Sensing operation module and terminal

A sensing module and module technology, which is applied in the input/output process of instruments, electrical digital data processing, and data processing, etc., can solve the problems of poor waterproofness and anti-static discharge performance, and inability to quantify pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

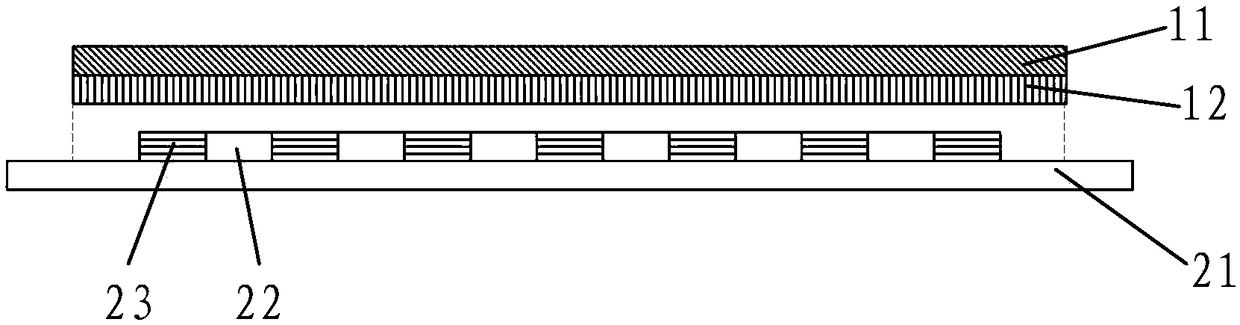

[0042] Embodiment 1: The material of the sensing element 22 is a material having a Hall effect.

[0043] Specifically, the sensing element 22 is made of a material having a Hall effect. Preferably, the outer surface of the inductive element 22 made of a material having a Hall effect does not protrude from the outer surface of the circuit 23 part, such as: the inductive element 22 and the circuit 23 arranged on the same surface of the insulating plate 21 are in a plane, In order to avoid increasing the overall thickness of the sensing operation module.

[0044] Preferably, the sensing element 22 can be made of graphene or semiconductor materials, such as germanium, silicon, gallium arsenide, indium arsenide, indium antimonide, with a thickness of about 20 μm. It has the characteristics of high mobility (mobility>2900cm2 / V·s), high Hall coefficient and good deformation recovery, and thin thickness to improve the overall sensitivity.

[0045] The magnetic material layer 12 adop...

Embodiment 2

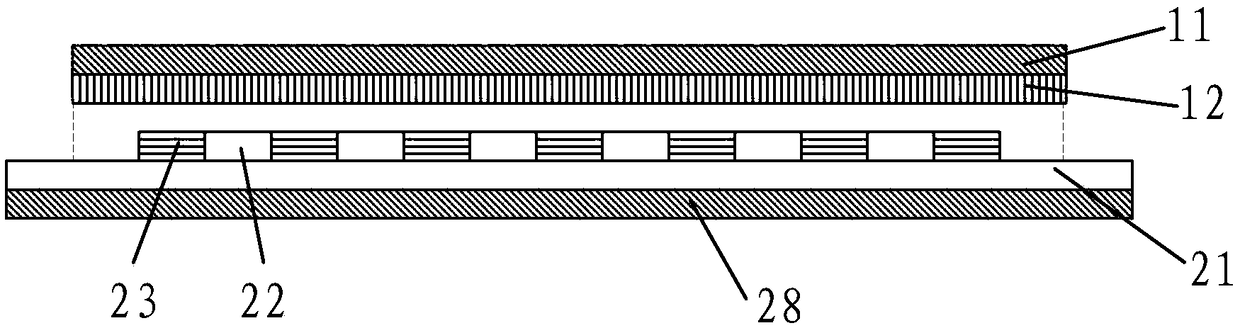

[0057] Embodiment 2: The material of the inductive element 22 is a material with a giant magnetic effect.

[0058] The specific inductive element 22 is made of materials with giant magnetic effect. Preferably, the outer surface of the inductive element 22 made of a material with a giant magnetic effect does not protrude from the outer surface of the circuit part, such as: the inductive element 22 and the circuit 23 arranged on the same surface of the insulating plate 21 are in a plane, so as to Avoid increasing the overall thickness of the sensing operation module.

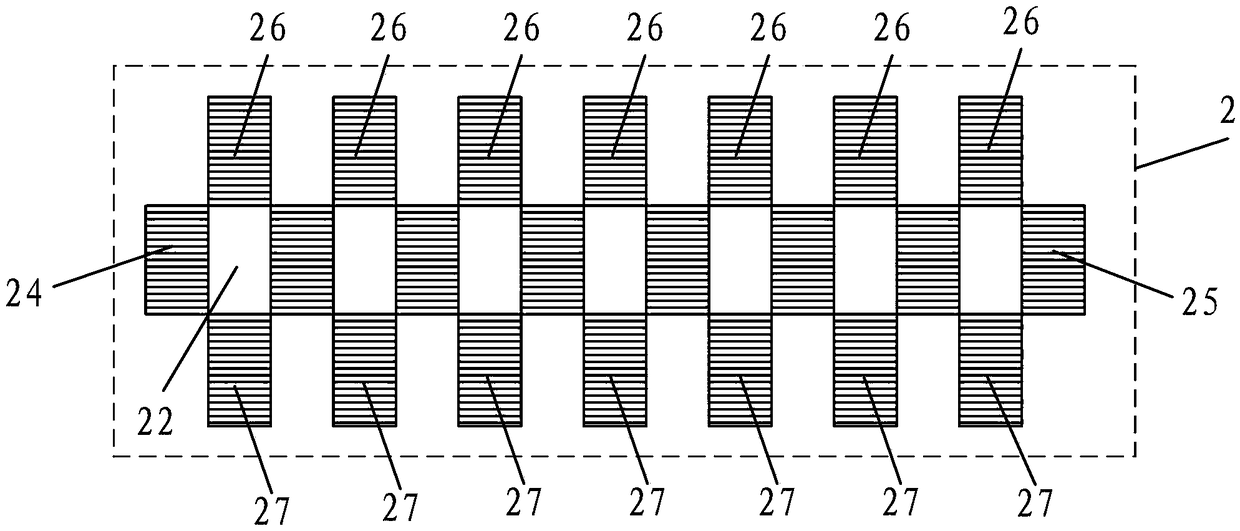

[0059] Such as Figure 5 , shows another example of the sensing module, wherein the sensing module 2 includes at least one sensing element 22 with Hall effect. Preferably, when the sensing module 2 includes at least two sensing elements 22, at least two sensing elements 22 are arranged in parallel; or each sensing element 22 is powered by an independent power supply.

[0060] Specifically, the first end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com