A continuous rice cooking and stewing machine

A cooking and stewing machine, rice technology, applied in steam cooking utensils, kitchen utensils, household utensils, etc., can solve the problems of small friction, affecting steamed rice, pot collision, etc., to achieve good taste, good cooking effect, and increased movement the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

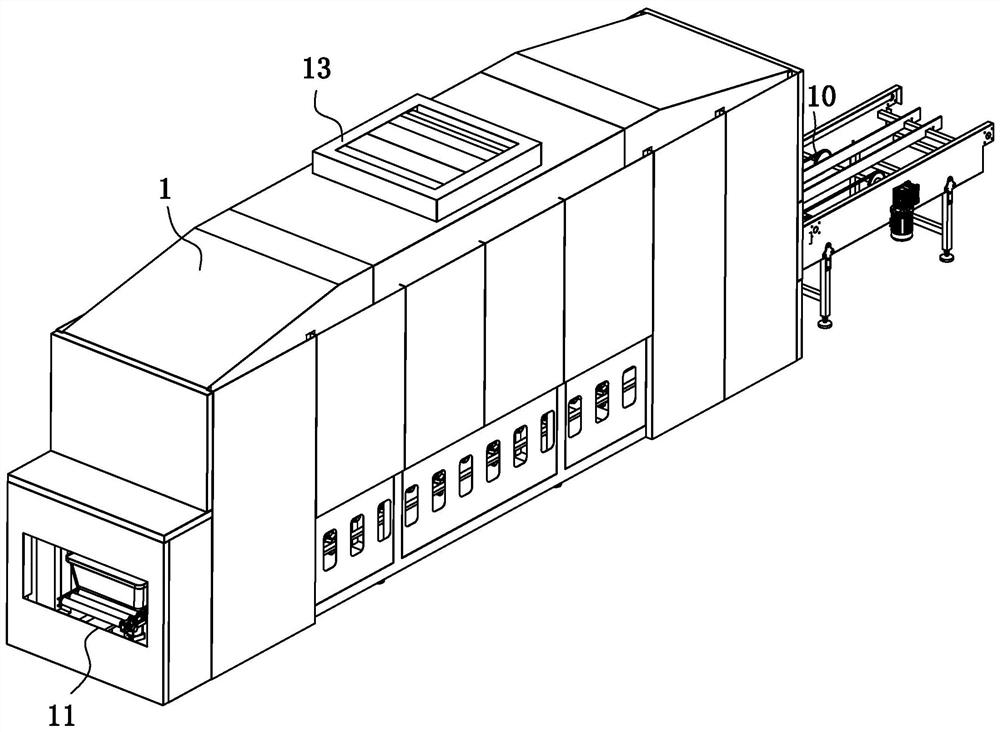

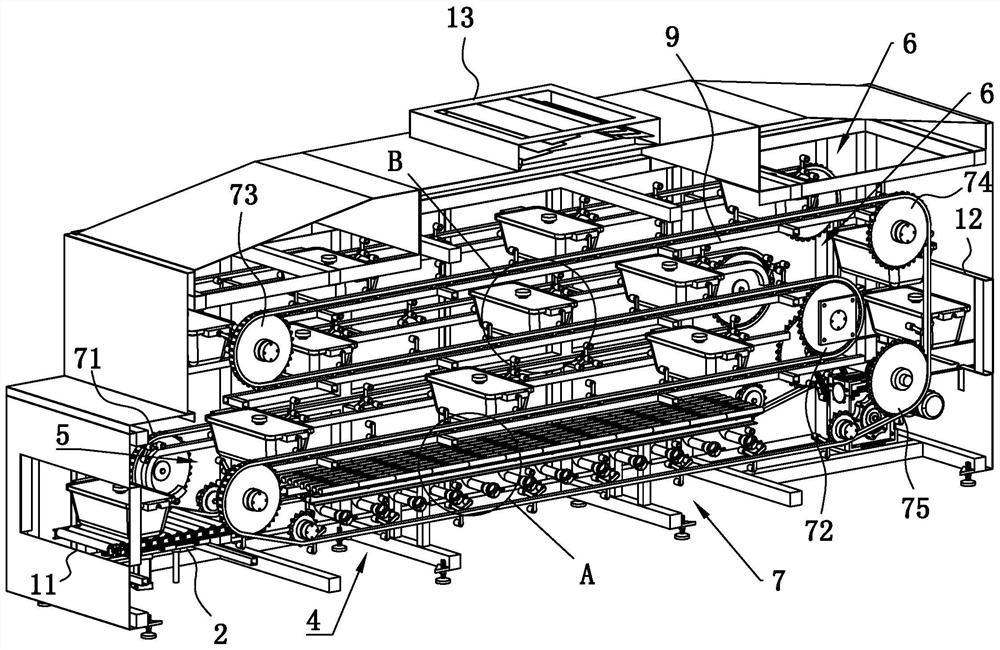

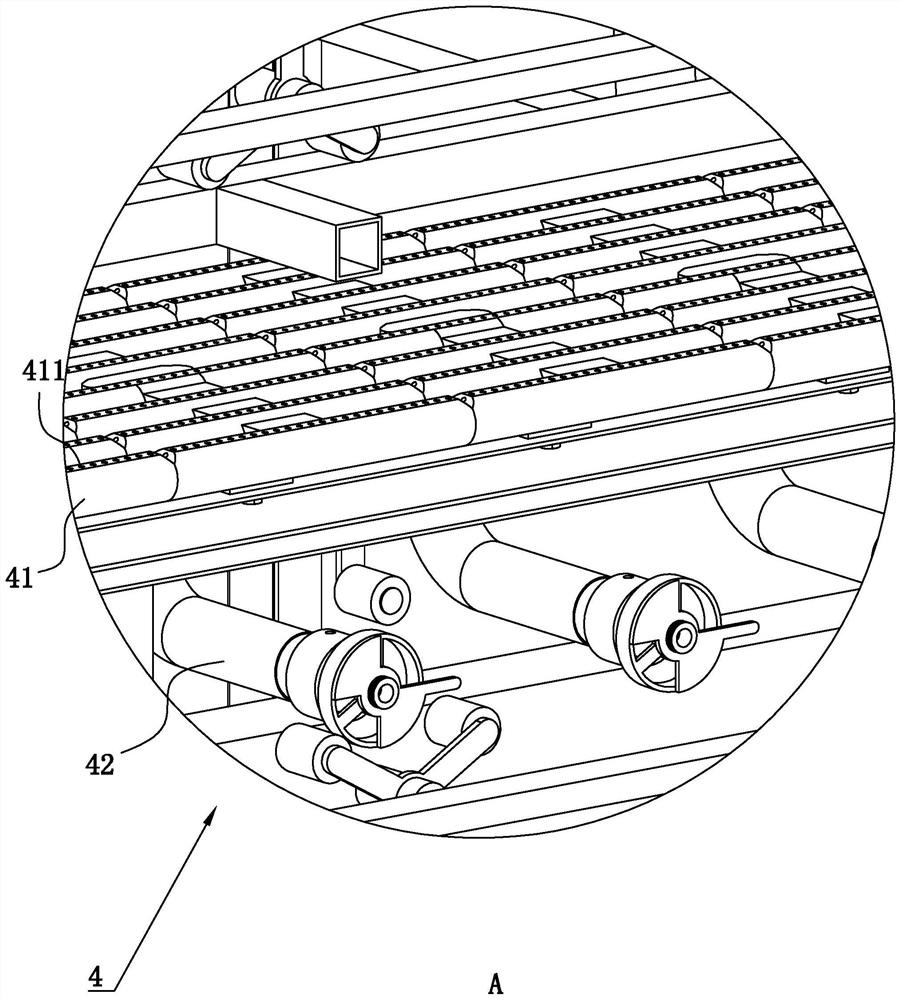

[0031] A continuous rice cooking and stewing machine, such as figure 1 and figure 2 As shown, it includes a rectangular cooking and stewing machine housing 1, the two sides of the cooking and stewing machine housing 1 are respectively provided with a rectangular inlet 11 and a rectangular outlet 12, and the cooking and stewing machine housing 1 is horizontally provided with a The first transfer device 2 in the stewing machine housing 1, the rectangular rice cooker 3 that needs to be steamed is placed on the first transfer device 2 (here as Figure 5 shown). A heating device 4, a rice steaming passage 5, and two rice stewing passages 6 are sequentially arranged in the housing 1 of the cooking and stewing machine from bottom to top. And the two inner sides of the cooking and stewing machine housing 1 are provided with a transmission device 7 that drives the rice cooker 3 to advance in the rice steaming passage 5 and the rice stewing passage 6 .

[0032] Such as figure 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com