Dedusting hopper of screw extruder

A technology of screw extruder and hopper, which is applied in the field of dust removal hopper of screw extruder, which can solve the problems of poor dust removal effect and easy clogging of filter net, and achieve the effects of reducing clogging, increasing adsorption area and ensuring dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

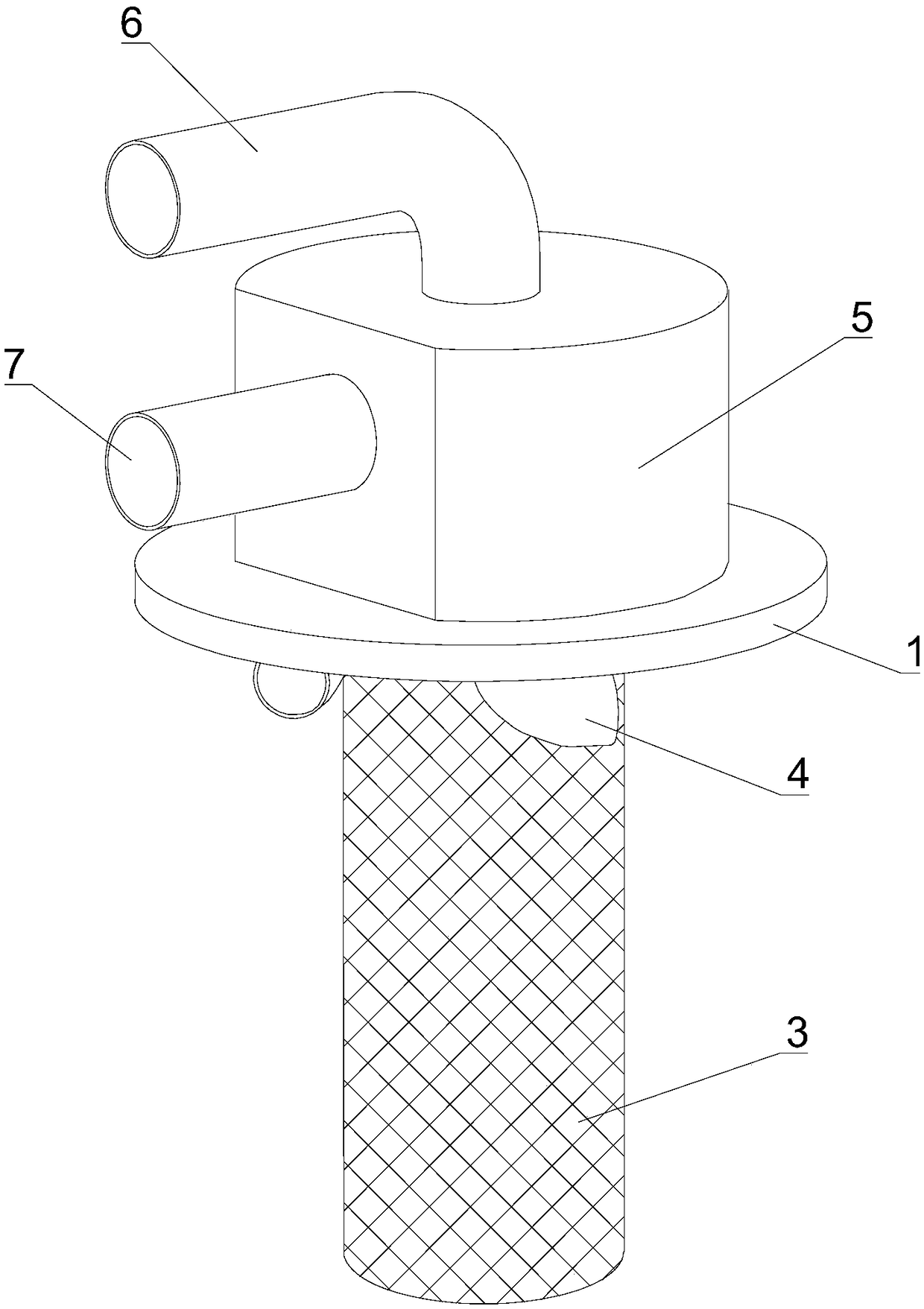

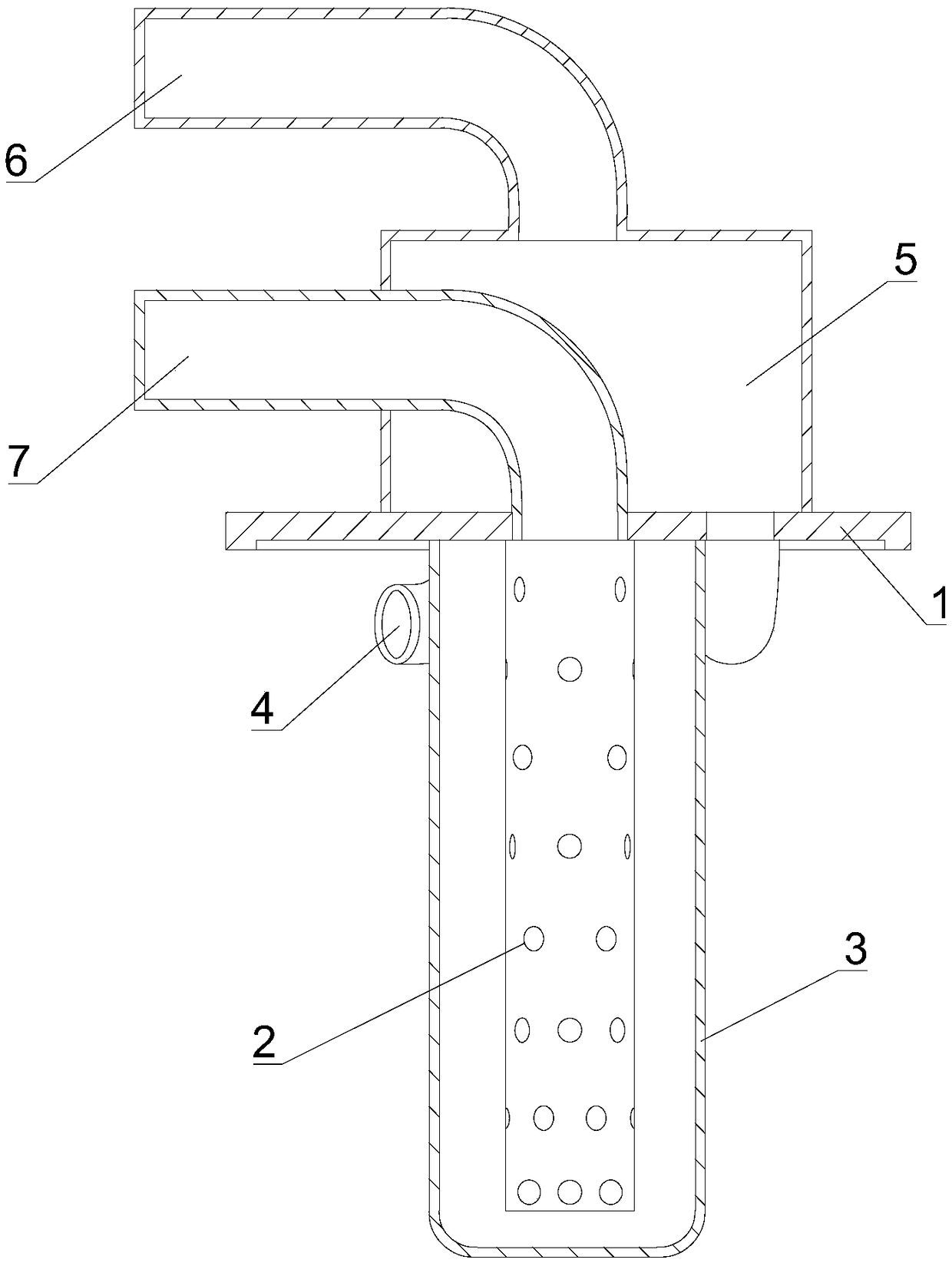

[0018] see figure 1 and 2 As shown, this embodiment provides a screw extruder dust removal hopper, which includes a barrel cover 1, a cylindrical vacuum rotary adsorber 2 is arranged under the barrel cover 1, and a filter screen cover is arranged outside the vacuum rotary adsorber 2 3. The lower surface of the barrel cover 1 is preferably provided with three feeding ports 4, and the three feeding ports 4 are arranged outside the filter screen cover 3, and a closed feeding transition chamber is arranged above the barrel cover 1 5. There are feed pipe 6 and vacuum exhaust pipe 7 protruding outward from the feed transition chamber 5. The vacuum exhaust pipe 7 extends inward and communicates with the vacuum rotary adsorber 2. The feed pipe 6 and the feed transition chamber 5. The three feeding ports 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com