Deep cavity type hot extrusion mold for aluminum alloy joint members and preparation method thereof

A technology of hot extrusion dies and aluminum alloys, which is applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, low material utilization rate, and large amount of machining, and achieve high heating efficiency and small size. The effect of high precision and surface precision and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

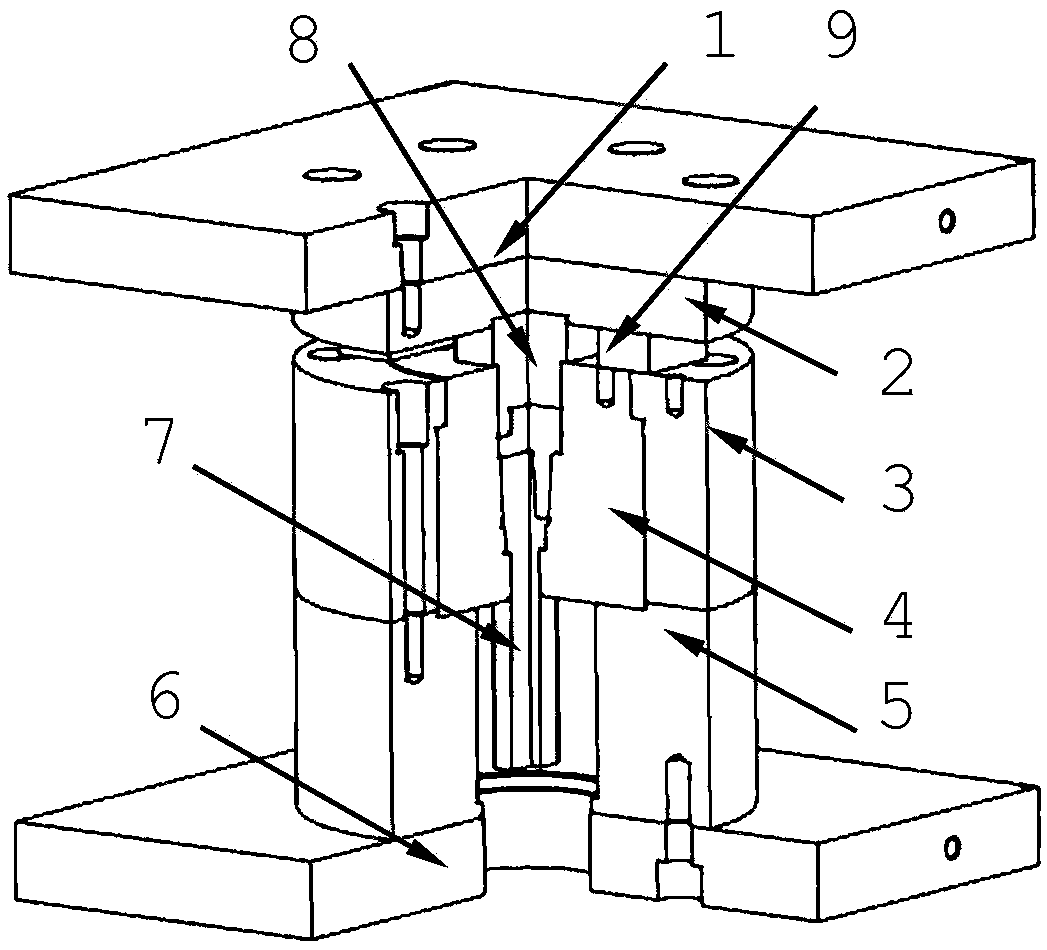

[0043] The technical problem to be solved by the present invention is: the present invention provides a deep-cavity hot extrusion forming die for aluminum alloy joint components and a preparation method thereof, which can effectively ensure high-efficiency hot extrusion forming of aluminum alloy joint components. A joint component such as Figure 11 As shown, the three-dimensional size is about 62×52×72mm.

[0044] The preferred embodiment of the present invention will be described in further detail below in conjunction with the accompanying drawings.

