Charged particle beam device and sample processing method

A technology of charged particle beam and processing method, which is applied in the preparation of test samples, circuits, discharge tubes, etc., can solve the problems such as the inability to produce tiny sample pieces, the inability to accurately grasp the processing end point, and the reduction of the contrast of the processing surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, a charged particle beam device and a sample processing method using the charged particle beam device as one embodiment of the present invention will be described with reference to the drawings. In addition, each embodiment shown below is concretely demonstrated for better understanding of the gist of invention, Unless otherwise specified, this invention is not limited. In addition, in order to facilitate understanding of the features of the present invention, the drawings used in the following description may show enlarged main parts for convenience, and the dimensional ratio of each component may not necessarily be the same as the actual one.

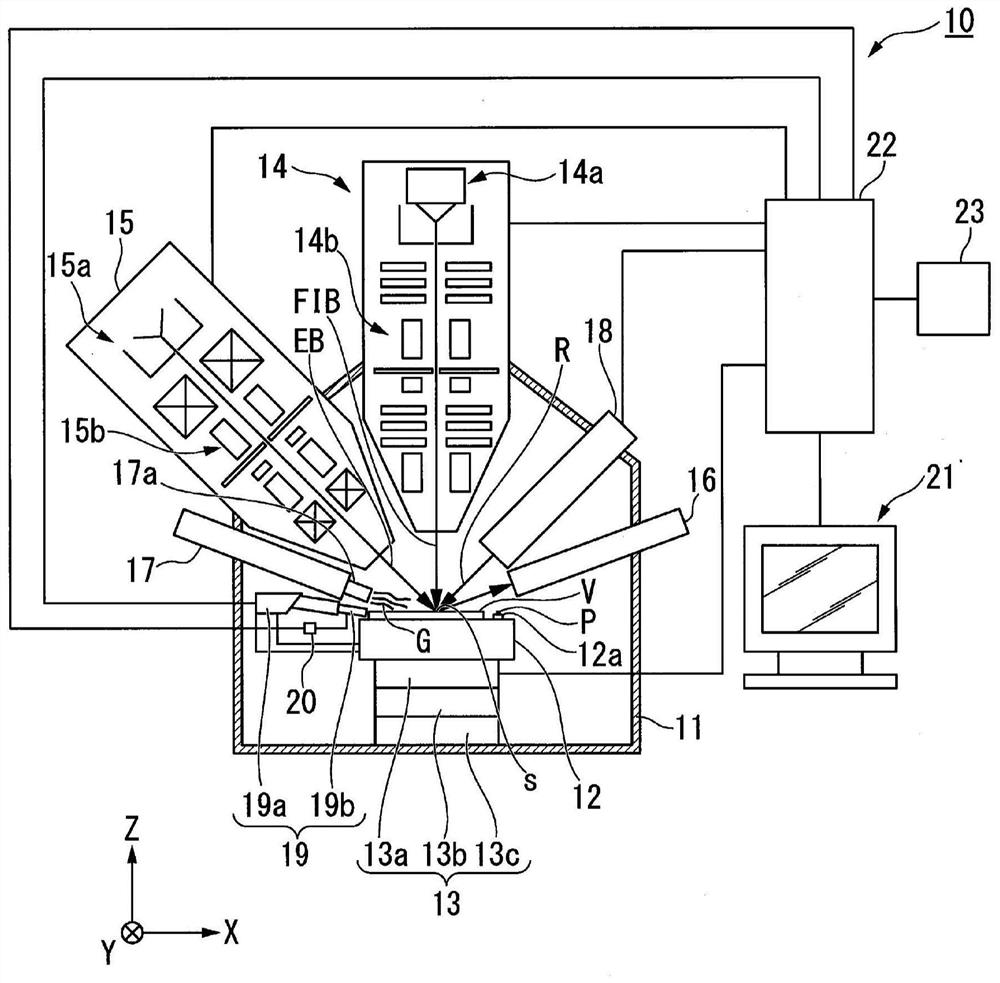

[0031] figure 1 It is a schematic configuration diagram showing a charged particle beam device according to an embodiment of the present invention.

[0032] Such as figure 1 As shown, the charged particle beam device 10 according to the embodiment of the present invention has: a sample chamber 11 capable of mainta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com