Horizontal loading test system and method for bearing capacity performance of U-shaped shield duct piece structure

A shield segment, loading test technology, applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, measuring devices, etc., can solve the problem of large force and material consumption, poor economy, and large structural size and other problems, to achieve the effect of less material consumption, reduced layout density, and uniform structural stress

Inactive Publication Date: 2018-10-16

SOUTHWEST JIAOTONG UNIV +2

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In the past, the shield segment prototype loading test devices were either vertical or horizontal, and many of them were circular segments without reaction walls. They were pulled against each other according to symmetry. There was almost no unbalanced force, and most of the reaction

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

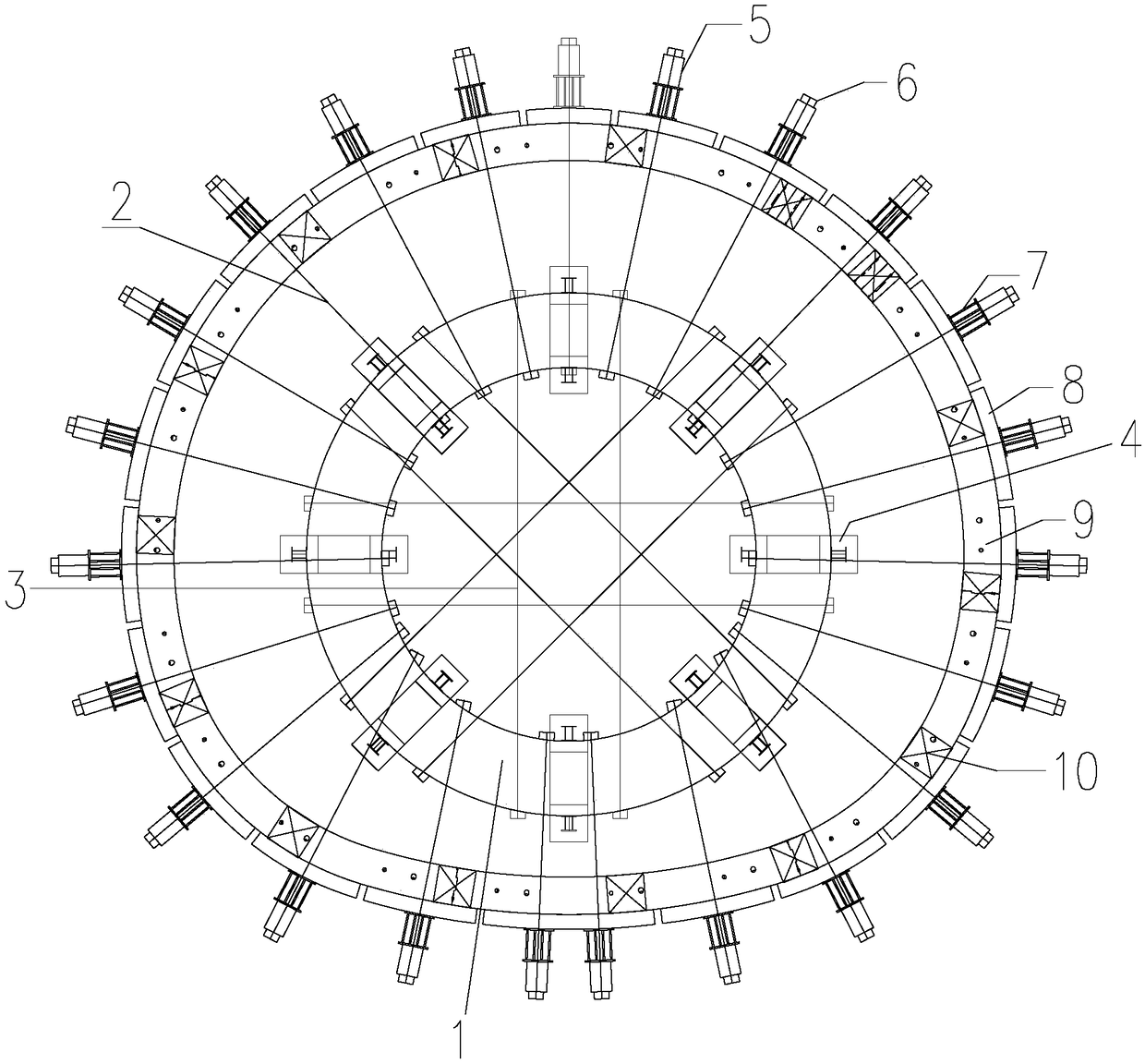

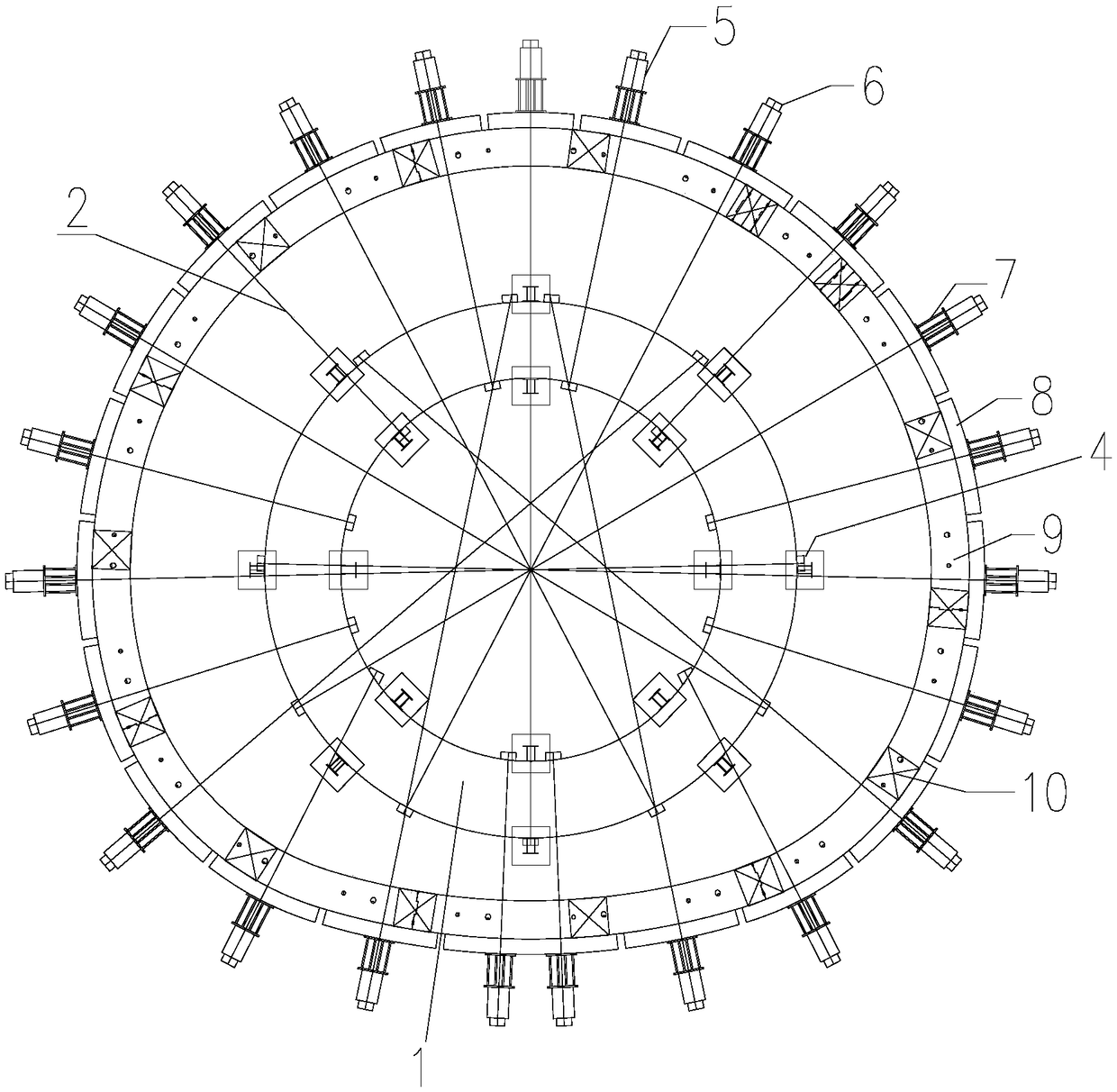

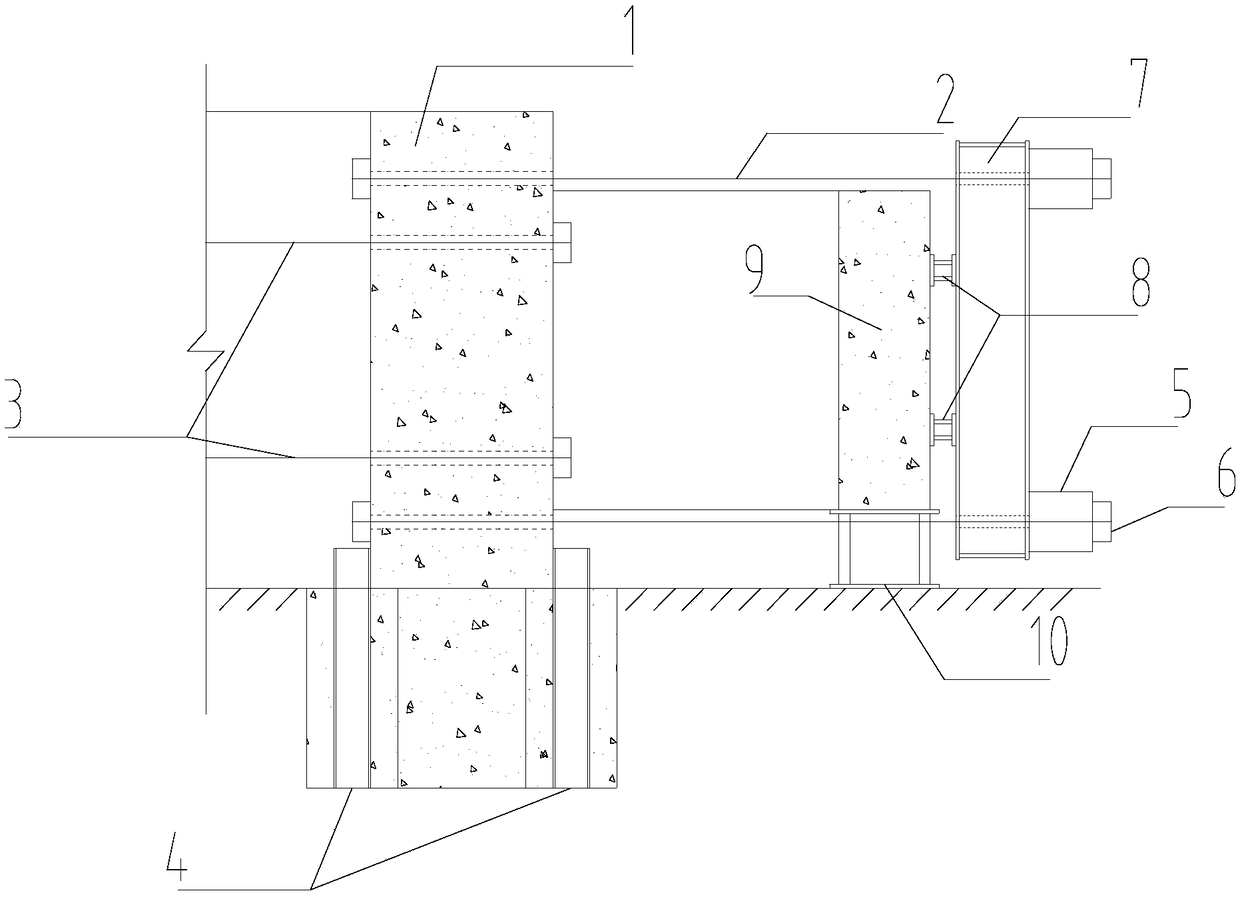

