Method for obtaining optimal heating curve of low-carbon steel

A heating curve, low carbon steel technology, applied in instruments, data processing applications, forecasting, etc., can solve problems such as high cost and little production guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

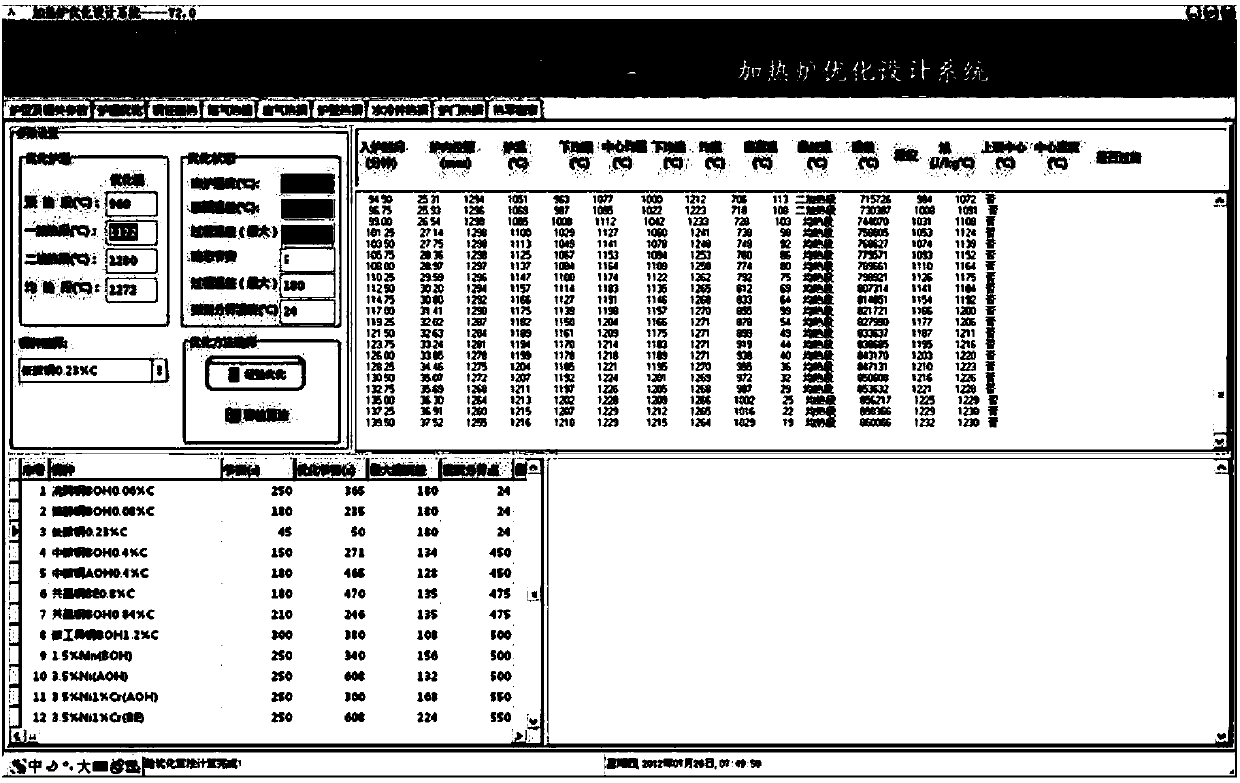

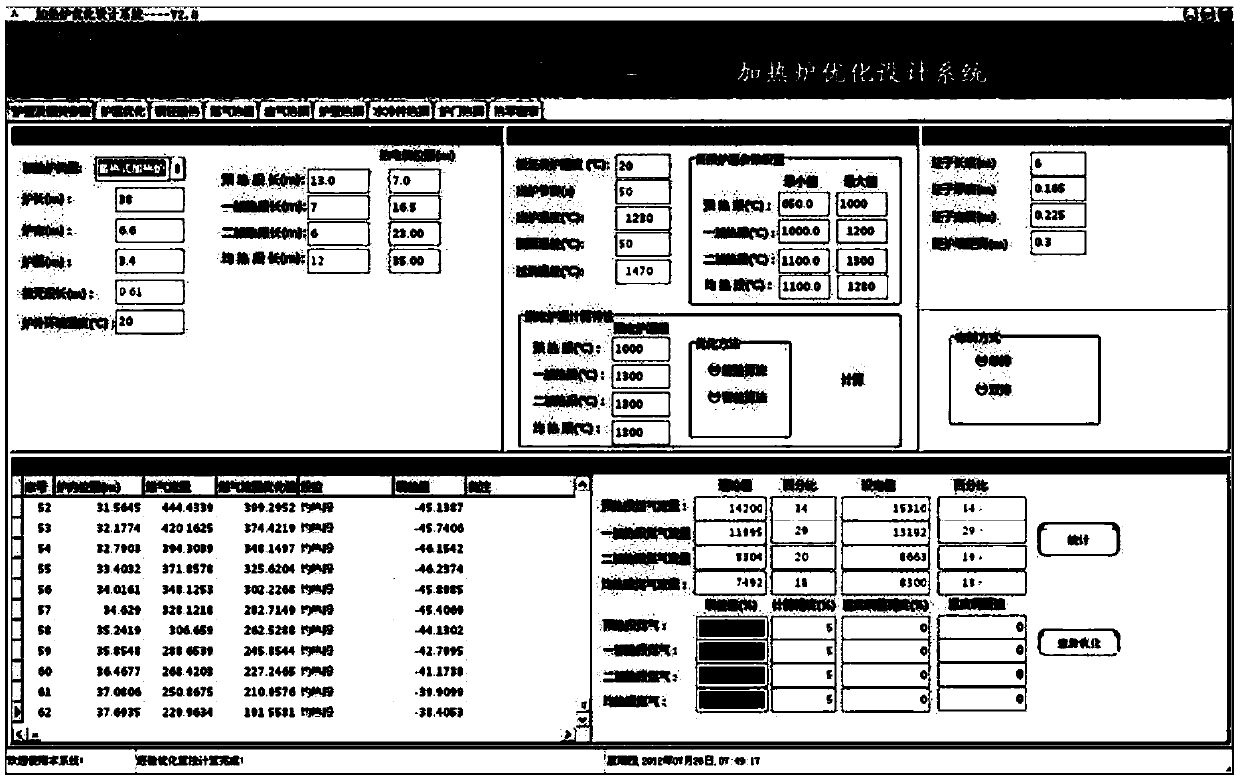

[0125] The present invention is described in further detail now in conjunction with accompanying drawing.

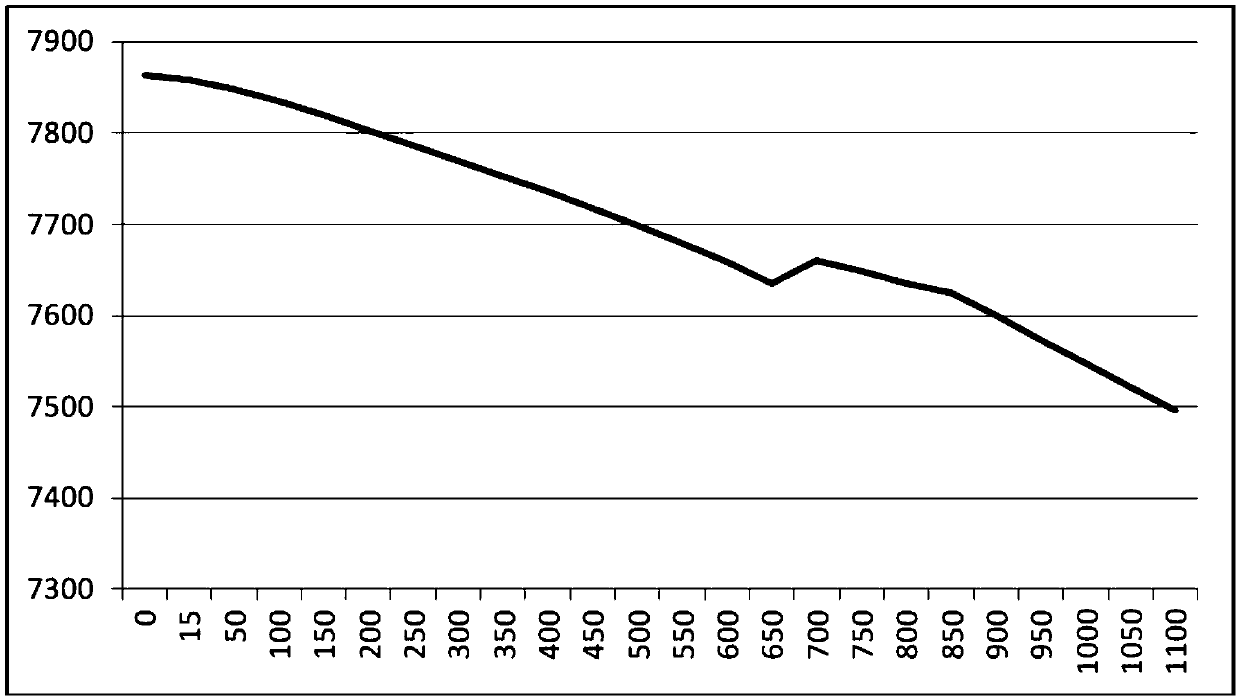

[0126] according to Figure 1 to Figure 12 A method for obtaining the optimal heating curve of low-carbon steel is shown, comprising the following steps:

[0127] Step 1: Collect the parameters of the billet type, fuel type and furnace structure of the steel rolling heating furnace, and set the minimum rhythm;

[0128] Specifically, the billet type is the billet composition (Table 1), and the density, heat capacity (Table 2, Table 3), thermal conductivity (Table 4) of the steel grade of the billet at each temperature, the composition of the fuel, Low calorific value, theoretical air, theoretical flue gas, smoke ratio to coal air, etc.;

[0129]Step 2: Establish a comprehensive balance model of the steel rolling heating furnace with the rolling start temperature as the target, divide the heating furnace into multiple micro-elements, and calculate the heat balance of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com