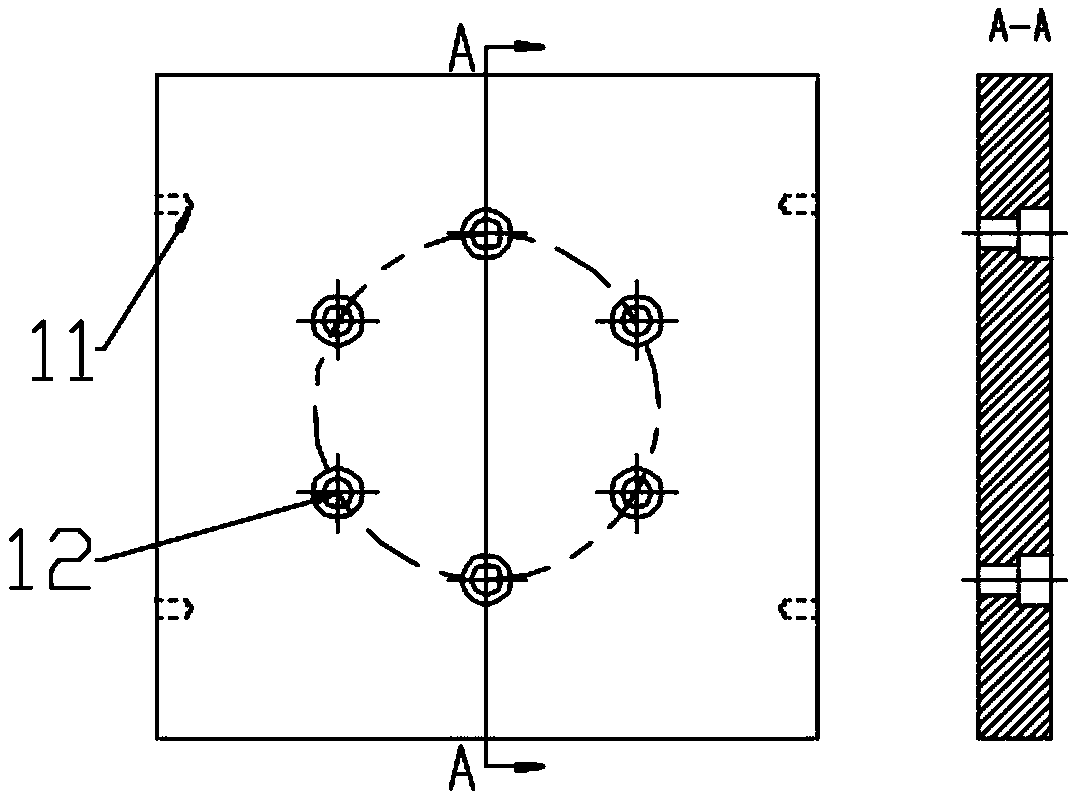

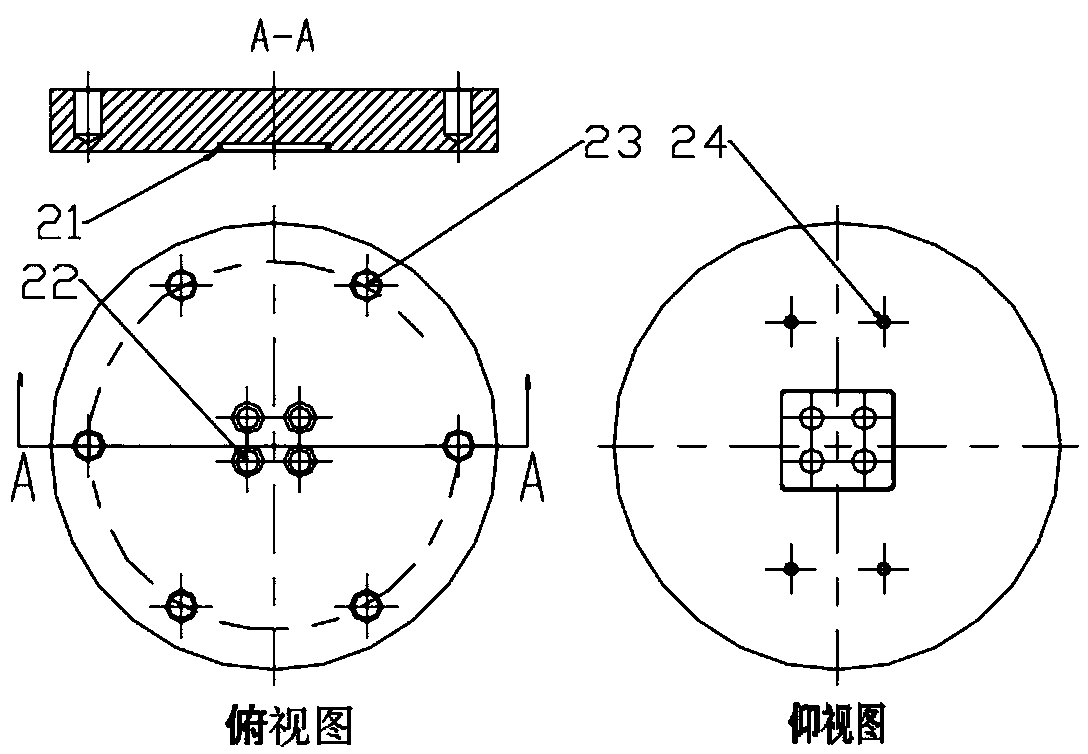

[0045] A deep-cavity hot extrusion die for aluminum alloy joint components, such as figure 1 As shown, it is characterized in that it includes: an upper template 1, a punch fixing plate 2, a stress ring 3, a die 4, a die backing plate 5, a lower template 6, a push rod 7, a punch 8, and a limit block 9; The upper mold 1, the punch fixing plate 2, the punch 8, and the limit block 9 are connected by bolts to form the upper mold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com