Method for improving methane recovery by self-improvement of coal seam induced by nitrogen injection

A recovery factor and coal seam technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of difficult gas injection, difficult to guarantee, limited recovery effect, etc., to avoid coal seam stress sensitivity, The effect of improving the permeability and the permeability of the coal seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the content of the present invention, and are not intended to limit the present invention.

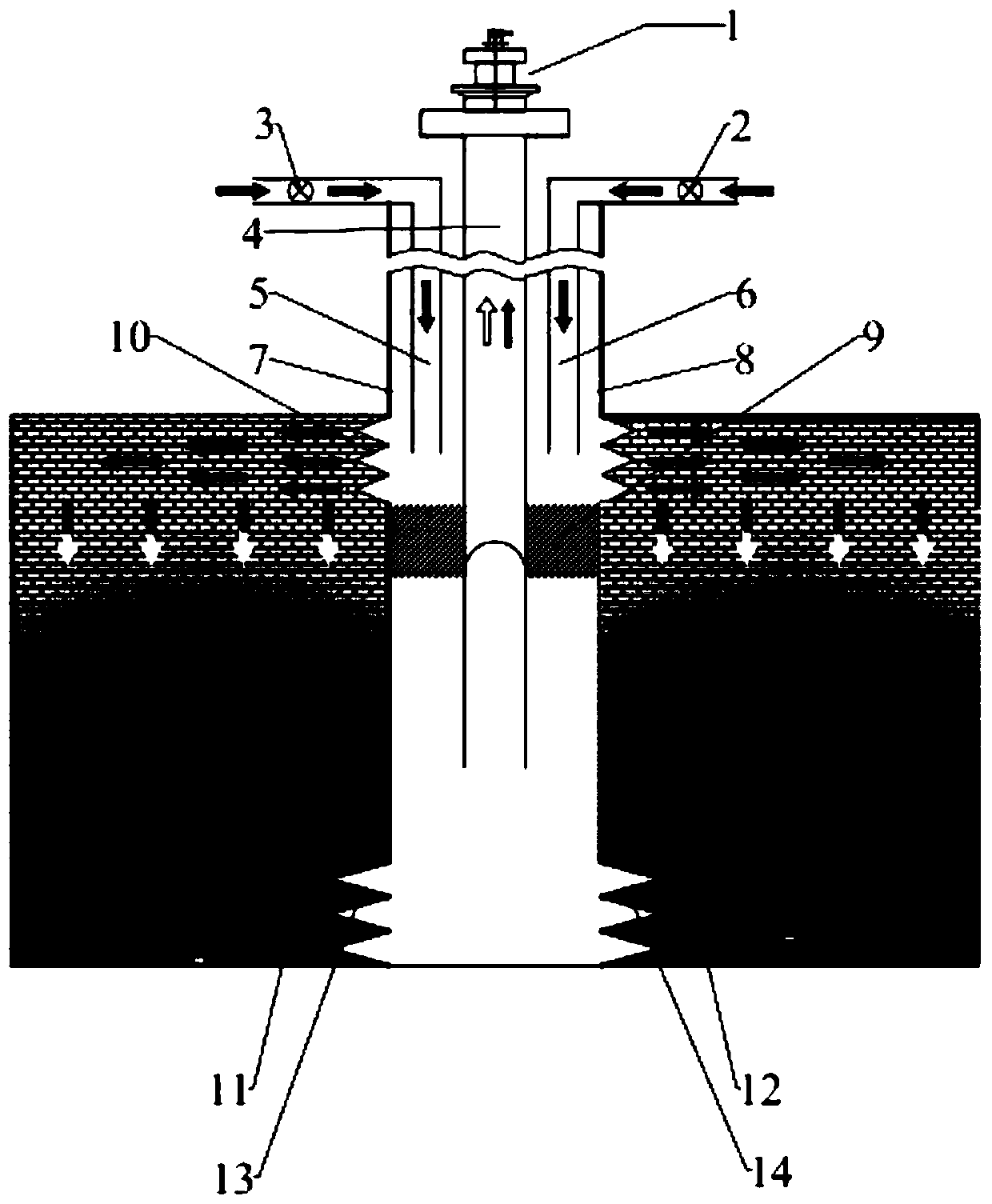

[0023] The method for enhancing methane recovery by nitrogen injection to induce self-improvement of coal seam includes the following operations when extracting methane from coal seam:

[0024] 1) Drill through the entire coal seam and carry out cementing and completion, and then run the production casing to the middle of the coal seam. A nitrogen injection pipeline connected to the nitrogen source is installed beside the production casing; a seal is also installed at a certain depth from the top of the coal seam. Packers, which separate the top of the coal seam from the casing annulus below;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com