A post-pouring belt and its construction method

A post-casting belt and screw technology, which is applied in the fields of formwork/template/work frame, building components on-site preparation, construction, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

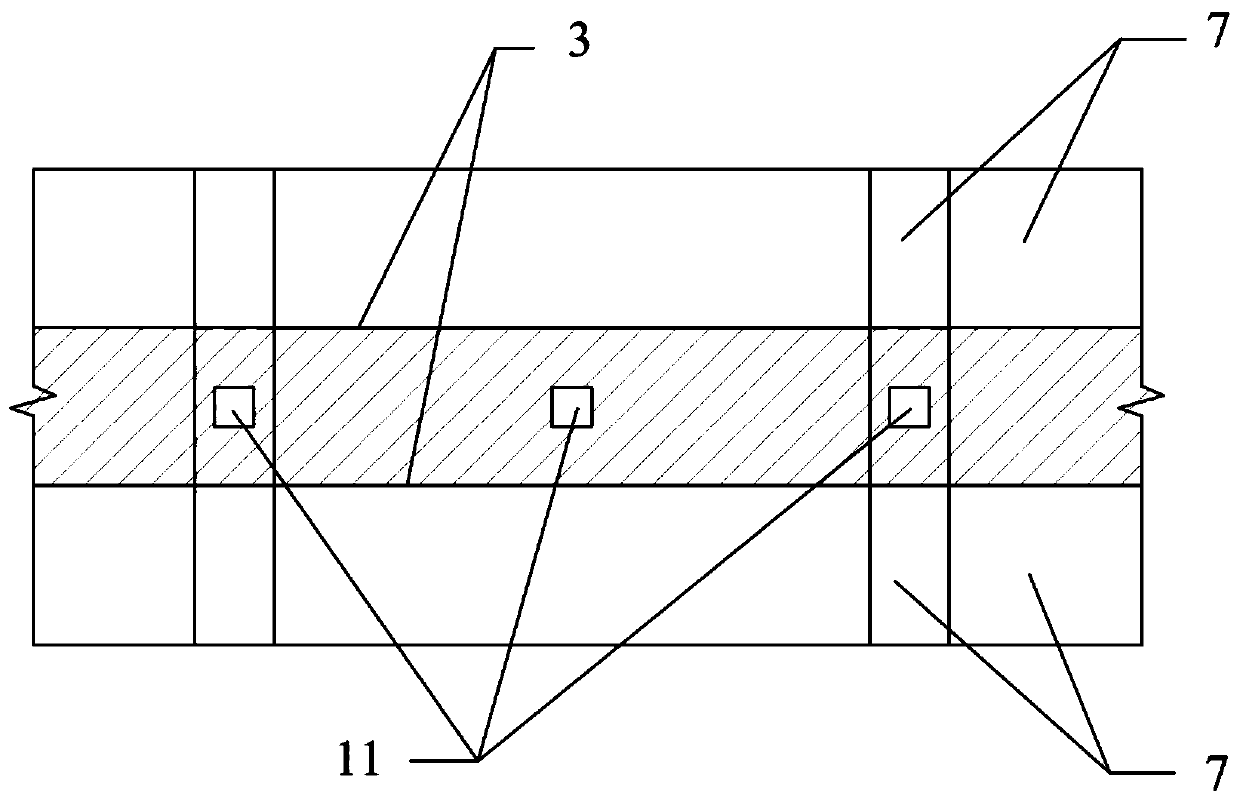

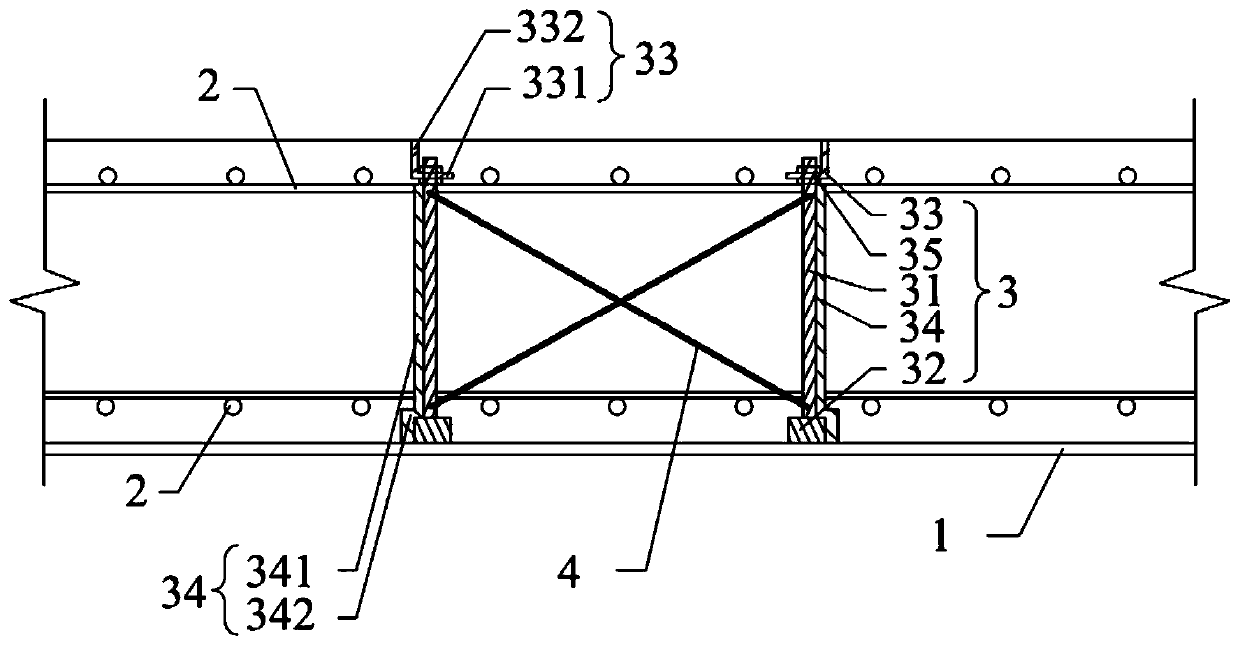

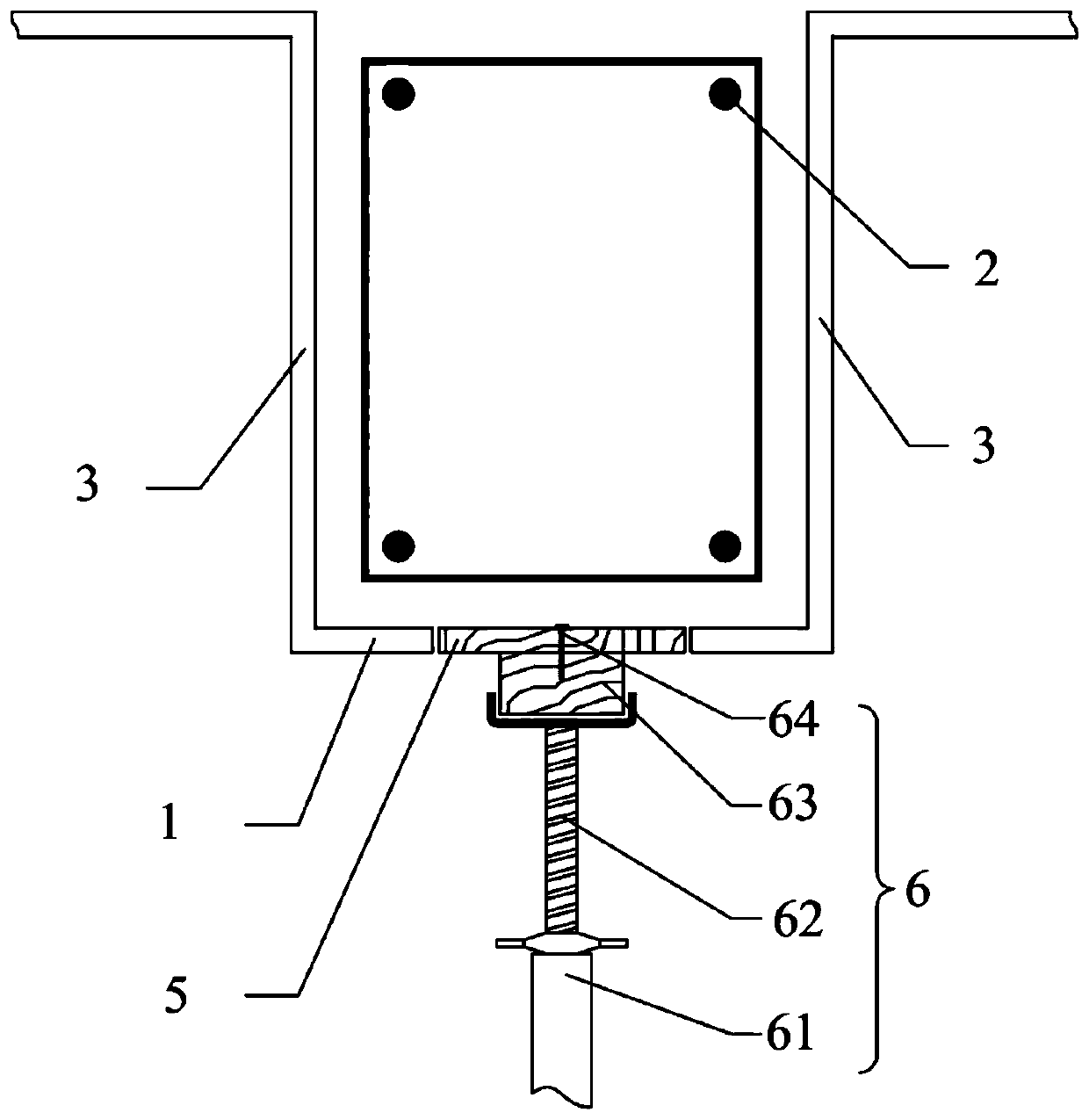

[0042] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0043] Such as Figure 1~3 As shown, the present embodiment provides a post-casting belt, which includes a bottom formwork 1, a reinforcement frame 2 and a side form 3, and two layers of reinforcement frames 2 are arranged at intervals above the bottom formwork 1, and the reinforcement frame 2 includes horizontally spaced A plurality of steel bars and a plurality of steel bars arranged at longitudinal intervals, the junctions of the horizontal steel bars and the longitudinal steel bars are tied tightly with wires, the steel bar skeleton 2 of each layer is parallel to the horizontal plane, and the two side forms 3 are arranged oppositely, and the bottoms of which are all connected to the bottom Template 1 abutment. In this embodiment, the bottom formwork 1 includes a beam formwork and a slab formwor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com