Cross sliding type automatic translation cutting device for artificial board

A translation device and wood-based panel technology, which is applied in the field of transverse-moving wood-based panel automatic translation section device, can solve the problems of vibration force, high labor intensity, poor section stability, etc., to avoid vibration or offset falling, The effect of improving the stability of the section and improving the cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

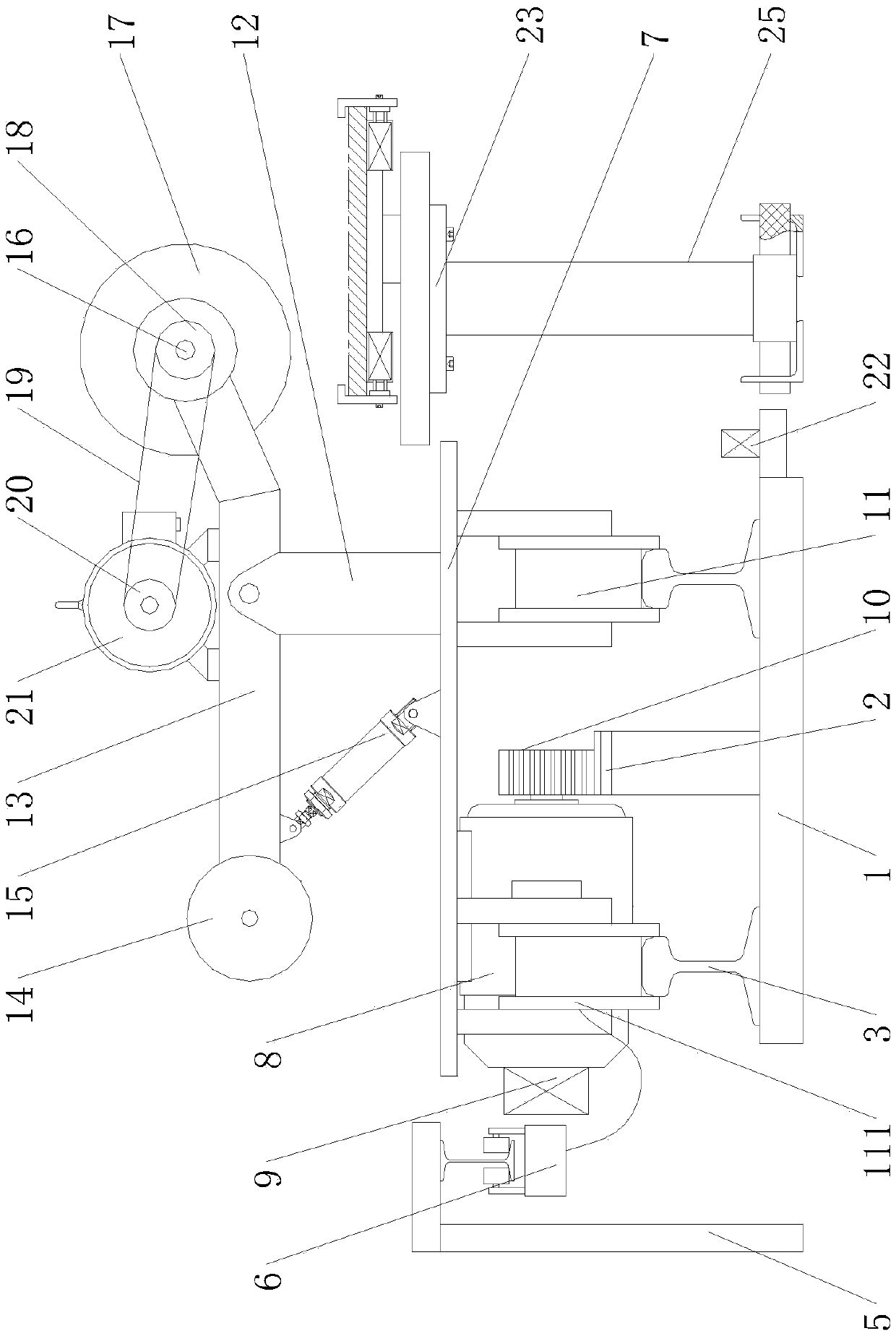

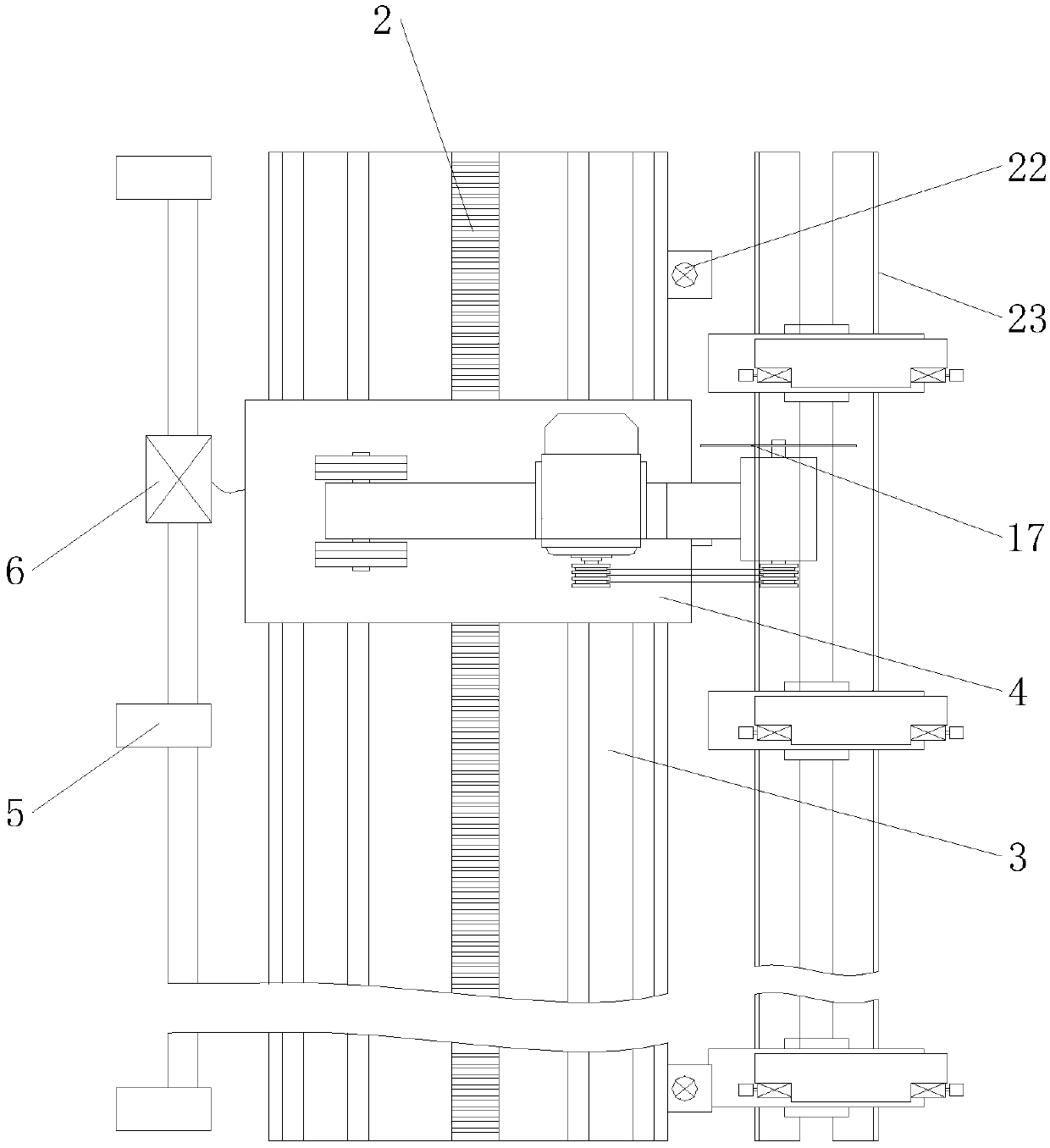

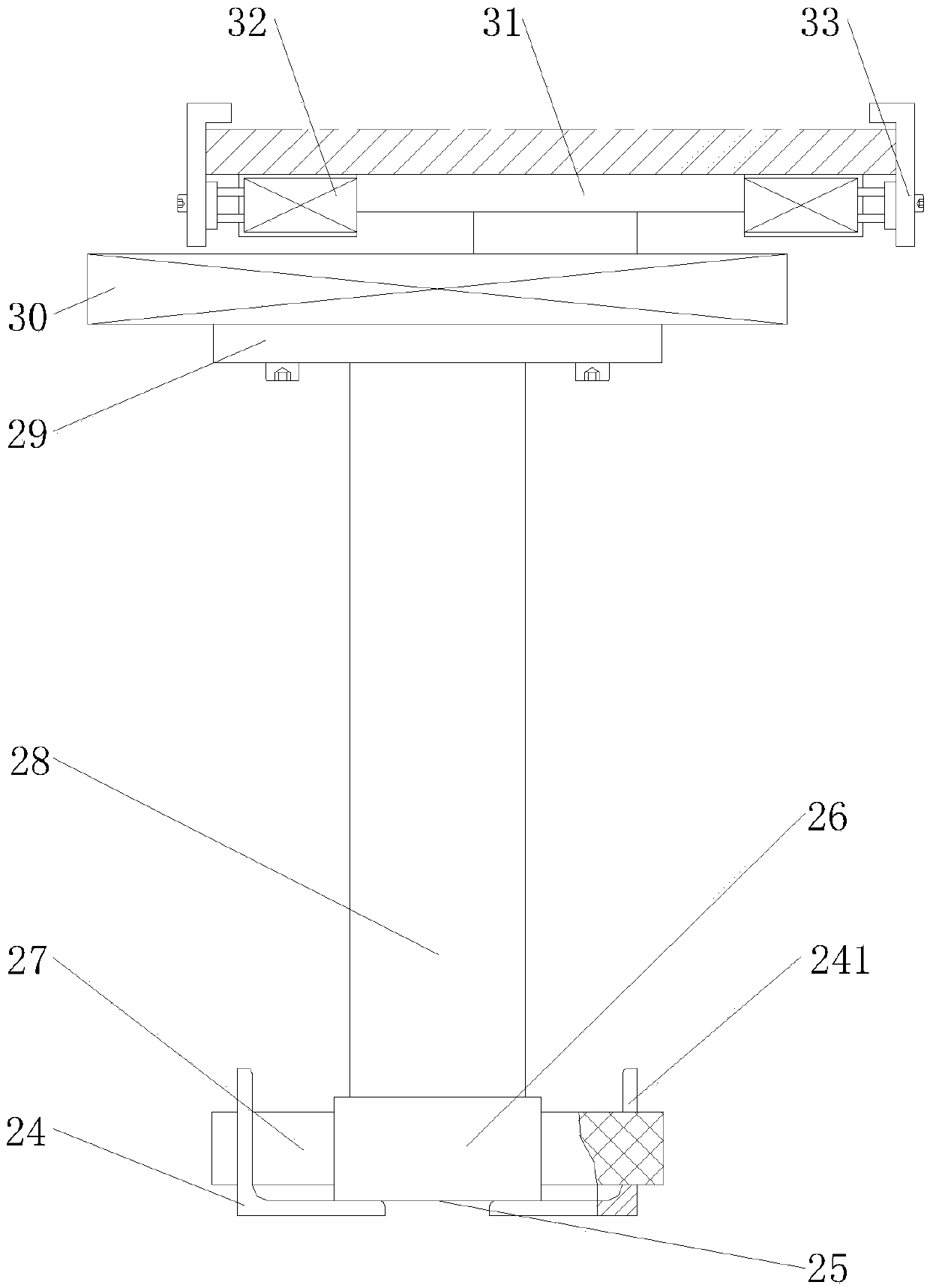

[0018] Example. A transverse-moving wood-based panel automatic translation section device, constituted as follows figure 1 As shown, including base plate 1, drive rack 2 is provided on base plate 1, light rail 3 is provided on both sides of drive rack 2, traverse section device 4 is provided on light rail 3, and base plate 1 side is provided with suspender 5 Cable slide frame 6; described traversing section device 4 comprises traversing platform 7, and the center of traversing platform 7 bottoms is provided with traversing motor 8, and traversing motor 8 is provided with encoder 9, and traversing motor 8 ends are provided with There is a driving gear 10 matched with the driving rack 2, a plurality of rollers 11 cooperating with the light rail 3 are arranged around the traversing motor 8, a bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com