Anti-impact tubular heat exchanger

A tube heat exchanger, anti-shock technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problem of unable to adjust the flow rate of the tube bundle, and achieve the effect of avoiding direct erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

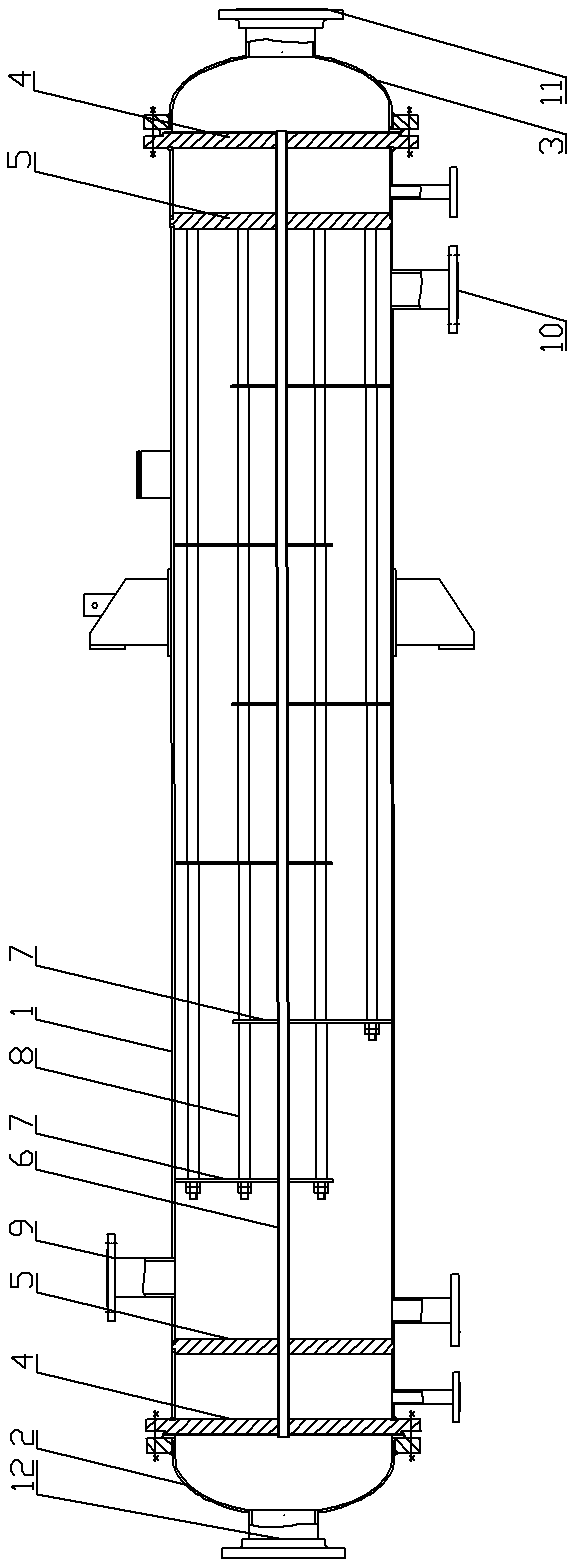

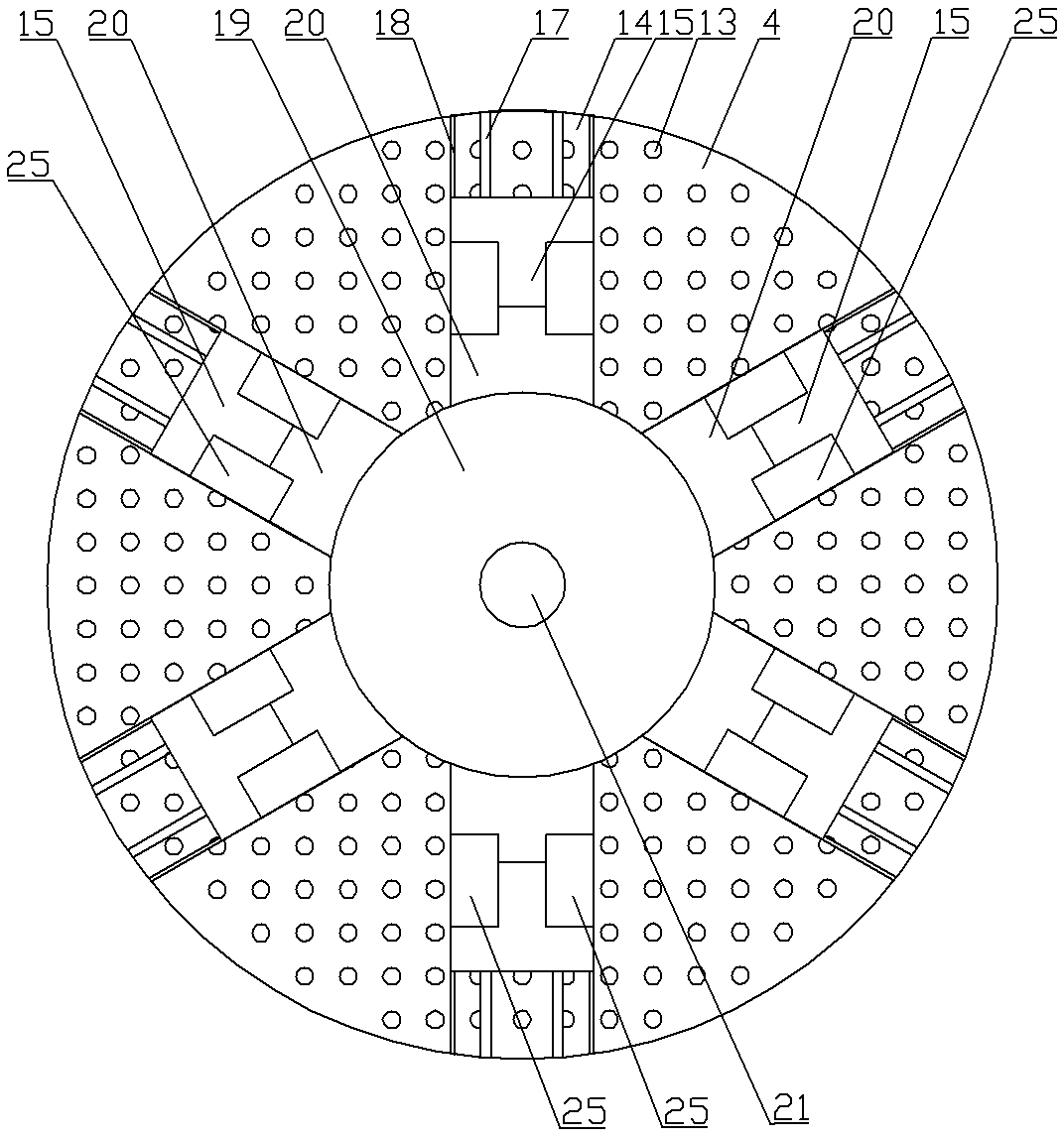

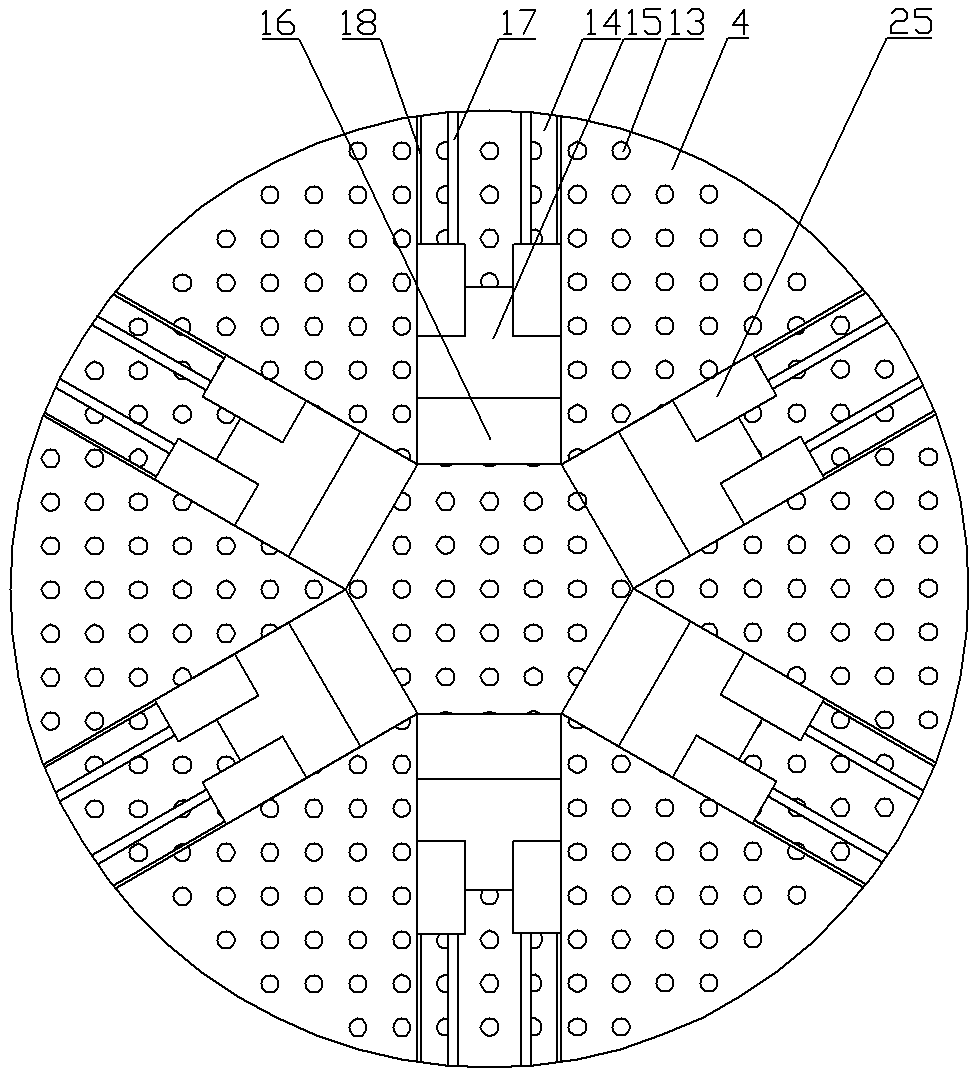

[0016] An anti-impact tubular heat exchanger, which includes a shell, a tube bundle, a tube sheet and a head. The structure of this part is the same as that of the existing tubular heat exchanger. Please refer to figure 1 , the two ends of the shell 1 are installed with heads 2 and 3 respectively, and the outer tube plate 4 is arranged between the heads 2 and 3 and the shell 1, and the inner tube plate 5 can be formed between the outer tube plate 4 and the shell 1. In the anti-leakage chamber, the tube bundle 6 (only one is shown in the figure) runs through the shell and its two ends are respectively supported on the outer tube plate 4, and 13 is the tube bundle installation hole set on the outer tube plate 4. The improvement lies in ,Such as figure 2 , image 3 and Figure 4 As shown, a tube bundle flow regulating mechanism is provided on the outer tube sheet 4 adjacent to the head 3 provided with the tube side inlet 11a. The tube bundle flow regulating mechanism includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com