A kind of mixed treatment method of low flash point organic solvent and high concentration organic waste liquid

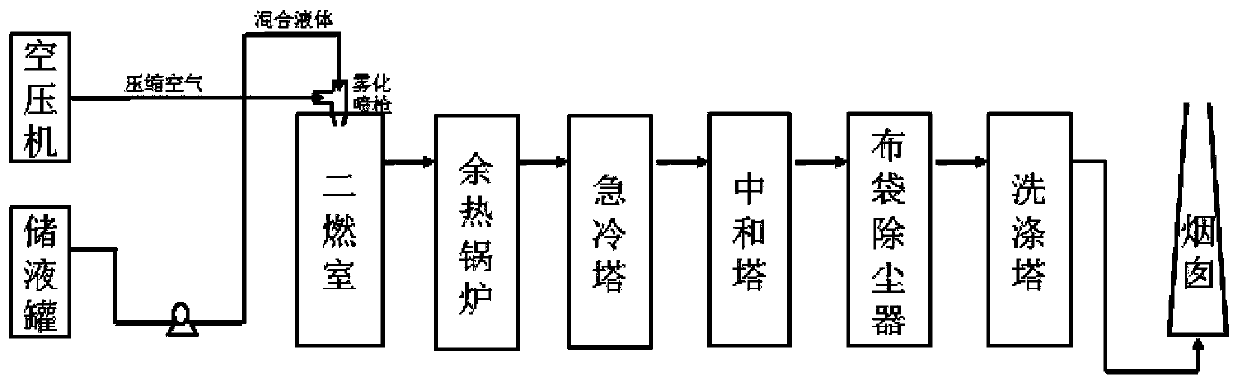

A technology of organic waste liquid and organic solvent, which is applied in the combustion method, combustion type, lighting and heating equipment, etc., can solve the problems of high concentration organic waste liquid that is difficult to degrade, has peculiar smell, and has complex components, and achieves comprehensive resource treatment. The effect of utilization, safe storage and transportation, and safe incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The low-flash point organic solvent referred to in the present invention refers to an organic solvent with a flash point lower than 28° C., and the high-concentration organic waste liquid refers to COD above 2000 mg / L, and the ratio of BOD to COD is less than 0.3.

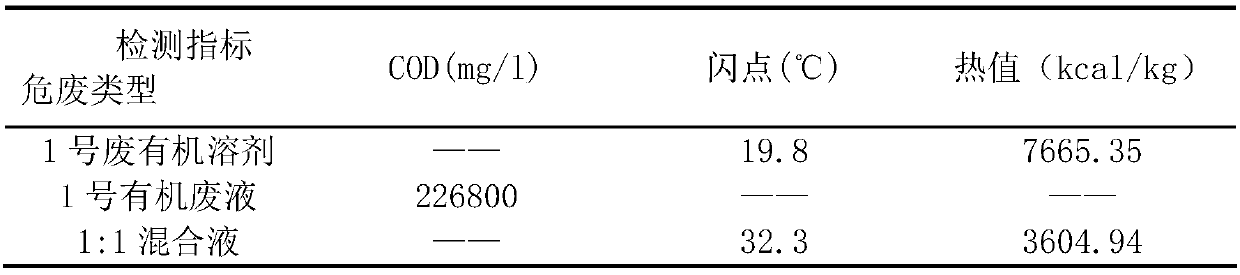

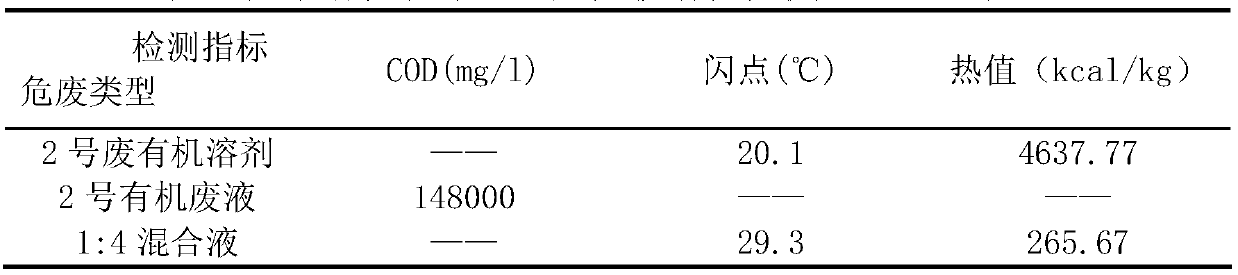

[0011] Analyze the main components of low-flash point organic solvents and high-concentration organic waste liquids to determine whether they are mutually soluble, and choose mutually soluble organic solvents and high-concentration organic waste liquids to mix evenly without stratification. Mixing can be carried out at a ratio of 1:1 first, and then a combustion test is carried out under open flame conditions to observe whether there is a flame. According to the situation of the flame, adjust the ratio of the mixed liquid so that the mixed liquid can just burn.

[0012] Then test the calorific value of the mixed solution. If the calorific value is greater than 5000Kcal / kg, adjust the ratio of the organic solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com