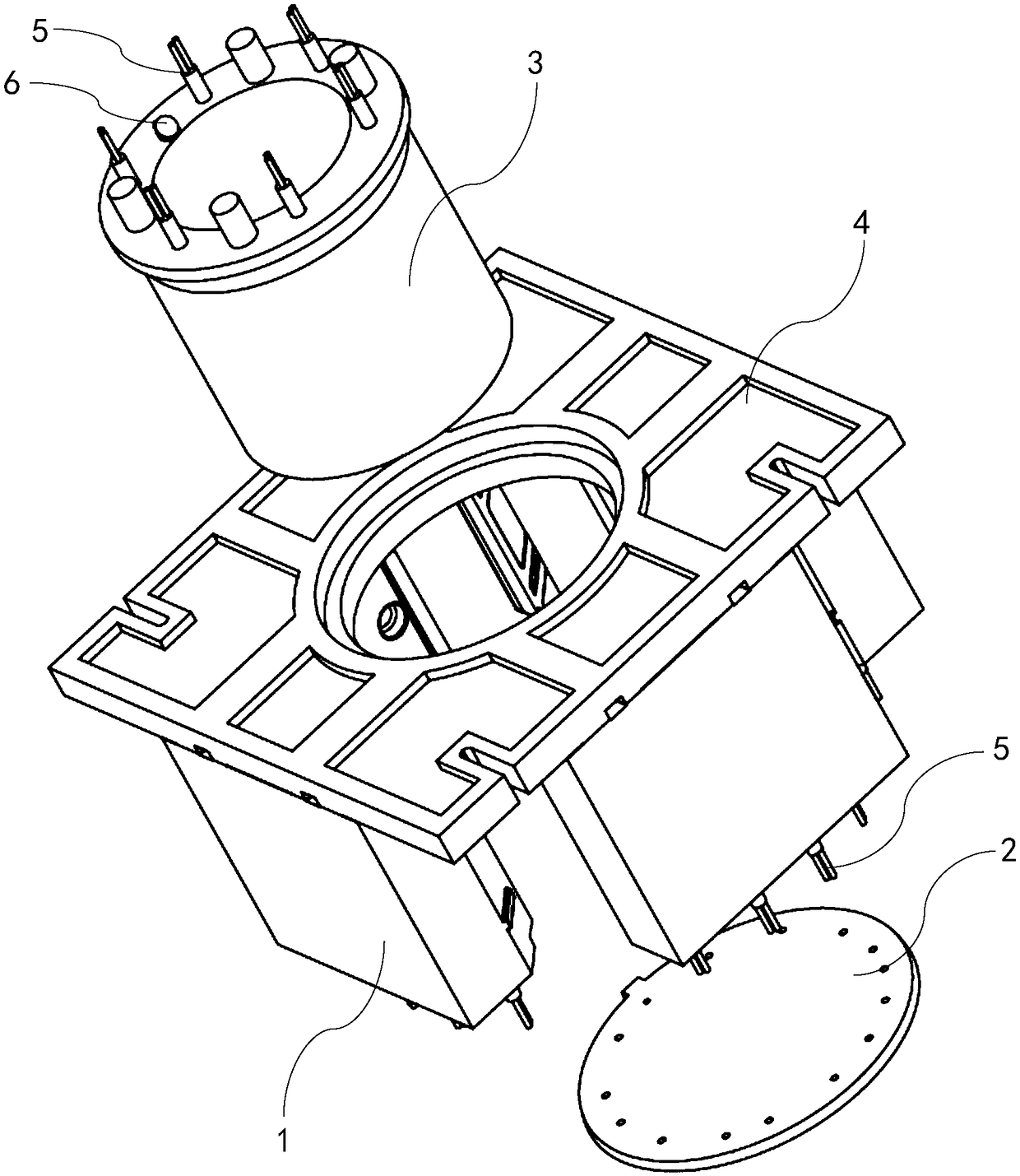

[0018] Please refer to the attached Figure 1-2 , a water-cooled casing hot core box electric heating device provided by the present invention, which includes a plurality of core box bodies 1 to form a mold body with a cavity, a sand shooting plate 2 covering the upper part of the cavity, and a set The extracting core body 3 in the cavity and the core plate 4 covered at the lower end of the cavity; the cavity is cylindrical, and the same number of heating tubes 5 are arranged in the core box body 1, The heating tubes 5 are arrayed in an arc shape in the core box body 1 and are at the same distance from the inner wall of the core box body 1 .

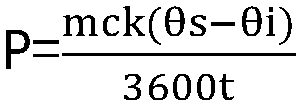

[0019] Based on the above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com