An improved diversion sheath, end buckle and wiper

A sheath and wiper technology, applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problem of lack of simple and streamlined wiper shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

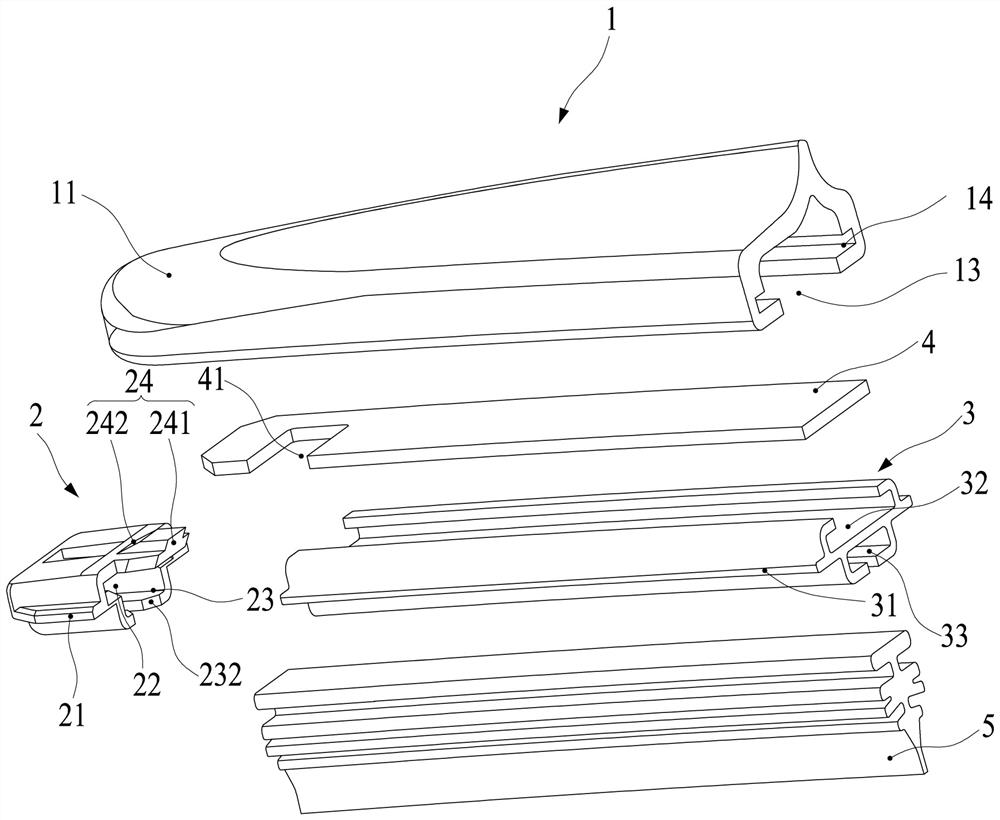

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

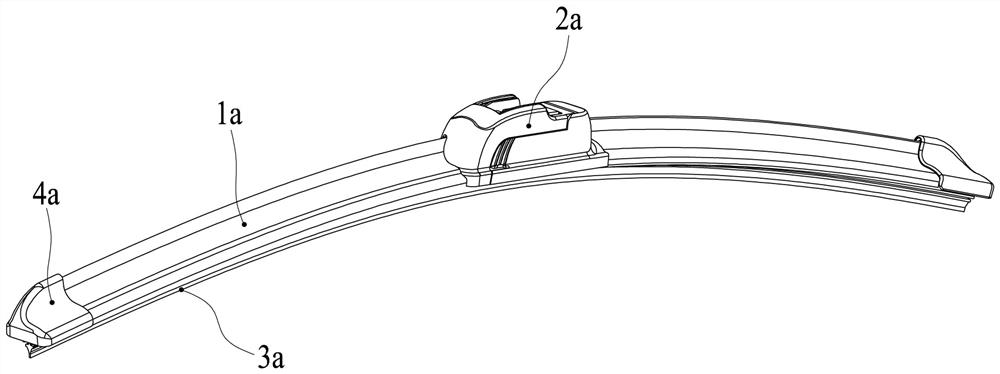

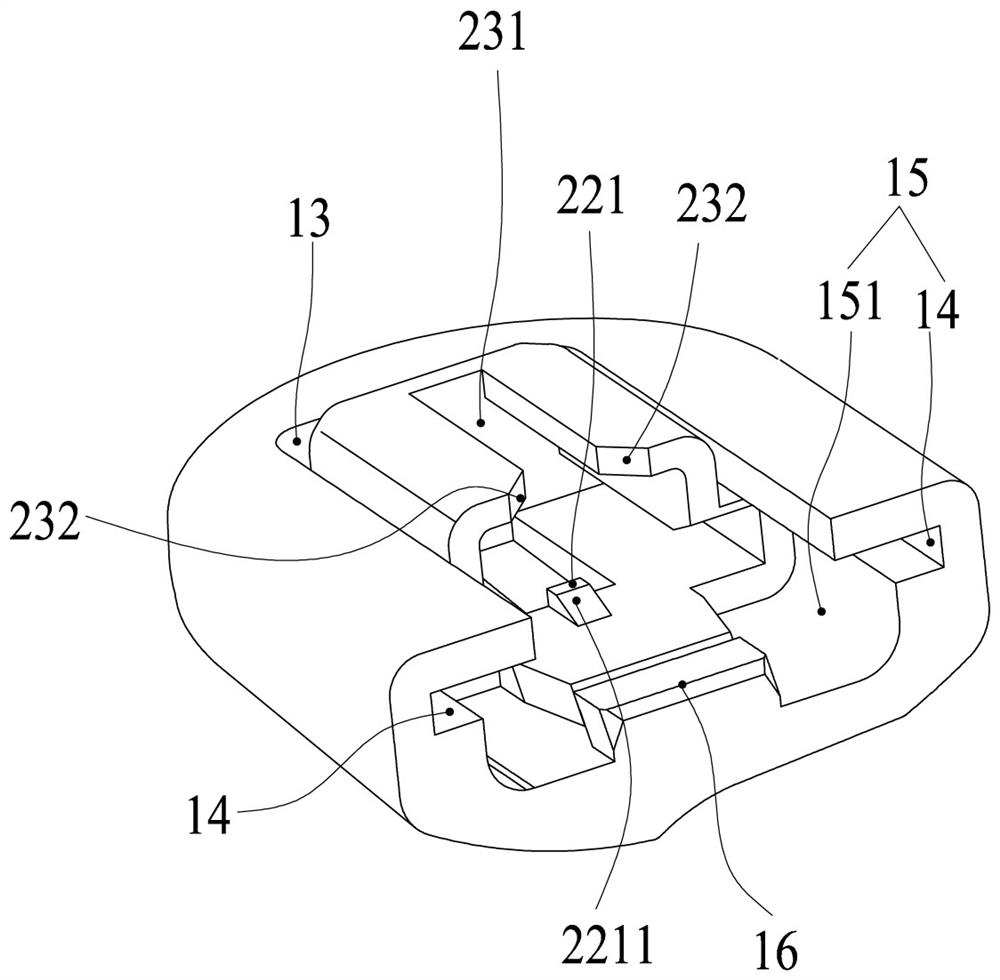

[0038] Such as figure 2 , Figure 7 , the present invention discloses an improved diversion sheath 1, which is in the shape of a strip, one end along the length direction of the diversion sheath 1 is a closed end 11, and the other end is an insertion end 12 for inserting a bearing tab 3, The bottom opening 13 of the diversion sheath 1 has a chute 14 extending along the length direction of the diversion sheath 1 on the left and right sides of the inner cavity, and there is a built-in end buckle on the closed end 11 side of the diversion sheath 1 2, the accommodating groove 15 is provided with at least one position-limiting structure 16 for preventing the displacement of the end button 2 along the length direction of the flow guide sheath 1.

[0039] More specifically, the accommodating groove 15 is composed of a top positioning reference pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com