Cake placing device for continuous heat preservation

A cake, horizontally placed technology, applied in the direction of heat treatment and storage, can solve the problem of inability to keep the cake warm, achieve the effect of uniform heating and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

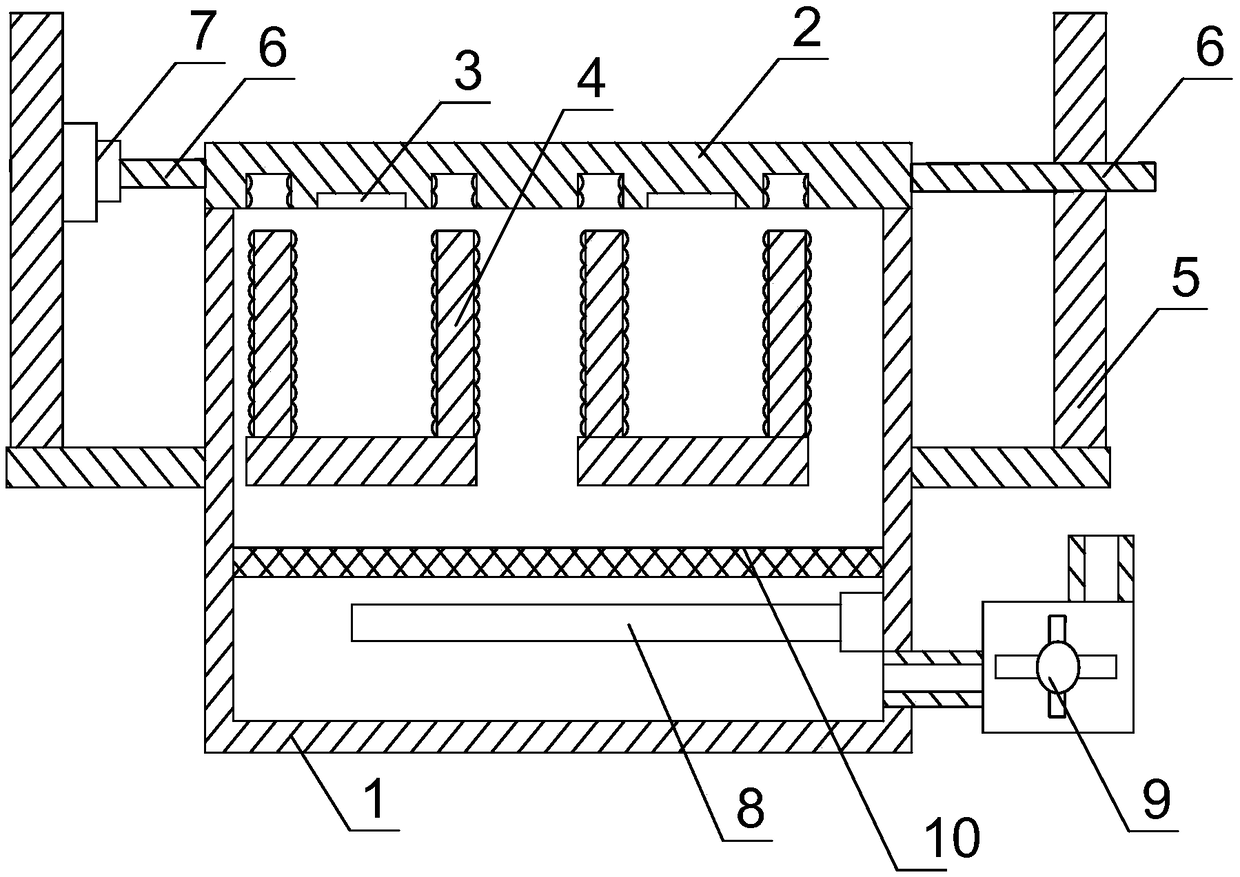

[0022] Such as figure 1 As shown, the cake placement device for continuous heat preservation of the present invention includes a box body 1 with a fully open top surface, a heating device is installed inside the box body 1, and a horizontal plate 2 placed horizontally is arranged above the box body 1. The horizontal plate 2 is placed on the top surface of the box body 1, the opening of the top surface of the box body 1 is completely covered by the horizontal plate 2, and a plurality of grooves 3 for placing cakes are arranged on one surface of the horizontal plate 2, and the horizontal plate 2 is provided with A plurality of outer covers 4 corresponding to the number of the grooves 3, the outer covers 4 are heat-conducting covers, the outer covers 4 correspond to the grooves 3 and are located on the same board surface of the horizontal plate 2, and the cakes placed in the grooves 3 are wrapped in In the corresponding outer cover 4, the outer cover 4 and the horizontal plate 2 ...

Embodiment 2

[0025] Based on Embodiment 1, both sides of the horizontal plate 2 are respectively connected with vertically placed telescopic rods 5, the side wall of the horizontal plate 2 is connected with the telescopic rod 5 on the same side through a horizontally placed rotating shaft 6, and the rotating shaft 6 on one side of the horizontal plate 2 Pass through the telescopic rod 5 on the same side and rotate with the telescopic rod 5, the rotating shaft 6 on the other side of the horizontal plate 2 is connected and fixed with the telescopic rod 5 through the motor 7, and the telescopic rods 5 on both sides of the horizontal plate 2 are fixed on the box body 1 on the side wall.

[0026] The horizontal plate is directly placed on the top surface of the box body, and it is very inconvenient to turn over the horizontal plate. The invention realizes the turning of the horizontal plate by using the telescopic rod, the motor and the rotating shaft. Jack it up, turn on the motor, the motor d...

Embodiment 3

[0028] Based on the above-mentioned embodiment, the heating device inside the box body 1 includes a plurality of heating pipes 8, and the heating pipes 8 are placed horizontally inside the box body 1. A fan 9 is connected to the side wall of the box body 1 below the heating pipes 8, and the fan 9 is located in the box body. Outside the body 1 , the air outlet of the fan 9 communicates with the inside of the box body 1 . A partition plate 10 placed horizontally is installed inside the box body 1. The partition plate 10 is located above the heating pipe 8. The partition plate 10 is sealed and connected with the inner wall of the box body 1. The partition plate 10 is a filter plate. The heating pipe cooperates with the fan to evenly heat the inside of the box. The fan ventilates the box. The air body flows upwards and passes through the heating tube. Carry out heat preservation, the heating device of the present invention heats evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com