Dasheen automatic slitter

A strip cutting machine and taro technology, applied in metal processing, etc., can solve the problems of high use cost, inconvenient replacement, easy hand injury, etc., achieve high processing efficiency and reduce pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

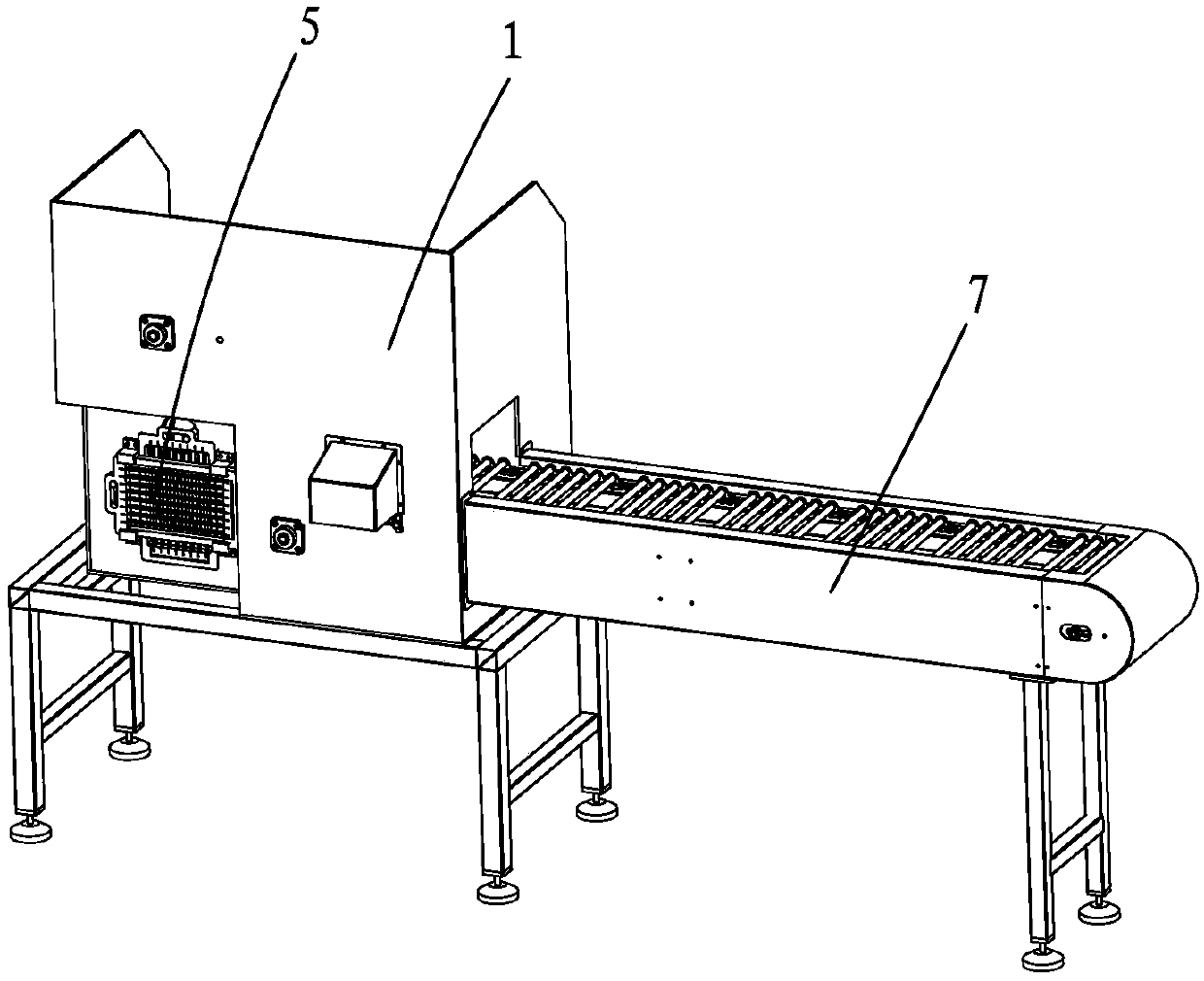

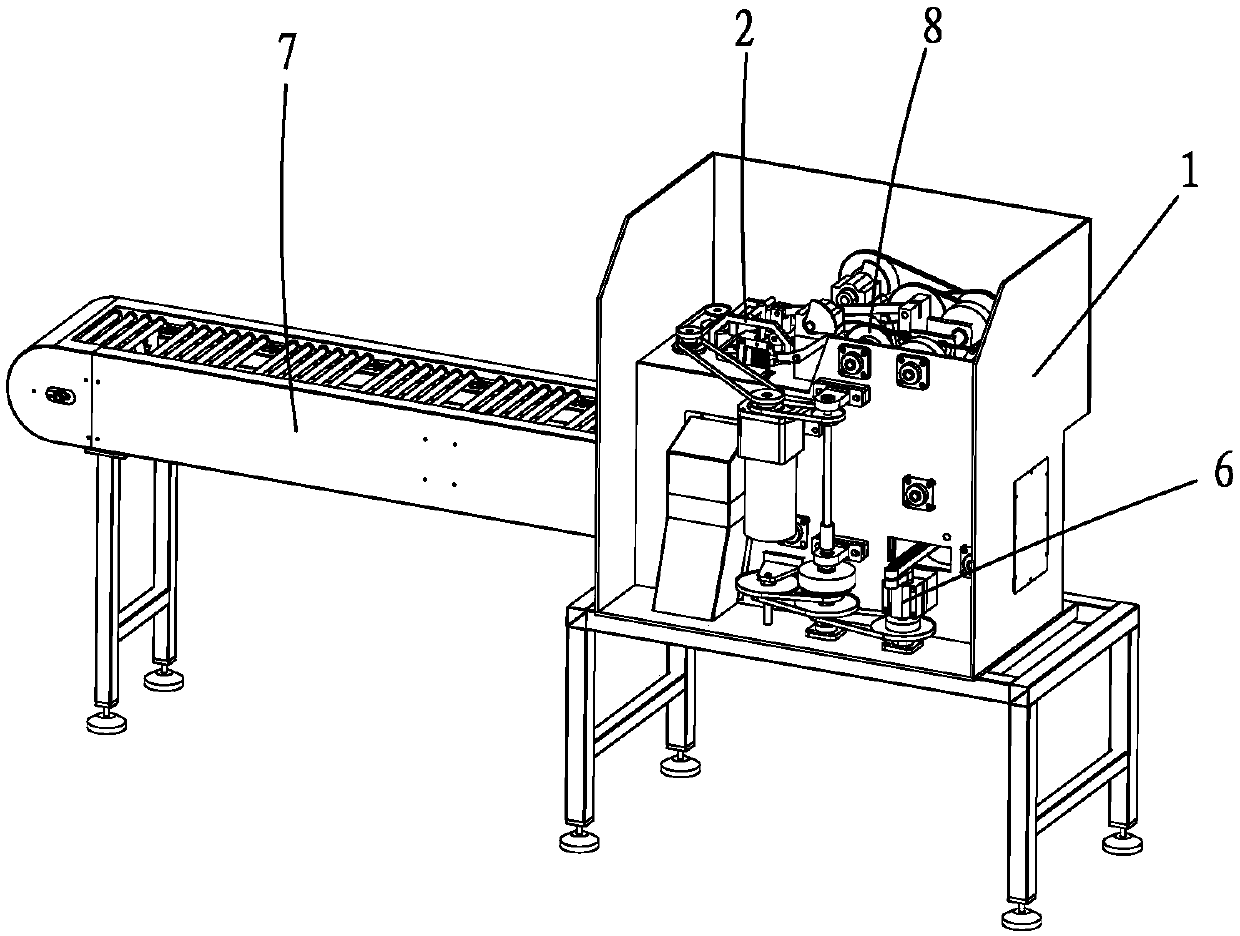

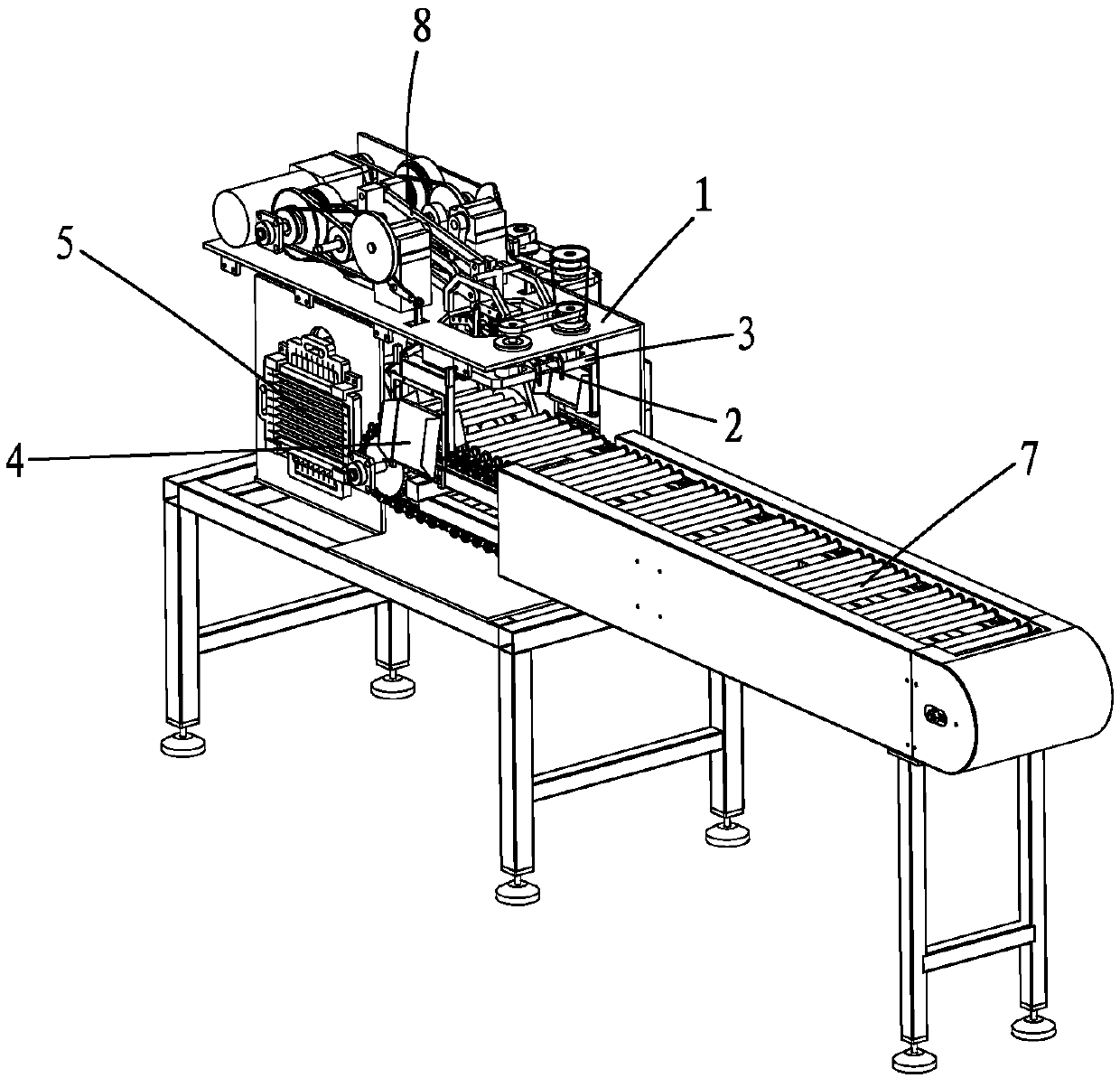

[0039] refer to Figure 1 to Figure 7 , a taro automatic cutting machine, comprising a frame 1, a manipulator 2, a first cutting mechanism 3, a collection mechanism 4, a second cutting mechanism 5, a pushing mechanism 6 and a feeding mechanism 7, and the manipulator 2 can grab taro , the first cutting mechanism 3 can cut taro tailings, the collection mechanism 4 can recycle taro tailings, and the second cutting mechanism 5 can cut taro into strips;

[0040] The manipulator 2 includes an L-shaped base 21, two gripping arms 22 and four poles 23, and each gripping arm 22 includes two grabbing bars 221 and a plurality of first chain bars 222, and the two gripping arms Rod 221 is symmetrically connected to the two ends of each first chain rod 222, like this, when clamping arm 22 is clamping taro, the distance between the first chain rod 222 can expand the contact between clamping arm 22 and taro surface, the clamping is firm, and it can also reduce the air resistance that the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com