Solid solution heat treatment furnace

A technology of solution heat treatment and heat treatment furnace, applied in the direction of heat treatment equipment, furnace, furnace type, etc., can solve the problems of increasing equipment cost, energy waste, low thermal efficiency, etc., and achieve the effect of reducing heat loss, ensuring thermal efficiency, and reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

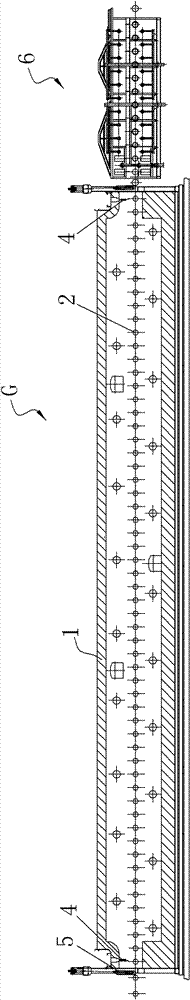

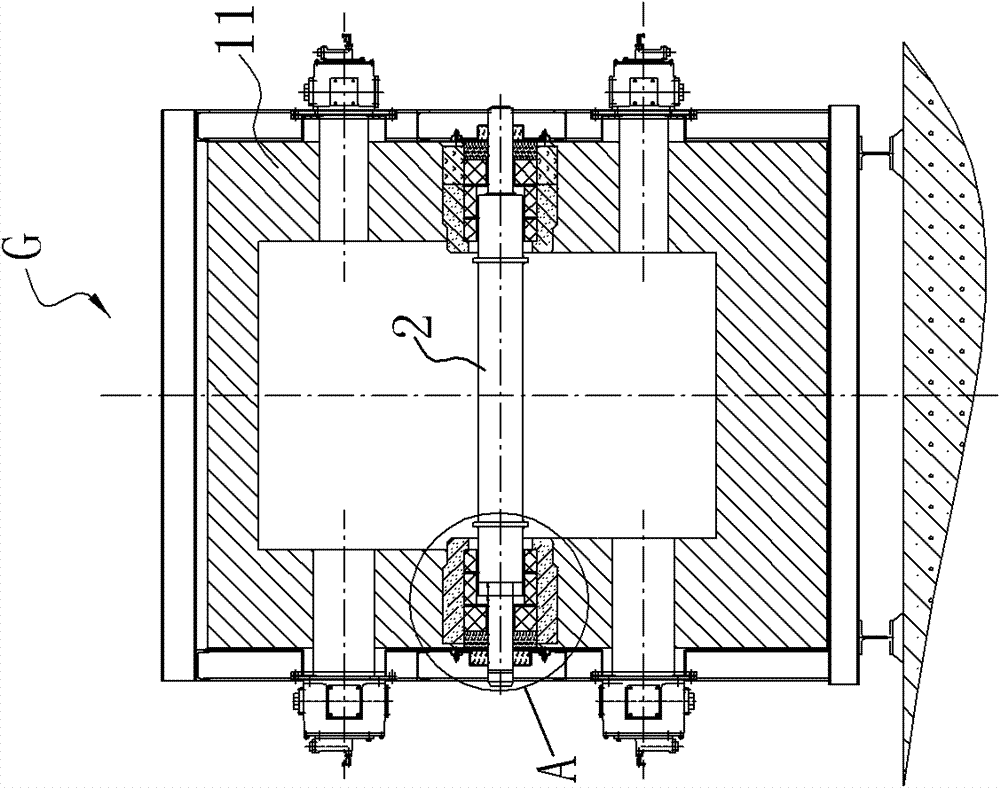

[0027] Please refer to figure 1 and figure 2 As shown, the solid solution heat treatment furnace according to the embodiment of the present invention includes a roller hearth heat treatment furnace G and a quenching machine 6 connected to each other. The roller hearth heat treatment furnace G includes a furnace body 1 and a plurality of furnace roller devices 2. Furnace walls 11 are arranged around the furnace body 1, and furnace body feeders are respectively arranged on opposite sides of the furnace body 1. Port and furnace body discharge port; a plurality of furnace roller devices 2 are arranged in parallel between the furnace body feed port and the furnace body discharge port, and the two ends of each furnace roller device 2 are sealed and arranged on the furnace body through the sealing module 3 In the wall 11, each furnace roller device 2 includes a water-cooled support shaft 21 and a roll body 22, and the water-cooled support shaft 21 is provided with a cooling water c...

