Pneumatic glue gun assembly convenient to clean

A technology of glue guns and components, which is applied to the device for coating liquid on the surface, spraying device, coating, etc., which can solve the problems of easy changes, glue overflow, environmental pollution, etc., and achieve convenient timing, convenient disassembly and cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

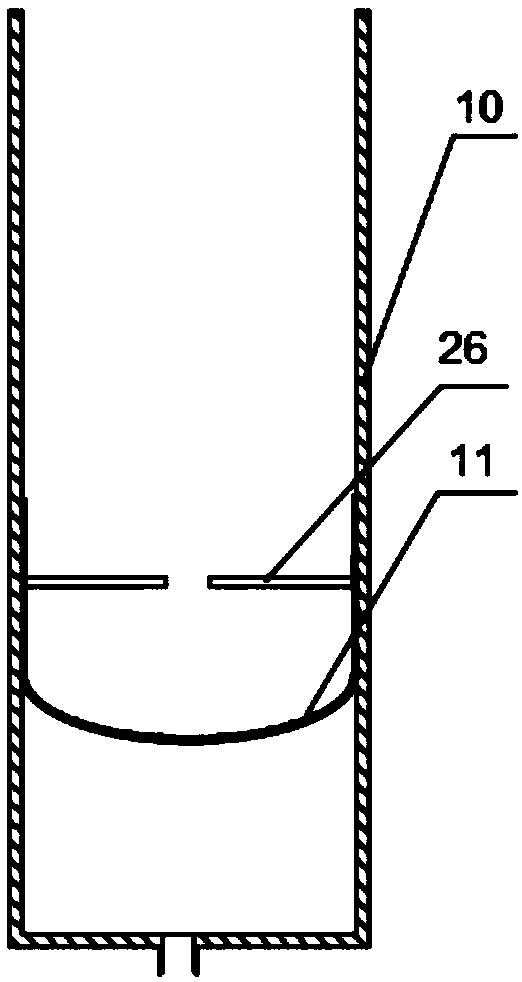

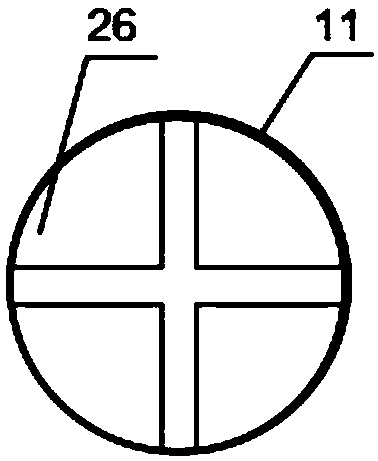

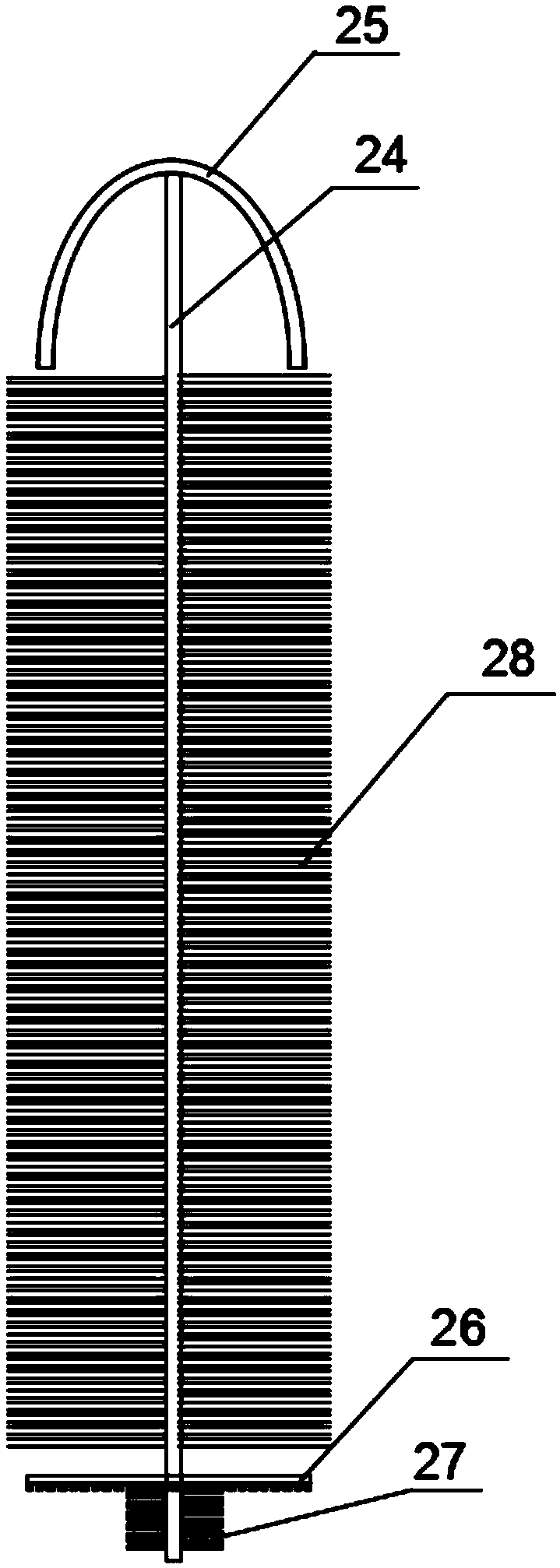

[0029] Such as Figures 1 to 4 As shown, a pneumatic glue gun assembly that is easy to clean includes a glue gun and a glue cartridge, and the glue gun includes a glue gun body 1, a glue gun handle 2, and a trigger 3; the front end of the glue gun body is provided with a front cover 4, and the rear end A rear end cover 5 is provided, and both the front end cover and the rear end cover are connected to the glue gun body through threads; the glue gun handle 2 is provided with an air inlet 6, and the glue gun handle 2 is provided with a valve that cooperates with the trigger 3 to control the on-off of the gas. Air valve mechanism 7; the air outlet 8 of the air valve mechanism 7 is connected to the joint on the rear end cover 5 through the glue gun air pipe 9; the rubber cartridge includes a rubber cylinder body 10, a piston 11, and a glue nozzle 12; the piston 11 A baffle 23 is arranged on the top, and the baffle 23 forms a cavity with the piston 11. The baffle 23 is also provide...

Embodiment 2

[0033] Compared with Embodiment 1, the glue gun assembly of this embodiment further includes a threaded plug 22 for sealing the glue outlet at the front end of the barrel 10 . The mouth of the tail of the barrel 10 is provided with external threads, and the glue gun assembly also includes a threaded sealing cover 21 for sealing the mouth of the tail.

[0034] The cylinder body of the rubber cartridge in this embodiment can be completely sealed by the rear sealing cover and the plug, can be heated and cooled, and will not leak glue or enter water. The schematic diagram of the rubber cartridge when sealing is as follows Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com