The invention discloses a horizontal loading test system for the bearing capacity performance of a U-shaped shield duct piece structure. The system comprises a duct piece support, a loading longitudinal beam, a reinforced concrete reaction wall, profiled steel reaction columns, a jack, an anchorage device, an active tensed steel strand and a passive tensed steel strand, wherein the duct piece support is provided with duct pieces which are spliced into a ring; a loading ring beam is arranged on the outer side of a duct piece ring; the loading ring beam is arranged on the outer side in a surrounding manner; the loading longitudinal beam is arranged on the outer side of the loading ring beam; the jack is arranged on the outer side of the loading longitudinal beam; the jack is connected with the reinforced concrete reaction wall through the active tensed steel strand anchored through the anchorage device; the reinforced concrete reaction wall is arranged inside the duct piece ring and is fixed through the profiled steel reaction columns; the profiled steel reaction columns are arranged on the inner and outer sides of the reinforced concrete reaction wall, and are connected with the jack through the active tensed steel strand anchored through the anchorage device; the profiled steel reaction columns are arranged on the inner and outer sides of the reinforced concrete reaction wall.

Description

technical field [0001] The invention relates to the field of performance test of shield segment bearing capacity, in particular to a horizontal loading test system and method for the bearing capacity performance of a horseshoe-shaped shield segment structure. Background technique [0002] The shield segment is the main assembly component of shield construction and the innermost barrier of the tunnel, which bears the role of resisting soil pressure, groundwater pressure and some special loads. The shield segment is the permanent lining structure of the shield tunnel. The quality of the shield segment is directly related to the overall quality and safety of the tunnel, and affects the waterproof performance and durability of the tunnel. [0003] The test of the prototype segmental lining structure of the shield tunnel can more realistically test the detailed characteristics of the segmental lining structure and the mechanical properties of the structural bearing capacity, inst...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/08G01N3/02

CPCG01N3/02G01N3/08

Inventor 仇文革郑余朝申志军艾旭峰王刚伍军谢飞申德芳杨仲杰王江红夏勇

Owner SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com