Embodiment approach 2

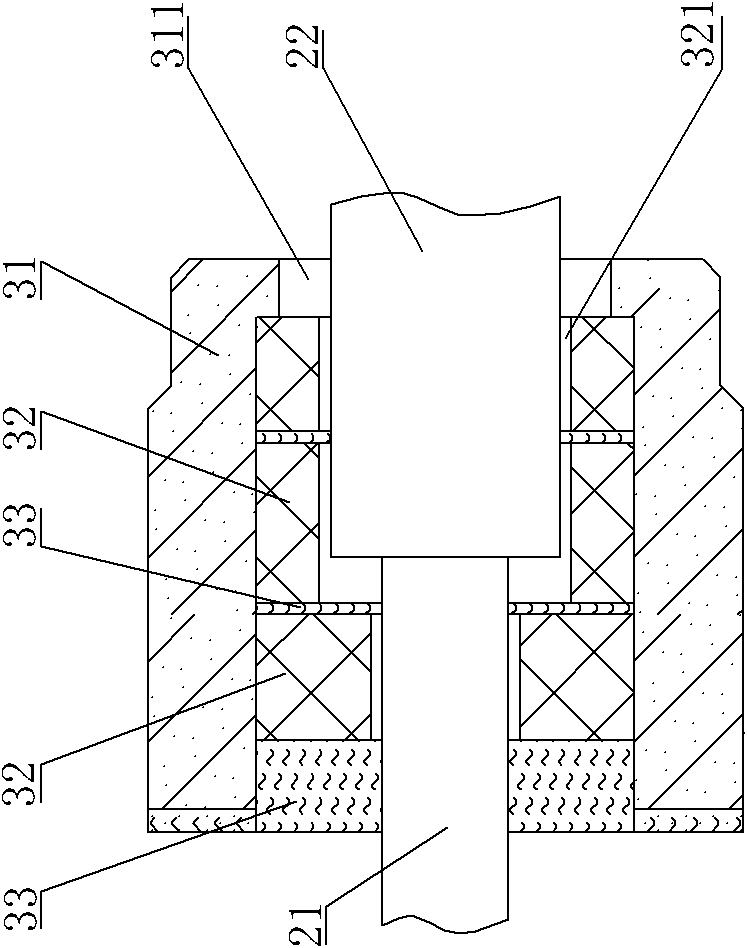

[0043] see figure 2 and Figure 4 As shown, the embodiment of the invention relates to a sealing module 3 .

[0044] The sealing module 3 includes a sealing brick 31, the sealing brick 31 has a through hole 311, and a multi-layer fiber module 32 is arranged in the axial direction in the through hole 311, and the end of the furnace roller device 2 is pierced through the In the multi-layer fiber module 32, a fiber blanket 33 is provided at the end of the furnace roller device 2 passing through the sealing brick 31, and the fiber blanket 33 is sealed between the sealing brick 31 and the furnace roller. between the ends of the device.

[0045] Specifically, the inner opening of the sealing brick 31 is in the shape of a cylinder, and it is fixedly arranged in the furnace wall 11 of the roller hearth heat treatment furnace G. The through hole 311 is provided at the center of the sealing brick 31, and the end of the furnace roller device 2 penetrates into the through hole 311 of ...

Embodiment approach 3

[0054] see Figure 5 to Figure 7A As shown, the embodiment of the invention relates to a quenching machine 6 .

[0055] see Figure 6 and Figure 7 As shown, the quenching machine of the embodiment of the present invention includes a casing 61, and the two sides of the casing are respectively provided with a material inlet and a material outlet correspondingly, and a plurality of parallel Quenching roller table 62, the two shaft ends of each quenching roller table 62 are respectively connected on the casing 61, there are at least two cooling sections along the arrangement direction of the roller table in the casing 61, the first cooling section L1 is water-cooled and The air-cooled cooling section, the second cooling section L2 is a water-cooled cooling section; the bottom of the casing 61 is provided with a drainage system 63 , and the drainage system 63 is located below the roller table 1 .

[0056] It is suitable for stainless steel or heat-resistant alloy steel and othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com