Special steel wire rope for elevator compound hoisting belt

A technology of steel wire rope and hoisting belt, which is applied in the field of elevator composite hoisting belt, can solve the problems of low fatigue resistance and low service life, and achieve the effects of low cost, guaranteeing adhesion stability and reducing process complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

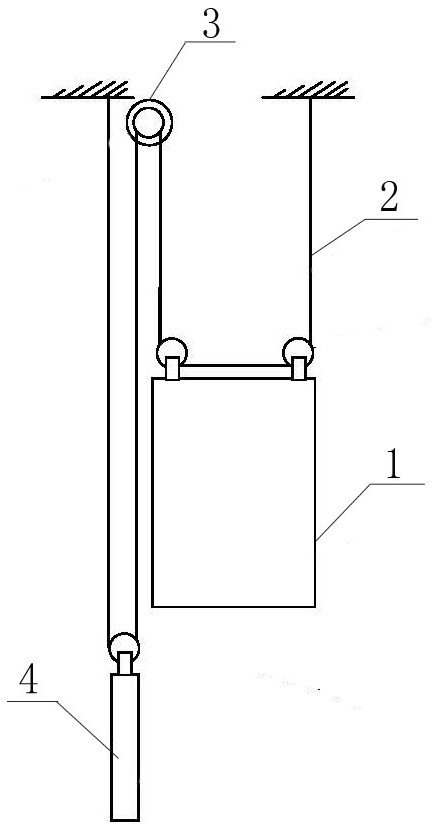

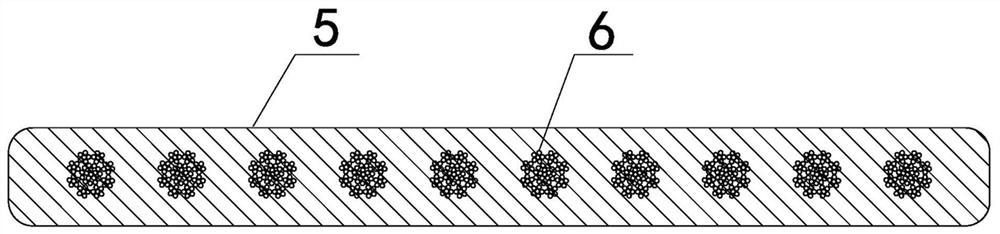

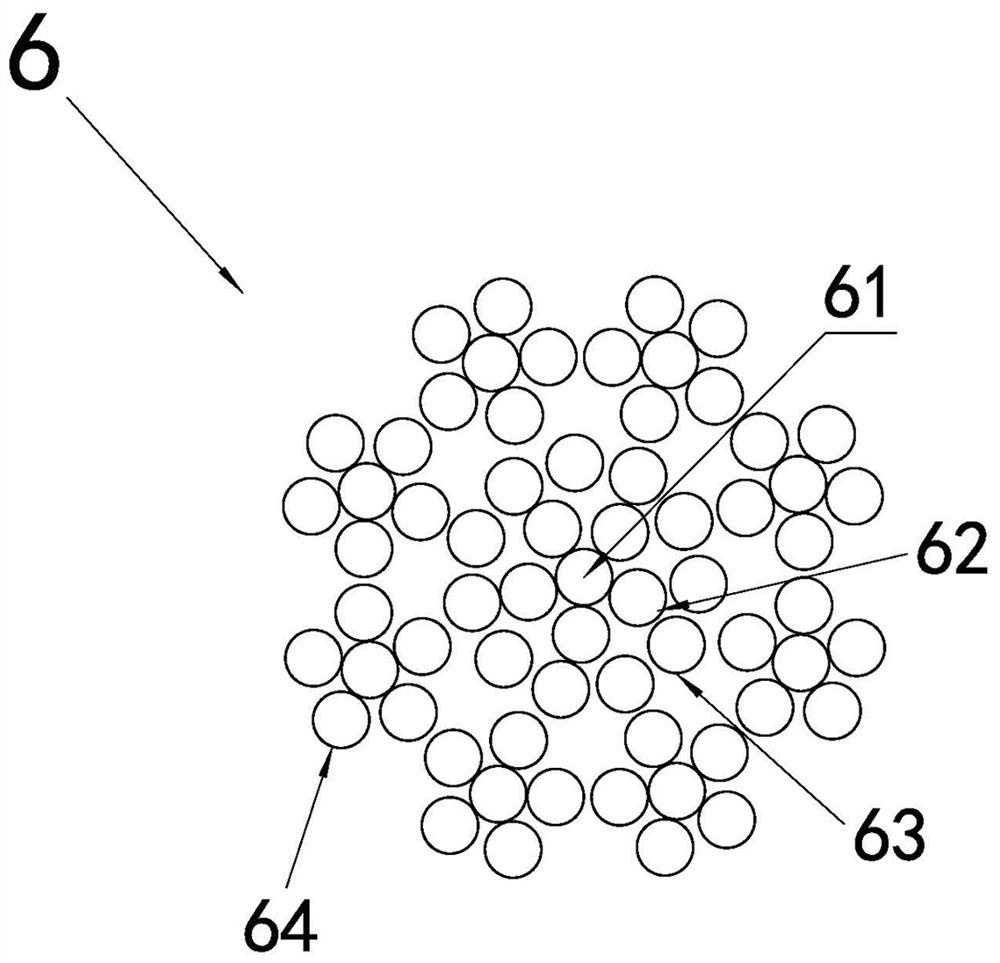

[0019] To make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, below in conjunction with the attached Figure 1 ~ Figure 4 The present invention will be further described in detail with specific embodiments.

[0020] The elevator composite hoisting belt adopted in this embodiment is installed in the elevator hoisting mechanism, such as figure 1 As shown, the elevator hoisting mechanism is mainly composed of a composite lifting medium 2 connecting a car 1 and a counterweight 4 through a traction machine 3 . The composite lifting medium 2 is a flat strip, such as figure 2 As shown, in the elevator hoisting mechanism, one side of the surface is attached to the traction machine 3, and the rotation of the traction machine 3 is converted into the linear motion of the composite lifting medium 2 through friction with the composite lifting medium 2, and then the traction force is transmitted to The car 1 realizes the li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com